Results 16,371 to 16,380 of 20575

Thread: What are you working on?

-

05-29-2019, 12:38 PM #16371

Here are a couple of new projects I picked up cheap... Or is that cheaply?

The Lady in Black on the bottom is a Kanners Blue Steel. It has significant hone wear especially toward the toe. Heavy X pattern honing I guess??? Nothing That can't be fixed. Still plenty of spine left.

Nothing That can't be fixed. Still plenty of spine left.

Anyway, the one I was really after was that beauty in the rough on the top.

It's a pre Wilson - Gorman Tariff Frederick Reynolds with very nicely colored opaque horn scales. That thing that looks like a crack up near the top pin appears to actually be grain in the horn but I'm still not sure yet. They have considerable warping and need some special attention. It appears there must have been some amount of shrinking. You see the badge in the middle of the scale there seems to have buckled towards the center in a couple of places. It can't have been very much though because there's plenty of room between the toe and the wedge.

I'm a little nervous about taking it apart for that reason but I'm also hesitant to try the boiling water since the wedge looks to be lead. That's probably not hot enough to melt the lead although it does have a very low melting point.

Can't wait to see that thing finished. I have a particular fondness for that shape of blade.Last edited by PaulFLUS; 05-29-2019 at 12:41 PM. Reason: Typo

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

05-29-2019, 01:29 PM #16372Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,455

Thanked: 4830

I don’t have a big hardware supply to buy from and my selection is limited locally, and everything else is mail order. Your typical ripping blade is a fat blade with large teeth and it will take a very wide kerf. If I’m ripping a ton of long boards that’s what I use. However if I am taking thin sliced off short block of expensive wood, I typically choose the bandsaw. If my son was visiting and broke my bandsaw blade for ripping and I had to use the table saw, then I would use a laminate floor blade, because the rake on the teeth is different, it has a thin kerf and makes a smooth cut. Make sure it’s very sharp, and go slow. That is my go to blade for messing with hard wood like yew or arbutus. A well set up bandsaw beats a table saw for making nice fine cuts.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

ScoutHikerDad (05-29-2019)

-

05-29-2019, 02:01 PM #16373Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,812

Thanked: 562

I think the setup for using a Japanese saw with a magnetic jig to cut scale blanks is simple and brilliantly low tech solution.

https://shavelibrary.com/w/Cutting_Scale_BlanksDavid

“Shared sorrow is lessened, shared joy is increased”

― Spider Robinson, Callahan's Crosstime Saloon

-

The Following 3 Users Say Thank You to DZEC For This Useful Post:

32t (05-29-2019), Geezer (05-29-2019), ScoutHikerDad (05-29-2019)

-

05-29-2019, 02:05 PM #16374Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,455

Thanked: 4830

If you have a great handsaw for ripping those jigs are awesome.

It's not what you know, it's who you take fishing!

-

05-29-2019, 05:04 PM #16375

What wood working I do is with friends who have a lot more experience than I do. So this is just something that I found.

https://www.amazon.com/Micro-Kerf40-.../dp/B00J8UM7CW

The reviews look great.Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following User Says Thank You to cudarunner For This Useful Post:

ScoutHikerDad (05-29-2019)

-

05-29-2019, 05:48 PM #16376

Shaved with the Timor today. Despite the small amount of pitting at the edge, it delivered a surprisingly smooth shave. Whether that edge lasts too long is yet to be seen.

-

05-29-2019, 10:06 PM #16377

-

05-31-2019, 01:17 AM #16378

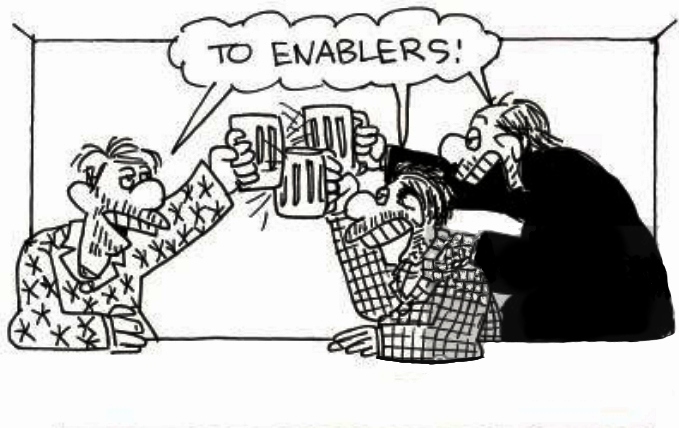

My friend, what are enablers for if not to 'Help' their friends?

If you do go with it. I would presume that you'd make a new piece that surrounds your blade out of wood or plastic, then while the table saw is running slowly raise the blade to provide a zero clearance so your slices wouldn't tend to slip down and get chewed up.

My wood shop instructor 'Grit' didn't like us cutting pieces that were up against the fence due to what he called 'The Arrow Effect' in that once the piece was cut the spinning blade would catch the piece and it would bind against the fence and be flung backwards. However Grit did say that if you knew it was coming it could be done.

When Ski has helped me cut 1/8" blanks we did the arrow set up. But Ski used a piece of wood against the guide so that it would push the blank past the saw and any 'arrow' was just a short end grain piece.

So as always--Safety First!

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following User Says Thank You to cudarunner For This Useful Post:

ScoutHikerDad (05-31-2019)

-

05-31-2019, 09:03 AM #16379

Thanks much as always, Roy! All of this may be moot at this point (though I still occasionally operate and still need every tip I can get on a table saw-that thing scares me a little TBH). I was talking to my knife-maker friend who stabilizes my wood yesterday. He has bought a fancy 14" re-cutting band saw with a 1-inch blade that will safely cut true, flat 1/8" blanks, which he says I can use any time I need it. This will save me many hours of flattening and thicknessing along with the choking clouds of toxic dust that generates. He is also cutting me some walnut burl into 1/8" blanks!

I'm going to have to gift that man a nice bottle of scotch, a fancy razor, something. If anyone is interested, here is his web-page (a bit dated, as I think he mostly posts on Facebook now, and I know he just finished a years-long contract for over 1000 fancy bowie knives (yeah, hard to believe, but true) for some outdoor outfitter whose name escapes me: Ross Tyser Custom KnivesThere are many roads to sharp.

-

05-31-2019, 01:05 PM #16380Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,455

Thanked: 4830

It is way more accurate and much faster to rip your blanks on a properly set up band saw than a table saw. You can cut a lot of wood in just a few minutes. You will likely spend more time sweeping up than sawing. His site may be dated but he has a lot of nice knives on there. Everyone is happy with a small token for sharing their toys. Depending on who it is some may be happier with baked goods than a bottle. To each their own I suppose.

It's not what you know, it's who you take fishing!

91478Likes

91478Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote