Results 20,471 to 20,480 of 20573

Thread: What are you working on?

-

02-20-2024, 03:00 PM #20471Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,448

Thanked: 4829

I love the silver colour on old scales. The blade looks pretty good.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

PaulFLUS (02-20-2024)

-

02-20-2024, 06:42 PM #20472

Outstanding Paul!

Semper Fi !

John

-

The Following User Says Thank You to Johntoad57 For This Useful Post:

PaulFLUS (02-20-2024)

-

02-21-2024, 02:34 AM #20473

Really neat! I dig old razors from exhibitions, fairs, events, ships, hotels, etc.

I actually have a razor from the same event, made by John Heiffor.

It is from the Horticulture Exhibition"Don't be stubborn. You are missing out."

I rest my case.

-

02-24-2024, 03:41 PM #20474

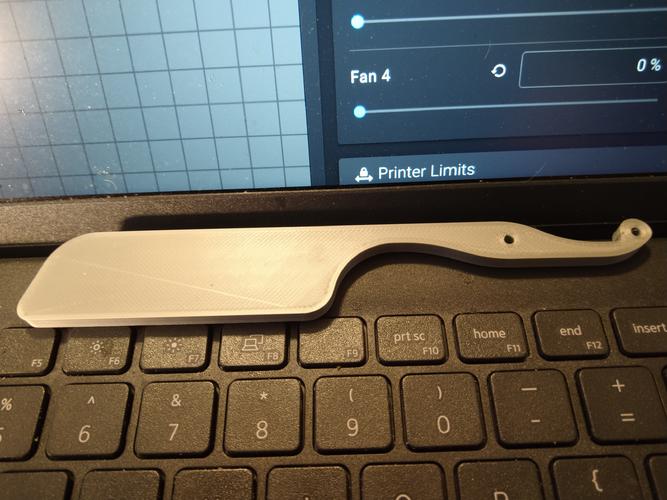

Plastic razor? I know, right? What is CCR even THINKING?

Actually I just got a laser engraver and I was going to use it to etch outlines on some 1095 and MagnaCut bar stock, for cutting, and maybe put a makers mark on the finished razors. But you know a drawing in 2D sometimes just doesn't work right in 3D and I wanted a certain fit in the hand, so I 3D printed this guy up after printing and tweaking a few other versions. I think the laser is going to be a game changer. Plus I got a whole new grinding setup in the works, so that got me thinking about some new razors. Plus after all these years there are still a couple of guys bugging me to make them razors and finally my workload is starting to go down a little.

I am looking forward to playing with the MagnaCut. Last time I tried to do a SS razor it was 440C and yeah it was okay, but somehow it just didn't feel right on the face or on the stones. This new supersteel has me sort of excited. I might try some CPM S35VN, too. My little Paragon oven goes up to 2000°F which is right at the lower range for HT on both of those steels but it does a good job on carbon steels like 1095.

I still got a couple hundred Gold Dollars, too, and I might churn out some 3D printed scales for some of them and kick them out the door. I did a few sets about 10 years ago and they came out okay.

-

02-25-2024, 05:22 PM #20475

Could always forge a few of those GDs together, make a real razor from them, too.

Mike

Mike

-

02-25-2024, 06:18 PM #20476

HAHAHAHA! Yeah I could but probably never will. If I am going to make heat and beat razors I think I will use steel with a better pedigree. These days I am all about stock removal. But if someone out there will do it on a dare, then I hereby officially dare anyone to have at it. I'll sit in the shade with a beer and watch.

-

03-02-2024, 05:43 AM #20477

Put the S. Crookes & Son back together tonight. I felt like I could have done more to the scales but I just really needed to get this thing finished...ANYTHING finished really. I have too many in the drawer partly done and I am literally running out of room in it. Same scales, wedge and collars except for one that was missing on the pivot end. Fortunately I had plenty that match.

I talked about filling the oversized pin hole but the pivot hole in the blade was a little enormous also so I decided to sleeve the holes in the scales right through the blade.

That also helped to center the blade so no more funky washer under the scale. I don't like the way that looks anyway.

I managed to keep the blade a hair over 8/8 and keep the bevel angle right even with all the sanding to get rid of the pits and hone wear not to mention those really deep scratches on the blade face from a previous sanding attempt.

Over all I'm happy, if for no other reason than to take one off my list.

Before:

After:

I think that streaked and sunburst horn looks good on that blade.

Now to hone that bad boy up and test shave it.

-

03-02-2024, 10:49 AM #20478

Came out great, paul

Mike

-

The Following User Says Thank You to outback For This Useful Post:

PaulFLUS (03-02-2024)

-

03-02-2024, 11:06 AM #20479

Nice work Paul.

It's just Sharpening, right?

Jerry...

-

The Following User Says Thank You to Gasman For This Useful Post:

PaulFLUS (03-02-2024)

-

03-02-2024, 03:08 PM #20480Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,448

Thanked: 4829

Looks good Paul.

You put the sleeve right through the scales, so I am guessing it stops short of the collar ever so slightly so you can still get the scales nice and snug against the blade.It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

PaulFLUS (03-02-2024)

91473Likes

91473Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote