Results 16,221 to 16,230 of 20602

Thread: What are you working on?

-

05-12-2019, 09:58 PM #16221

-

05-12-2019, 10:09 PM #16222Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

I have corrected some goofed up holes by putting a turning drill bit in and then torquing the scales to elongate the two holes in opposite directions. A little Vaseline on the pin and then fill the slop with CA, with tape on one side to keep it from running away. Once it is set, flip it and do the other side. The CA won’t stick to the pin and it corrects fairly easily. If you collars are the right size it will cover the error.

It's not what you know, it's who you take fishing!

-

The Following 3 Users Say Thank You to RezDog For This Useful Post:

Gasman (05-13-2019), JellyJar (05-14-2019), ScoutHikerDad (05-12-2019)

-

05-12-2019, 11:37 PM #16223Senior Member

- Join Date

- Oct 2010

- Posts

- 26,211

Thanked: 8626

Rezdog speaks the truth.

Something to think about is the bottom pin may be bent causing this.

Looks like the pin-hole and the top are both low on the right side of the photo.

-

05-12-2019, 11:59 PM #16224

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

05-13-2019, 04:59 AM #16225

I also cut most my pin stock down to useable size. But I keep one about 6 inches and its put in a special place so it doesn't get bent. I use it just for this reason. Testing. I'm still fixing off-set holes from when I first got into this hobby. Thanks for the info Rez. A good one to know.

It's just Sharpening, right?

Jerry...

-

05-13-2019, 05:01 AM #16226Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

I’m pretty sure that one originally came from Richard.

It's not what you know, it's who you take fishing!

-

05-13-2019, 06:22 AM #16227

A little something I put together tonight. Geneva Cutlery. The blade and scales were/are a little worn but they fit so nicely together I just had to pin them up.

A very close fit!

Last edited by Gasman; 05-13-2019 at 06:28 AM.

It's just Sharpening, right?

Jerry...

-

05-14-2019, 03:03 AM #16228

-

05-14-2019, 03:15 AM #16229

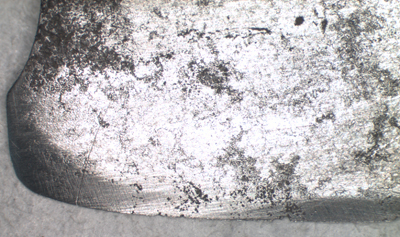

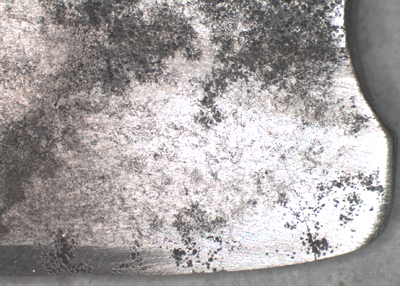

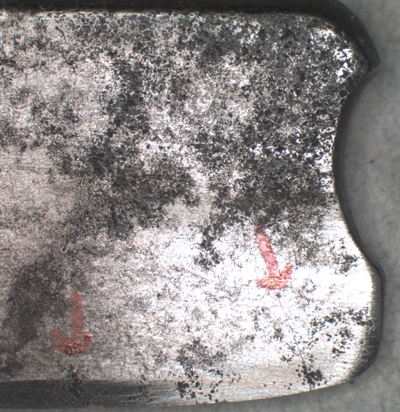

My Frederick Reynolds shows its ugly

My Frederick Reynolds shows its ugly

Had some time while some finish was drying so I pulled out my Frederick to see if it would take a bevel. Started with two layers of tape and went to three as the bevel was looking quite wide. Some of the smaller chips disappeared, but I was noticing a fair amount of pitting at the edge and then a crack showed it's ugly little face at the toe.

I think this could be saved with a bit of shortening into a spanish point but the pits have me most concerned there's several areas similar to the red arrow farthest from the tip. I'm not in a hurry on this one so maybe some high angle honing? Bread-knife? Just keep going with three layers and see where I wind up? I'm not going to mess with the tip until I know the edge is usable. Am I wasting my time? Appreciate your advice.

O'Toole's commentary on Murphy's Law: Murphy was an optimist.

O'Toole's commentary on Murphy's Law: Murphy was an optimist.

-

05-14-2019, 04:17 AM #16230Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

I have seen some amazing things with regrinds, but few people have the ability to get that much off, and keep a blade straight doing it by hand. It looks like it is beyond what I can do by hand. You may want to save that one for if you get a belt grinder or give it to someone for them to use for regrinding practice. It looks like there is a lot of ugliness and it looks like it goes deep. It may not even make a regrind. I have not reground that many blades so I am no expert.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

JellyJar (05-15-2019)

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

I hadn't noticed it before with the shorter micro bolts and pin stock. So I filled the hole and re-drilled, still a bit to the right but the blade doesn't need guiding and doesn't hit the scale.

I hadn't noticed it before with the shorter micro bolts and pin stock. So I filled the hole and re-drilled, still a bit to the right but the blade doesn't need guiding and doesn't hit the scale.

Reply With Quote

Reply With Quote