Results 15,471 to 15,480 of 20565

Thread: What are you working on?

-

02-18-2019, 04:51 AM #15471

Damn! Don't you ever get tired, Jerry?

-

02-18-2019, 06:13 AM #15472

I only get so much time out of the truck, so I go full bore until I can't stay up no more. Ha.

I decided the epoxy was pretty solid so I sanded and shaped the end and divot. Looks pretty good. Broke out the hair dye and thought I might wait for tomorrow for that stuff. Bet it stinks! Hate to wake the house up with the smell.

Now I'm helping my computer god/friend with his Server. I'm trying the DL a movie from his server across town for a test. Hope to be watching a Startrek movie shortly.It's just Sharpening, right?

Jerry...

-

02-18-2019, 11:34 AM #15473

Just a drop of CA

Mike

-

02-18-2019, 11:49 AM #15474

Jerry, u can save time sanding, if you'd laid the scale with the flat side down. Make the filler thicker than peanut butter, so it doesn't ooze out.

Only sanding needed would have been the top and edges.

If your going for a shiny finish, you'll have to slightly dish out the repairs and top with CA. Epoxy won't polish up.!Last edited by outback; 02-18-2019 at 11:53 AM.

Mike

-

-

02-18-2019, 11:58 AM #15475

I'm the same. I like using a Emory board/ fingernail file, for that. Less chance of hitting the scales.

Mike

-

02-18-2019, 02:22 PM #15476Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,449

- Blog Entries

- 1

Thanked: 4206

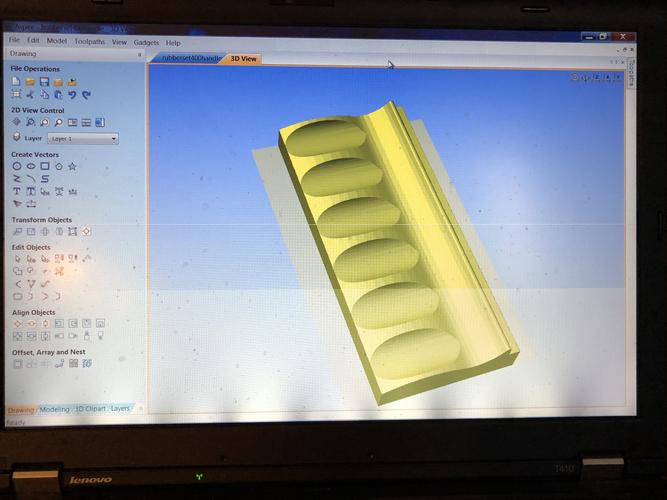

With snow in the air I’m sorta home bound this holiday Monday.

Just about ready to try to crank out a shaving related project on my lil robot.

Been a slow road to this point, but the beauty of data and CAD is that all those steps don’t need to be retaken going forward.

By designing everything in 2d, or 2.5d as some consider it, then splitting the sections into base and cap, then rolling everything back to 4th axis rotary I should be able to make one, or two piece handles with consistency, tight tolerance, and repeatability.

Two different materials can easily be worked together. Not to mention the original did have a two piece design and to honor the original I’d just like to keep the option.

Cheers gents.."Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

-

02-18-2019, 04:26 PM #15477

It was my first try with epoxy that actually worked. Thanks for the tips guys. I hadnt thought about the epoxy not polishing. But, CA doesnt dye right? So should the CA go on before or after the dye?

I tried to tape the scale down but it wouldnt stick to the parchment paper.It's just Sharpening, right?

Jerry...

-

02-18-2019, 09:02 PM #15478Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,449

- Blog Entries

- 1

Thanked: 4206

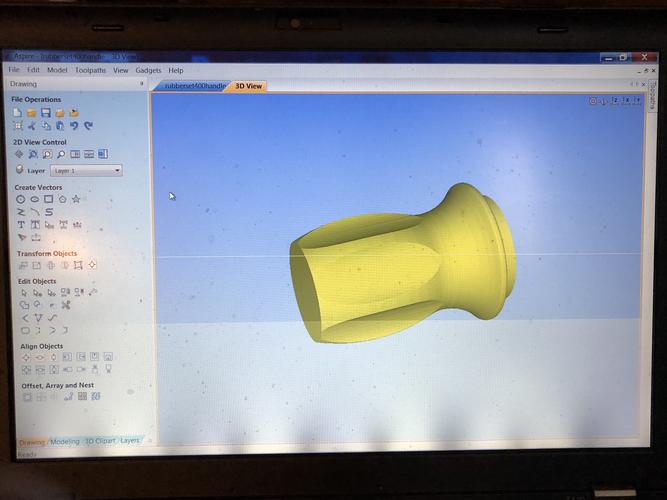

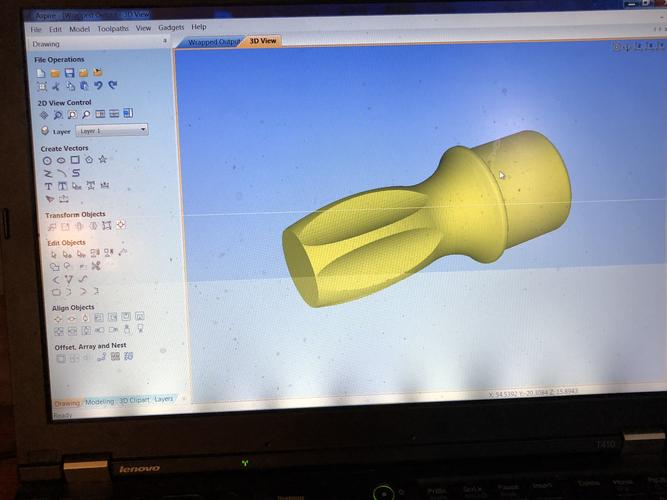

So, I’m thinking this is working. Kinda cool..

Rough passes to get everything true with a 3/8 ball nose bit.

Now the finishing passes with a .25 mm tapered ball joint tipped bit.

With a whopping 1/32nd of a mm step over each pass, this shall take hours to complete.

Particularly proud that I was able to switch tool bits mid project and seemingly not foul up my reference points and tool length distances.

Cheers.

Last edited by MikeB52; 02-18-2019 at 09:06 PM.

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

02-18-2019, 09:42 PM #15479

I bet that would be tricky changing bits and keeping the same exact length. Those machines are just beyond my thinking abilities.

It's just Sharpening, right?

Jerry...

-

02-18-2019, 09:52 PM #15480

--Mike, awesome project, I love seeing those pics of your machines at work. It's one of those bucket list tools/skills, to be able to create like that.

Here is my new favorite brush.. I think you will recognize your work.. Thank you! I gotta say that the knot was set at an excellent depth, a first for me.

--Outback, The CA with bog oak dust is prefered over epoxy in all cases?

I just came over to my brothers house and his wife was throwing some things out... This hair straightener has a dial for 250 degrees up to 450.

I think it may work fantastically! (May not)

What temp should I set it to?

“You must unlearn what you have learned.”

“You must unlearn what you have learned.”

– Yoda

91447Likes

91447Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote