Results 11 to 20 of 155

Thread: Is this microchipping...

-

12-27-2015, 08:41 PM #11illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

This is not a matter of semantics and calling it another word does not alter this.

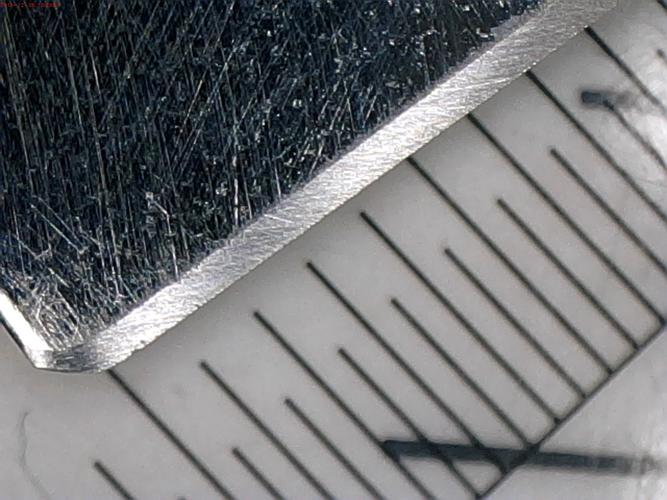

When a blade is worn down, the edge can begin to be affected by the stabilizer, causing the stabilizer to make contact with the hone which causes the heel end of the blade to be lifted off of the hone. That is not the case with a Union Cutlery Spike, as it has no stabilizer, or shoulder, or anything else extending onto the blade anywhere remotely near the edge. There is nothing impeding the contact of the blade with the hone. That is apparent by the wider, rather than more narrow, bevel at the heel on one side of the blade and the relatively uniform bevel width on the other side. There is no need or reason to alter the shape of the heel.

PCM, just a couple of strokes on the side of a hone will be sufficient to remove that hint of a spike, or hook, that may form at the heel. Given the condition of the edge I would suggest that you drop all the way down to a 1k hone if you have it and get the bevels meeting along the entire length of the blade. IF you feel that the shoulder of the tang may impede your honing, then just hone at a 30-45 degree angle (heel leading) and the shoulder will never come near the hone. Tape or don't tape, either will work out.

-

12-27-2015, 11:50 PM #12

-

12-28-2015, 12:00 AM #13

I'll definitely tape. It had some wear on the spine before I got it, and my earlier attempt at honing this blade wore it more, until I asked on the forum and found I was using too much pressure. I then used tape, and on my most recent honing I used tape on that blade, and really light pressure.

I have a Norton 1/4/8k stones and a Naniwa 12k SS, so I can go to 1k. Should/can I do anything about the uneven bevel wish on the left (when looking at the edge) side?Regards,

PCM

-

12-28-2015, 01:45 AM #14illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

Don't worry about the width of the bevel. Your can't put steel back on the spine. You could do some fancy taping but it's not really worth the bother.

Two things about pressure:

First, you CAN use pressure during bevel setting but you need to reduce the pressure near the end of the time on the 1k. You also need to monitor the wear on the tape and change it well before the tape has worn through to the steel. Before moving up to the 4k, do 15-20 light strokes on the 1k with fresh tape to make sure that you are reaching the edge.

Second, remember that the pressure on the spine and blade are not the same. There should be a slight torquing of the blade so that more pressure is on the edge rather than the spine. You are trying to remove steel from the bevels forming the edge and the spine simply serves as an angle guide, so keep the pressure light on the spine.

-

The Following User Says Thank You to Utopian For This Useful Post:

pcm (12-28-2015)

-

12-28-2015, 07:29 AM #15

I second everything Utopian said. I would downstroke it on a glass and reset the bevel on a 1k. I'd hone that blade straight into the heel because there is no stabilizer. You could round the heel if you like but it's not something that needs to be done. Gently soften the point that is formed with a few light strokes on the hone(optional). Tape or don't tape, but I see no need for more then one layer as the bevel is complete on both sides.

Last edited by BeJay; 12-28-2015 at 07:35 AM.

-

The Following User Says Thank You to BeJay For This Useful Post:

pcm (12-28-2015)

-

12-29-2015, 12:47 AM #16

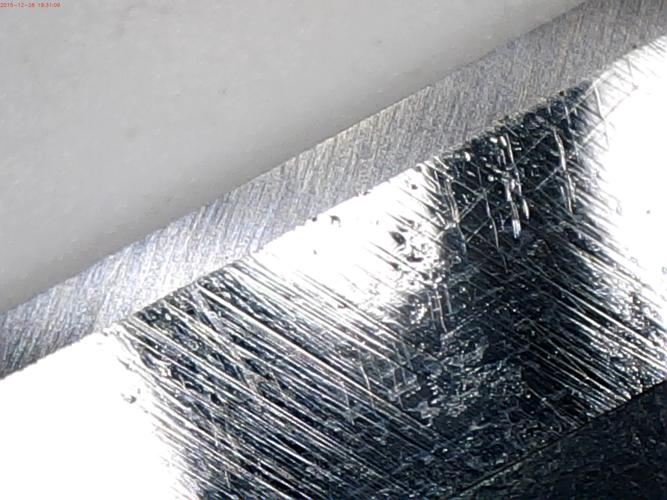

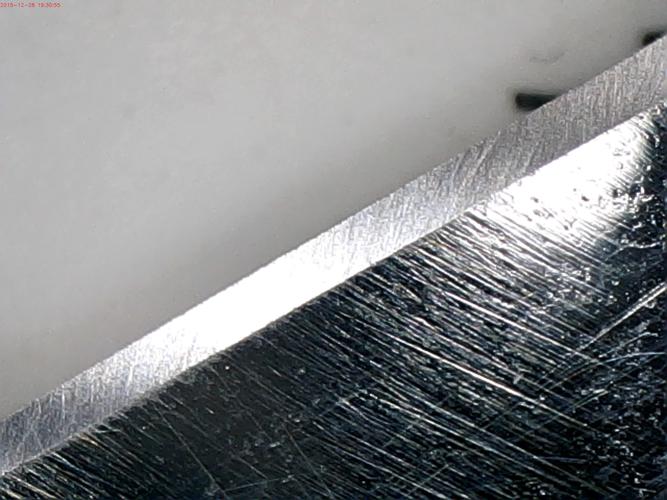

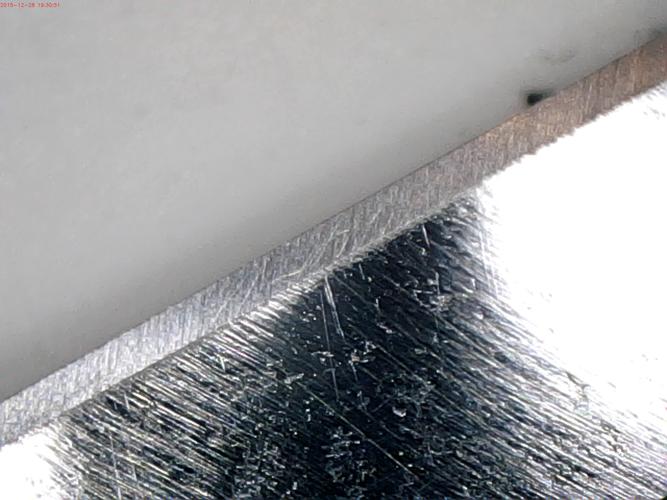

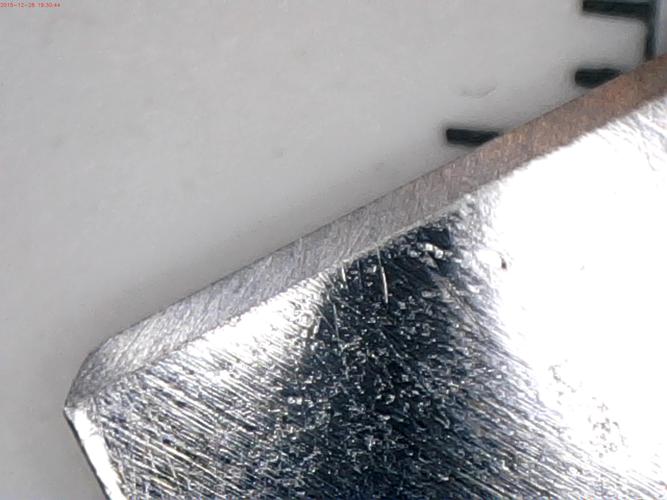

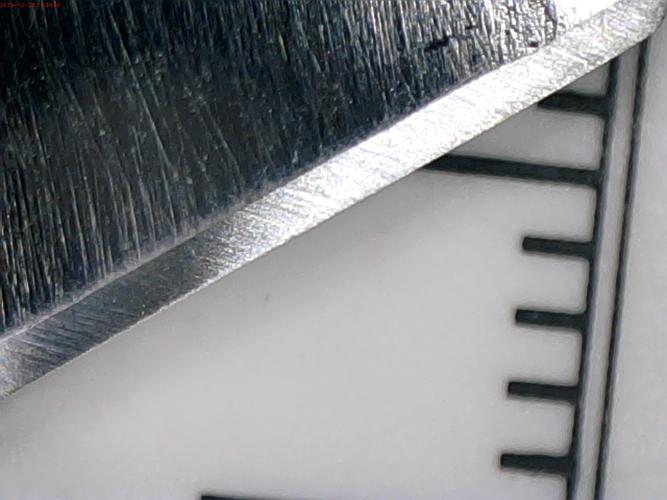

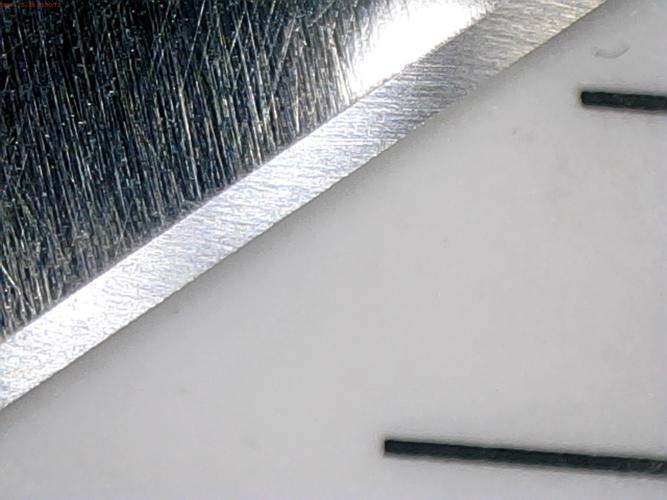

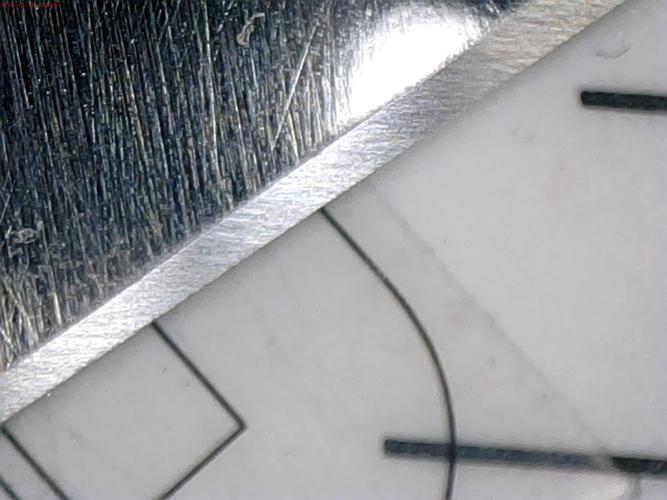

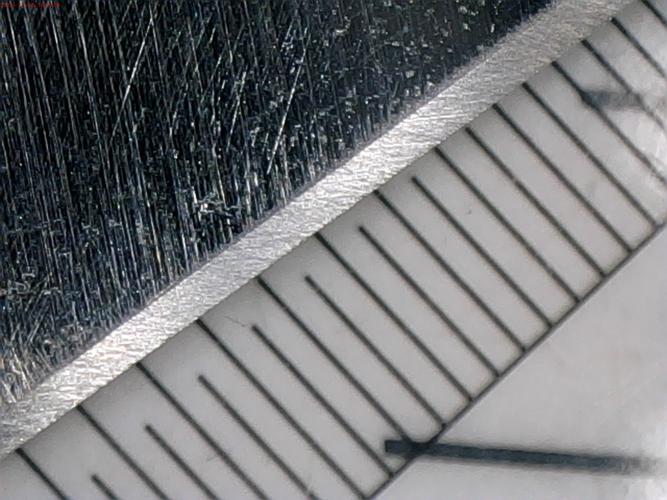

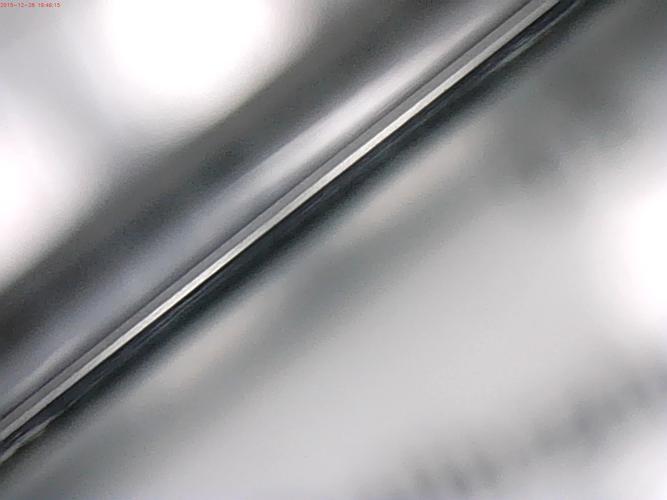

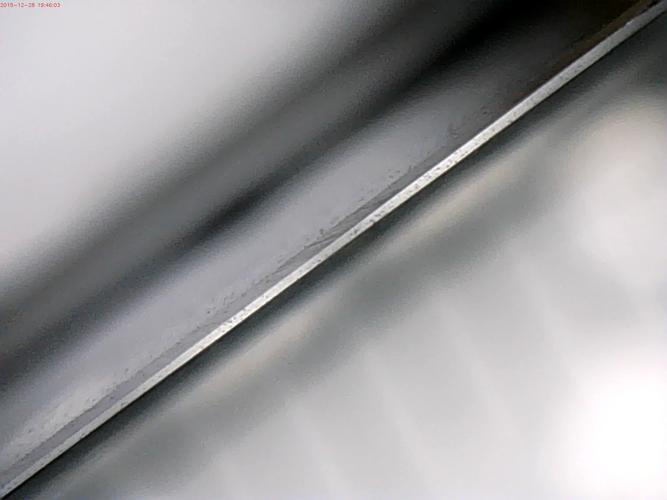

OK, I used 1 layer of tape, and went to the 1K doing heel leading X strokes. I applied some pressure for the first 40 strokes or so, and then no pressure for another 40 or so. I inked the bevel and checked and it was all coming off, except for the last 0.5 cm on the heel on the right side (when looking at the edge). I did more strokes, with my finger on the edge at the heel, when going away from me. It looks better, but you can see it doesn't quite get honed. The rest looks pretty good (as far as stria). Here are shots:

The edge seems to be meeting pretty good. I don't see any shiny spots on the edge:

Any suggestions on the progress so far?

Do I need to work on that heel more? Applying pressure like I did on that right side honing, at the heel?

Thanks!Regards,

PCM

-

12-29-2015, 01:12 AM #17illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

That wider bevel at the heel on one side is either due to a slight grind flaw or else a thinner spine there. In either case, since the edge is not fully complete there, you can either do a little more honing focussing more pressure on the heel, or you can ignore it. Do you shave with that last half cm?

Also, did you replace the tape before doing the light strokes? It is critical that you finish up with a fresh piece of tap to make sure that you are reaching the edge.

-

The Following User Says Thank You to Utopian For This Useful Post:

pcm (12-29-2015)

-

12-29-2015, 02:45 AM #18Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Looks like more than .5cm, about a half inch on the heel and at the toe, that are not fully set, yes they are meeting, but look at the stria at the edge.

Joint the edge and reset the bevel, you may have to add pressure on the heel to compensate for the spine that was ground at the heel from ridding the shoulder.

You want to hone the whole edge, so you can use the whole edge. More importantly the edge is not fully set and may fail at the higher grits.

This is exactly where most new honers have a problem in a rush to set the bevel and move on without a fully set bevel, you will pay for it later spending more time setting the bevel on a high grit stone. Do it right the first time, it’s not a race.

Either more time on the hone or two layers of tape to fully set the bevel.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

pcm (12-29-2015)

-

12-29-2015, 03:09 AM #19

You can see that most of the edge looks good but the heel is not set. This is a perfect opportunity to practice some testing. Magnification is great but the TNT and TPT will give you a better idea of what's going on. You say you've done 80 strokes. It looks like your bevel is coming in just fine but it needs more work. Any extra pressure on the heel should be pretty light. You may just have to remove some steel from the entire length of the blade to get the heel to come in evenly. This doesn't look like a particularly tough or tricky blade, it just needs a little more work. Do a TNT and you'll see the difference between the heel and the rest of the blade. Keep going until the heel feels like the rest of the blade.

-

The Following User Says Thank You to BeJay For This Useful Post:

pcm (12-29-2015)

-

12-29-2015, 12:24 PM #20

47Likes

47Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote