Results 16,341 to 16,350 of 20573

Thread: What are you working on?

-

05-25-2019, 02:15 PM #16341Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,443

Thanked: 4828

I did not exactly follow all that either Mike, but what I took from it is that it won’t be a stable size for up to 200 hours. So if Tom is going to make some long strips it will be fine. I also imagine that amount of expansion is pretty tiny on something the size of a wedge.

It's not what you know, it's who you take fishing!

-

05-25-2019, 03:34 PM #16342Senior Member

- Join Date

- Feb 2015

- Location

- Duluth, GA - Atlanta OTP North

- Posts

- 2,546

- Blog Entries

- 1

Thanked: 315

-

05-25-2019, 03:49 PM #16343Senior Member

- Join Date

- Feb 2015

- Location

- Duluth, GA - Atlanta OTP North

- Posts

- 2,546

- Blog Entries

- 1

Thanked: 315

I like the idea of a small mold you can put some lead in and, to quote Barney Fife, "pow pow pow." I believe that is what someone mentioned earlier.

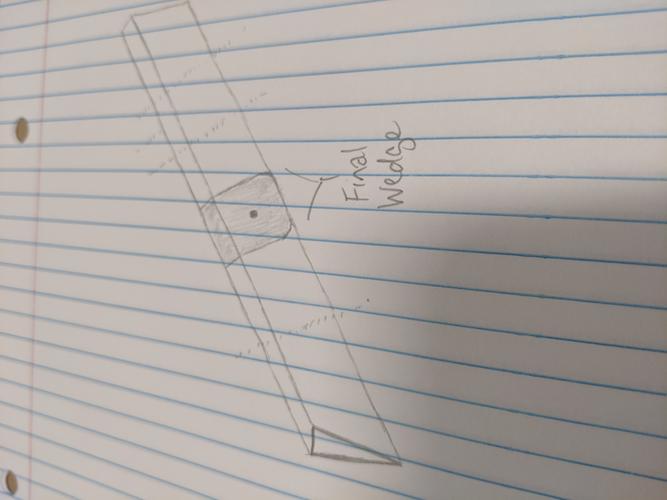

Just a rough idea for making bars that can be cut up into desired sizes. You would only need two flat pieces of metal held at the desired angle to create the mold.

EDIT: Dang it. Took the photo portrait style and it STILL got flipped.- Joshua

-

05-25-2019, 03:56 PM #16344

FWW

using two form strips . . . (Now as above...)

Could be a good way to make a wider stick and cut off the needed lengths at the proper length...

BUT:

Make the width of the wedge from thin end to wide, wider than usually needed. Like making a wedge for thick blade. It has as to be wider than the usual, Then add extra beyond that.

OK, how often have you cut/ sanded a taper of material and after measuring cut the thick end to the blade width needed. and then cut the thin end off???

JMO

~RichardLast edited by Geezer; 05-25-2019 at 03:58 PM.

Be yourself; everyone else is already taken.

- Oscar Wilde

-

05-25-2019, 05:56 PM #16345

this is from a few years back but it is how i cast wedges with pewter. FWIW

-

The Following 3 Users Say Thank You to tintin For This Useful Post:

MikeT (05-25-2019), ScoutHikerDad (05-26-2019), sharptonn (05-25-2019)

-

05-26-2019, 03:00 AM #16346Senior Member

- Join Date

- Feb 2015

- Location

- Duluth, GA - Atlanta OTP North

- Posts

- 2,546

- Blog Entries

- 1

Thanked: 315

I haven't read all the posts, but if I the illustration I posted was something that had already been discussed it was unintentional. I just saw where someone mentioned making lead bars.

I found my punches! No one needs to lose sleep over it. - Joshua

- Joshua

-

05-27-2019, 01:30 AM #16347

So have any of you ordered from these guys at Gilmer Wood Company? https://www.gilmerwood.com/search/re...peghead+veneerTheir 1/8" guitar peghead veneers seem well-suited for razor scales. I'm thinking that I'm going to focus mostly on wood this summer, and am just scrounging for sources. I have already ordered from Bell Forest and Wood Turningz with great products and service.

There are many roads to sharp.

-

The Following User Says Thank You to ScoutHikerDad For This Useful Post:

JellyJar (05-27-2019)

-

05-27-2019, 03:32 AM #16348

I would try it out only if they could book-match a couple pieces for me. Being 4" wide on many of those, that would put you at not a bad price.

Of course, you will always get more bang for your buck if you buy a big piece of wood and cut it down, which is what I prefer.. But that's more money. Better deal, more money.

If you don't mind it not book-matched, and want to try out more varieties, then they look like a good one.

Though I haven't shopped around for a while, so I can't compare to other companies.

Have you been shopping around?

Good luck in your search, there are so many beautiful woods, each scale a unique work of art..“You must unlearn what you have learned.”

– Yoda

-

The Following User Says Thank You to MikeT For This Useful Post:

ScoutHikerDad (05-27-2019)

-

05-27-2019, 06:18 AM #16349

Looks like so nice pieces. Let us know if you order. Love those Rosewoods.

It's just Sharpening, right?

Jerry...

-

05-27-2019, 12:34 PM #16350

Thanks Mike and Jerry-I'll report back if I get any of their stuff. Jerry, I'm fixed for life on rosewood. I literally have planks of it from a trade years ago. I just have to cut it down. I'm more interested in Blackwood at the moment (which is also in the Dalbergia/rosewood family).

There are many roads to sharp.

91474Likes

91474Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote