Results 71 to 80 of 153

Thread: Mini Anvil

-

05-20-2018, 01:15 AM #71

The beauty of a small anvil for pinning is that it may be held in the hand or placed on a bench top. For me, the chuck or a 4x6x1 piece of steel can be set on my right thigh to work. I AM PARTIALLY BLIND AND HAVE TRIFOCALS. THE THIGH PLACEMENT BRINGS THE LENGTH OF THE HAMMER FROM MY HIP TO THE PROPER DISTANCE TO BE ACCURATE AND SEE WHAT i AM DOING.

SORRY FOR THE CAPS!

~rICHARDBe yourself; everyone else is already taken.

- Oscar Wilde

-

05-20-2018, 11:57 AM #72

I packaged all the ones I made in a medium flat rate box.

I encased each anvil in closed cell foam, totally filling the box.

Tom thought it was a loaf of bread..!!

Maybe one of ya has a picture of thiers, as it came. Mine got washed out of my last phone, in the spin cycle of the washing machine.

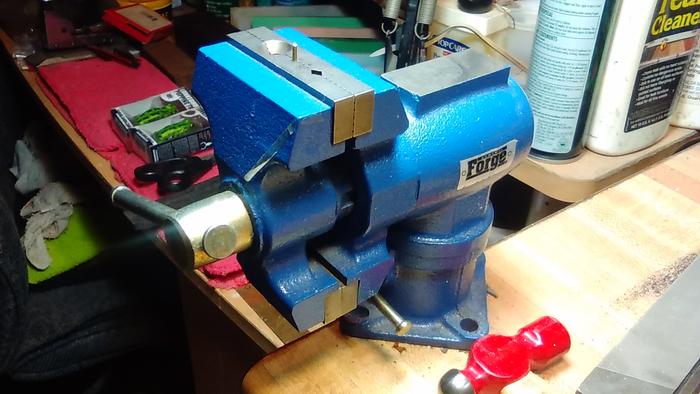

I've always liked the idea of using a drill chuck, but this little vice from HF was perfect for me, and less than $20 with a coupon. I can clamp it, or permanently attach it to a bench, has a series of holes for gripping different objects, toothed and smooth jaws, swivels and turns for any desired position, and holds a piece of 1/16 rod with the grip of god.

Mike

Mike

-

The Following 4 Users Say Thank You to outback For This Useful Post:

Geezer (05-20-2018), MisterClean (05-20-2018), spazola (05-26-2018), Utopian (05-24-2018)

-

05-20-2018, 12:20 PM #73

-

05-20-2018, 04:39 PM #74

TBH, I rarely use the drill-chuck any longer. Relying instead on a piece of scotch tape to hold my collars on till I get both ends peened enough and then remove the tape.

It seemed that as cranking the pin down in a chuck or vice was actually causing the pin to be work-hardened on the other end and the first peen done would swell much faster than the end which had been squeezed. I also found that annealing the squezed end made for a more even job, yet that was another operation to perform.

I found that I could do a more even job without it. Just me.

-

The Following 5 Users Say Thank You to sharptonn For This Useful Post:

Gasman (05-20-2018), MisterClean (05-20-2018), petercp4e (05-20-2018), spazola (05-26-2018), Utopian (05-20-2018)

-

05-20-2018, 08:19 PM #75

Nice pics of your vice Mike.

Tom, Thats good info. I hadn't noticed this yet but maybe I will look for this next time and see if its happening to me too and I just don't know it.

Another question...Folks normally peen the second side in a divot in the steel to keep from flattening. At least this is my understanding. Did anyone drill/grind a divot in the R.R.Track Anvil? Seem like it would be hard to drill. It's just Sharpening, right?

It's just Sharpening, right?

Jerry...

-

05-20-2018, 08:27 PM #76

Never used a divot. As I tap on the edge of the pin, I tilt the razor so the opposite is happening on the anvil at the same time.

Seems to do a more uniform job for me.

-

-

05-20-2018, 08:32 PM #77

I took a 4" drill press vice and made brass jaws for it. Then I use some thin cardboard like from cereal boxes ok, ok, it was from a beer case. Anyway I put a piece on both sides of center and then tightened the vice. Then I used my drill press and a 1/16" drill bit in the center. This holds the pin firm and also square.

The washer goes on and then a bit of tap tap tap and then onward.

I haven't noticed any work hardening.

I am going to put a small divot in the RR track/at least try to. I have a cheapo set of diamond coated pieces from Harbor Freight. I also have a 1/8" carbide ball mill that I might try.Our house is as Neil left it- an Aladdin’s cave of 'stuff'.

Kim X

-

The Following 2 Users Say Thank You to cudarunner For This Useful Post:

Gasman (05-21-2018), MisterClean (05-21-2018)

-

05-21-2018, 05:42 AM #78

Let me know how that goes Roy.

Tom, i like your idea. I will have to try that. I think most the time im peening i just angle the hammer around the edge of the pin and hold razor steady. I never really like the divot. Depending on the collars your using, you could be hammering on the washer and causing stress on the scales. JMO.It's just Sharpening, right?

Jerry...

-

05-24-2018, 01:47 AM #79

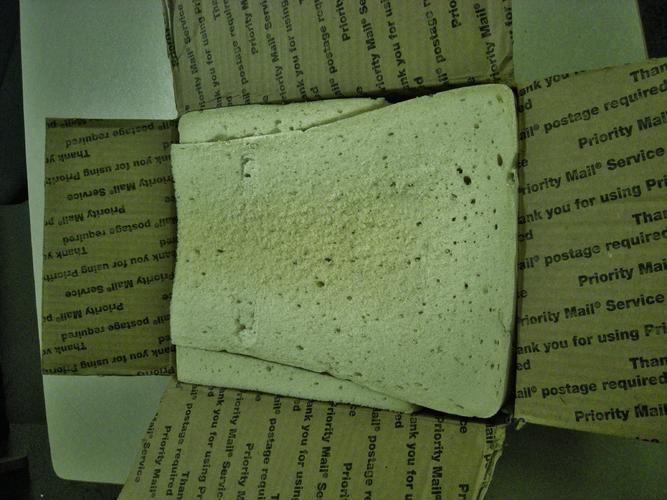

Found it. The loaf of bread with a railroad track anvil inside!

-

05-24-2018, 01:52 AM #80

That is to pretty to hit with a hammer!

506Likes

506Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote and boy they form rust quick.

and boy they form rust quick.