Results 15,341 to 15,350 of 20573

Thread: What are you working on?

-

01-31-2019, 08:56 PM #15341

-

The Following User Says Thank You to RezDog For This Useful Post:

jfk742 (02-01-2019)

-

01-31-2019, 10:56 PM #15342

-

01-31-2019, 11:18 PM #15343

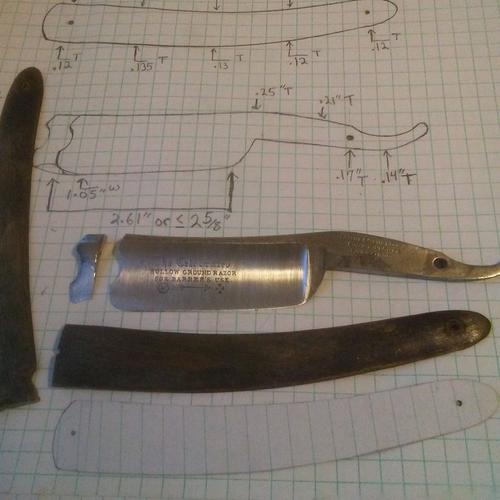

Alright! Got a little work done on this shorty..

Made a template of the original tip, marked it on with a sharpie, and cut it off with the dremel. Then put on the drum sandpaper grinding tip on the dremel (perfect size for the barber's notch!) and ground out the barber's notch.

Always paying close attention to the blade temp.. when in doubt, dunk it in water, it's easy to forget.

I still have a couple few hours of sanding on the back and need to clean up/straighten the groove pattern on the front.

The tip is not finished, but the heavy lifting has been done.

Then on to the scales which I already cut short, leaving a little extra length to work with.

She will have a shorter wedge, and the blade will fit a little closer to the wedge than original. Being a shorter blade, this will help the blade look a bit longer. Also I'm not into the Cadillac look.

I'll be making a new wedge (a sandwich), and save the original for a restore.

Sorry for the poor picture quality... cheap phone.“You must unlearn what you have learned.”

– Yoda

-

02-01-2019, 12:22 AM #15344Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,448

Thanked: 4829

That shorty is looking good. I am a little surprised that you did not breath a little life into this old thread https://sharprazorpalace.com/worksho...red-blade.html

It's not what you know, it's who you take fishing!

-

-

02-01-2019, 12:59 AM #15345

Very true, I should have. Perhaps it's not too late, there's more work to be done!

I have to admit that even though I agree that necroposting is a good thing, I've got an aversion to doing so. Well at least that's what I'm coming to know now.

This W&B shorty is just the first of a long line of butchered blades needing serious help.

This talk of threads is making me think of another relative thread..

https://sharprazorpalace.com/worksho...ml#post1521102“You must unlearn what you have learned.”

– Yoda

-

02-01-2019, 01:31 AM #15346

Back to square 1 on my scales. Seems the wedge is Silver-soldered to one scale.

Tried some propane-torch and twisting. Nothing doing! Going to leave it alone.

Polishing-up the insides and will do some light, fine sanding before polishing the tops to get scratches out as best possible. May just go with the Rodgers wedge if nothing else surfaces around here.

-

02-03-2019, 03:54 PM #15347

Old frenchies, «Saule à Condom». A well-preserved pair

First one is ready to be back on business, second one is warming up !

-

02-03-2019, 09:39 PM #15348

-

02-03-2019, 10:03 PM #15349

It’s rond-carved in the horn

-

02-03-2019, 11:19 PM #15350

I attempted to try and make a box for my Thuri. Figured I practice with a chunk of standard 2X4 cut to the right length. Drilled out the center of the section the hone would sit in then went with a chisle to take out the corners. CRACK! Well, it was an idea.

Guessing I'm too ham-fisted for detail work on a piece of pine. I could go out and buy some hardwood, but I'm afraid I might break it too. Then I'm out the cost of the wood and the time spent. I do OK with a hammer and nail but the chisles is not my friend and never has been.

I guess I could go buy one of those computer controlled lasers thingys and take a class on how to do it.

So, for now, my stone won't be resting in a nice wood box. Maybe I will run across one someday. HAH.

Time to sit down and do some honing.It's just Sharpening, right?

Jerry...

91473Likes

91473Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote