Results 16,361 to 16,370 of 20602

Thread: What are you working on?

-

05-28-2019, 03:33 AM #16361

“You must unlearn what you have learned.”

“You must unlearn what you have learned.”

– Yoda

-

05-28-2019, 11:53 AM #16362Senior Member

- Join Date

- Feb 2015

- Location

- Duluth, GA - Atlanta OTP North

- Posts

- 2,546

- Blog Entries

- 1

Thanked: 315

-

05-28-2019, 05:02 PM #16363

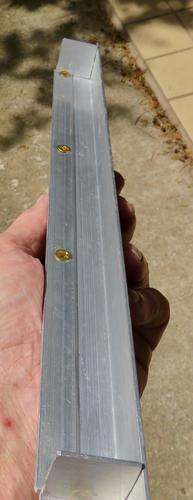

Tom, was this what you were talking about for wedges? I made it about 1 1/2 yrs ago when I was talking about making wedges out of Cerrobend. Cerrobend retains its shine rather than becoming dull looking like lead. It melts very easily as you may know.

I made a long strip of it by placing wedges under the part with the thick side under the piece that is screwed in which tilted it a tad. It worked okay but could use some perfecting. Having the long piece, I was able to break or cut a piece off but this one was for a normal sized razor. For ones with larger blades like FBU's & so on, the wedges need to be a little longer. I like the way with the 2 blocks of wood put together but this could be made a little better.

If perfected, different thickness wedges could placed as I mentioned to make thicker wedges. I had to pour the Cerrobend carefully or it would flow over the piece screwed in.

I actually thought of an idea in which I could make a top for it sealing the Cerrobend in using something like a piano hinge or shorter hinges with a flat piece of metal screwed in the top of it on the screw side & fabricating a piece near the top with a screw going through a hole on the back "wall" & another tapped hole in the piece attached to the hinge(s) so that out could be adjustable for thinner or thicker wedges if ya know what I mean. I'm sure there could be a simpler way of making them but this was a way to make several in one whack! This was like I said, about 1 1/2 yrs ago. It sounds primitive so I know there's a better way. I'm sure some of you great guys could make a better one.Last edited by engine46; 05-28-2019 at 05:24 PM.

-

The Following User Says Thank You to engine46 For This Useful Post:

Geezer (05-28-2019)

-

05-28-2019, 06:32 PM #16364

Mike-I just fell down the Cook Woods rabbit hole thanks to you. They are having a sale on Claro Walnut burl blanks. Suffice to say I spent more than I care to admit on some of the most gorgeous wood I've ever seen-16 pages of wood pron on just the walnut burls! I picked up some more African Blackwood too, as I'm hoping to do a razor/brush combo in that material. It's looking more and more like the "summer of wood" for me after my various acrylic, paua, horn and bone phases.

The thing is, though, they wanted $35 for just a few custom cuts, so I just ordered a couple of turning blanks as is, and I'll cut them myself if necessary.

Thanks again for the tip! AaronThere are many roads to sharp.

-

05-28-2019, 06:50 PM #16365

Cutting does waste some wood, but the offset in cost makes it worth it.

Sounds like some nice pieces ordered. Im still trying to work thru the last of what i have in stock. Not the best stuff but they work. When i get thru them i might look into buying some burl. I haven't worked with that yet.It's just Sharpening, right?

Jerry...

-

05-28-2019, 07:01 PM #16366

Jerry-With burls you generally want to have it stabilized, especially at razor scale thicknesses. I am waiting on some red mallee burl to get the Cactus Juice treatment by a knife-maker friend of mine, and then I plan to back it with .030" black G10 per the advice I got on here, as even stabilized, it can still be very brittle. But it works and shines up beautifully!

I'll report in when I'm working on this project, as I'll probably have a few technical questions. Later-AaronThere are many roads to sharp.

-

05-28-2019, 09:50 PM #16367

Got home from work today to find a few project razors in the mailbox. From left to right are a Timor, a Wilburt Cutlery(made into a shorty some time ago), an Ern Crown & Sword and a Joseph Smith and Sons(with roached horn scales). These should keep me busy for a short time and I'm sure will all be nice shavers.

-

05-28-2019, 11:24 PM #16368

That Timor is looking a little rough on the edge. Good luck with it. The rest look like nice razors that will come to life without too much effort.

Aaron, Ill be watching. And the liner sounds like the safest way about it.It's just Sharpening, right?

Jerry...

-

05-29-2019, 12:36 AM #16369

I was concerned about the Timor as well. Did a quick clean on it and the pitting does go into the edge in a couple of places. The rest just comes really close to the edge. I honed it up anyway and the edge seems fine, but I'm prepared for it to be a little uncomfortable when I test shave it.

-

05-29-2019, 09:30 AM #16370

Okay, now that I'm upgrading my blades and bits, say I want to get a better ripping blade for my 10" table saw for ripping blanks of exotic hardwoods. I'm hoping to get really fine cuts, hopefully no more than 1/6" thick (though 1/8" would be perfect-not sure that's realistic or even safe on a table saw?). I subscribe to the adage "Buy once, cry once." What do you more experienced woodworkers recommend?

There are many roads to sharp.

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote