Results 7,971 to 7,980 of 9139

-

06-20-2020, 12:59 AM #7971

While it's not 'Directly' associated with Straight Razors

--- I had a new toy land at Ski's today.

--- I had a new toy land at Ski's today.

I had purchased an 8" Harbor Freight 20 or more years ago. I was never happy with it as it was sloppy as hell but it would put holes in things.

I finally decided to upgrade a bit and this landed today. (Seller's Pic) It's a WEN 4214 12-Inch Bench Mount Variable Speed Drill Press. The variable speed doesn't require changing a belt over pulleys which will be most welcome.

Once I got it home my son arrived and helped unpack it. While I'm no Tc with Gorilla Strength I'm not too shabby but I'll be honest in that it was nice to have a bit of help to get the overhead with the motor attached on the shaft as the cabinet it was being assembled on was already almost 3 feet high.

I'd watched a video on this machine and the poster had found the quill running almost dead true but the stock Keyed Chuck about 10 thousandth out so being a bit anal I purchased an entry level Dial Indicator and Magnetic Stand to check things out. I figured I could use it to check other things like my disc brake run out on my Harley.

To make a long story a bit shorter, I email Geezer for some advice on using the indicator and he also added sage wisdom about cleaning the quill and chuck.

I struggled to get consistent results using the bracketry and finally just used the vertical post on the magnetic base and 'Viola'! Consistent results!

The quill measures 1/2 a thousandth run out and the chuck holding a new Made In the USA drill bit has a run out of 2 thousandth.

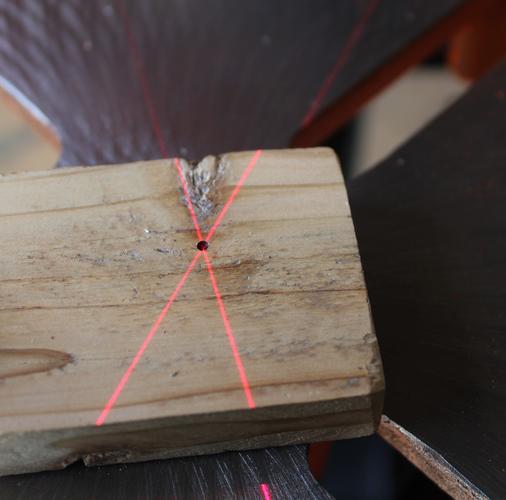

I still need to adjust the table to be 90 degs to the drill chuck and the laser to be on center of where the drill bit is to start cutting.

So far and for about $370 delivered--I'm one happy camper

Note:

I just finished adjusting the table and the laser. The table was spot on but the laser was way off. I will say that it was very interesting adjusting the laser. I quickly found that everything must be tightened fully or there aren't repeatable results AND that it doesn't take much to move the beams/having to compensate for the tightening of the set screws for one.

With that said it's all good to go!

Last edited by cudarunner; 06-20-2020 at 01:55 AM.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

06-20-2020, 06:37 PM #7972

Really nice drill press, Roy!

There are many roads to sharp.

-

06-20-2020, 07:21 PM #7973

Thanks my friend

so far I'm just tickled shiteless with it.

so far I'm just tickled shiteless with it.

I messed up and hadn't centered the quill on the center of the hole in the table and boy was that head tight on the shaft and I hadn't even tightened down the set screw to hold it in place I finally got it to move over and got the set screw tightened up and rechecked everything and I did have to re-do the laser but the run out is just like it was.

I finally got it to move over and got the set screw tightened up and rechecked everything and I did have to re-do the laser but the run out is just like it was.

While it wasn't available all those years ago I can't believe that for $370 delivered it has the quality that it does. I also can't believe that I put up with that HF as long as I did. I put the same drill bit in the old HF and set up the dial indicator and I could move the chuck 15 thousands both ways I couldn't get a reading on the Wen.

I couldn't get a reading on the Wen.

When I bought that HF all those years ago my best friend was visiting from Southern California and he thought it would work good enough for him so when he got home he bought one.

He once said something about it was nice to have a drill press kind of like his dads. I told him that our drill presses were toys and that Pop's was a tool. I believe it was a Vintage Delta.Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

06-21-2020, 09:57 AM #7974

Nice one Roy. Mine is a Craftsman but ive never tried to measure the runnout. Sounds like your all set up for drilling.

It's just Sharpening, right?

Jerry...

-

06-21-2020, 12:31 PM #7975Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

Like to see new tools being trialed Roy.

Seen the wen name on a few sites And I hope it works for your needs buddy.

I have a tabletop drill press as well and find the only time it’s a pain is when you adjust the table height.

Looks like your, like mine doesn’t have a crank and track for table adjustments, so every time we go up or down, near everything needs to be retrued.

Love mine, despite the above for pen blanks and brush handles.

Enjoy it.."Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

06-21-2020, 03:02 PM #7976

Wow! i've never heard of Wen before now. I checked out their web site and they have some impressive prices. (they even have a metal lathe!)

-

06-21-2020, 03:53 PM #7977

Oh but it does have the crank and track--------------------------

Ski has a Jet floor model and that rack and pinion is nice and tight but still easy to raise and lower. The Wen is a bit sloppy but it is real smooth. The mechanism on both Ski's and mine locks the same way, just like the old HF did--a crank that pinches the unit tight to the vertical post.Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

06-21-2020, 07:22 PM #7978Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

Nice Roy!

Neither my tabletop or floor model have the crank table actually. Really wish the floor model did as I have the compound vice mounted on that one and it weighs a bit.

Maybe if I rip apart our treadmill after our son moves out I might find the guts to make a power table quill.

Couple o More years I figure.."Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

06-21-2020, 08:09 PM #7979

I've been playing with my new toy and I've found that when the table is raised and lowered the laser cross hairs aren't aligned where they were. I was thinking about you and having to reset for your pen turning.

When I was setting the laser up I clamped a small piece of wood to the table and drilled a shallow hole with a 1/16" drill bit then used a very thin (smaller than the drilled hole) marks a lot type pen to darken the hole to make it easier to see to align the cross hairs.

So when I found that the cross hairs no longer aligned I found that if I aligned the cross hairs and then left the wood with the hole in it in place and then raised or lowered the table there was just enough movement in the mounting point that I could re-align the cross hairs and tighten the clamp to keep it all aligned.

Probably much ado about nothing but----------------------Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

06-22-2020, 02:43 AM #7980

Another Wade and Butcher Special.

Well on my way to that 7 day set. This makes 5 with the engraving on the blade face. I have 1 more with the engraving on the tang but I want them to all be the same. Still need to work on the etching for the days of the week on the spine.Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

28620Likes

28620Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote