Results 10,201 to 10,210 of 20600

Thread: What are you working on?

-

08-05-2017, 11:56 AM #10201

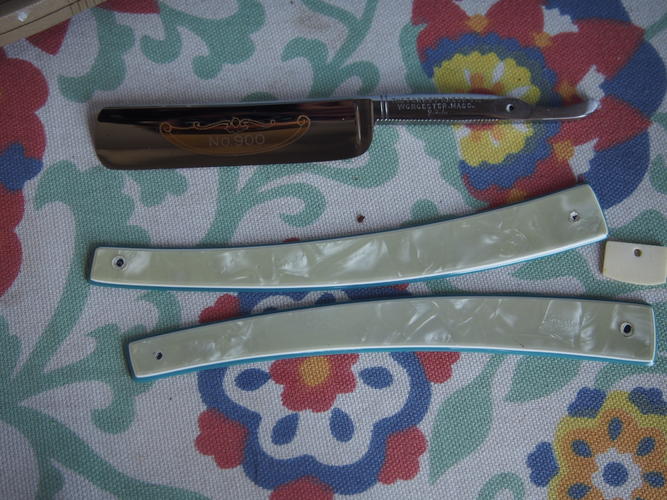

[QUOTE=jseitz;1759520]My first razor restoration projects keep advancing, slowly, as I find time. I've cleaned the blades, made the scales, polished them up, and have shaped and fitted the wedge and have them mocked up. I rushed the squared off scales a bit and could have done a bit better for shaping and symmetry, but the rounded scales came out pretty decent I think for an amateur. Just have to get some pinning materials and basic tools, try my hand at peening, and then they should be ready for the hones and a shave--really looking forward to it!

Damn fine job, blows my first outta the water.

Keep it up, refine it down. [emoji482]Mike

-

The Following User Says Thank You to outback For This Useful Post:

jseitz (08-05-2017)

-

08-05-2017, 03:22 PM #10202

-

08-06-2017, 12:57 AM #10203

It's a trick I learned from MikeB52 when I got my first set of horn blanks -- they were warped and I was worried about that, but he pointed out that a slight warp is helpful, and I soon learned how right he was. So I've done it this way a few times and I like it. I do it with wood scales too.

-

The Following 2 Users Say Thank You to jmabuse For This Useful Post:

Dieseld (08-06-2017), ejmolitor37 (08-06-2017)

-

08-06-2017, 09:40 AM #10204

Oh...so Mikes keepin secrets, eh.!!

I see how he is, now.! He must have been a US citizen, and deported for holding back valuable information to the community.

" INFO HOARDER" !!Mike

-

08-06-2017, 01:48 PM #10205

-

-

08-06-2017, 05:48 PM #10206I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

Outside on the front porch watching the kids, decided to take advantage of the the time. Was able to take apart this Torrey and get the scales and blade all polished up. It's going to be a beaut when I get it back together.

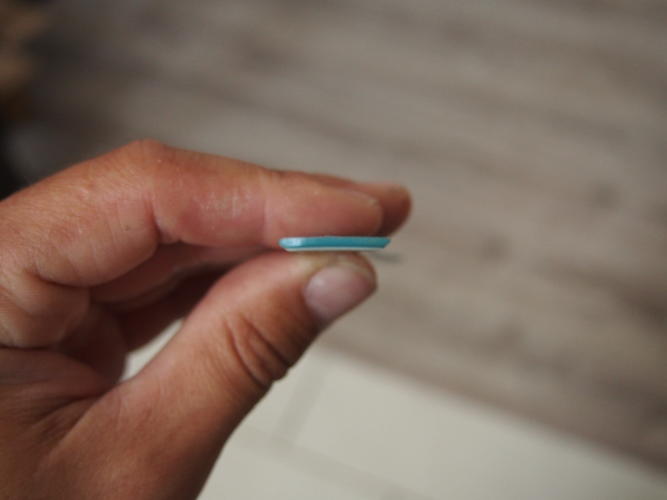

What do you guys do when the scales are cupped, and want to refit the wedge???

Last edited by HARRYWALLY; 08-06-2017 at 05:51 PM.

Burls, Girls, and all things that Swirl....

-

08-06-2017, 05:55 PM #10207

I think I know what you mean by cupped.....Makes for a tight-fitting wedge if slightly cupped on the inside.

If 'cupped' to the outside, a test-fit will allow you to sand the liners down there a bit to get things tight and even.

-

The Following User Says Thank You to sharptonn For This Useful Post:

Geezer (08-06-2017)

-

08-06-2017, 06:00 PM #10208I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

Ok, that was my plan Tom. It's cupped to the outside, so I'll have to sand it down a bit. Hopefully not to much material needs to be removed.

Sent from my LG-K121 using TapatalkBurls, Girls, and all things that Swirl....

-

08-06-2017, 06:29 PM #10209

-

08-06-2017, 06:32 PM #10210I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

Aha. Good call Tom. I may try this method first.

Sent from my LG-K121 using TapatalkBurls, Girls, and all things that Swirl....

91543Likes

91543Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote