Results 161 to 170 of 220

-

10-13-2013, 07:48 PM #161

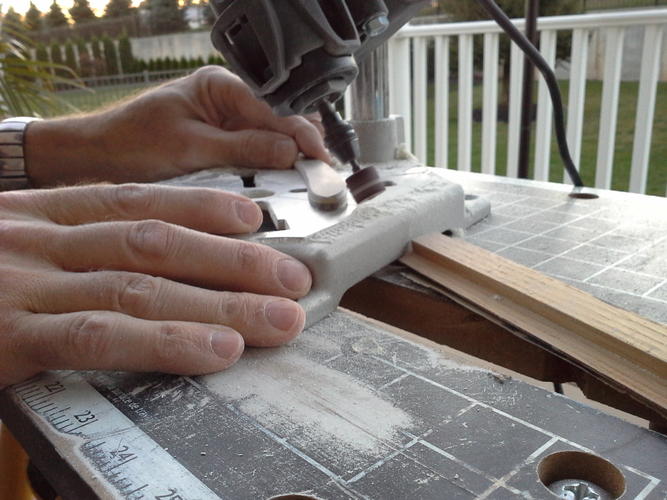

To the dremel!

-

10-13-2013, 07:53 PM #162

You certainly dont need this rig, but it makes things a little easier.

Sand just to the line. Fine sanding removes alot of material, and you dont want to overshoot, especially when trying to match an existing scale.

-

10-13-2013, 09:53 PM #163

General shape attained

Now to reduce thickness.

-

10-13-2013, 09:54 PM #164

The wood is there to guide for uniformity.

-

10-14-2013, 01:43 AM #165Senior Member

- Join Date

- Aug 2013

- Location

- bakersfield ca

- Posts

- 160

Thanked: 0

Looking great

-

10-14-2013, 12:29 PM #166

Looking good. Next time, try the thinning step before you do the contour step, especially if your edges/cuts are true. You'll have more material sitting on the bench. Just my $0.02.

---------------------------------------------------

Love new things that look old, and old things, made to look new again!

-

10-14-2013, 01:15 PM #167

I have to contour first for 2 reasons.

1, sanding down the thickness would make ig difficult to trace onto/ see the pencil line.

2 the dremel drum is not very wide. In fact it is just wide enough to do 2 passes.

I have thinned first before, using an orbital/vibratory type hand sander. That is another way to go. But I prefer this technique for these tools.

Obviously a belt sander would be the best, but for hobbyists without a ton of tools....

-

10-14-2013, 09:39 PM #168

After dremel sanding at 60 and 120, i switch to hand sanding, using increasingly

finer grits taped to a rounded stick for the inside curve, and a flat stick for everything else

finer grits taped to a rounded stick for the inside curve, and a flat stick for everything else

-

10-14-2013, 10:54 PM #169

Here I am beveling the edge of the scales

-

10-14-2013, 11:07 PM #170

Side by side 400 grit done.

110Likes

110Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote