Results 4,241 to 4,250 of 20573

Thread: What are you working on?

-

08-14-2016, 06:33 PM #4241

Glued wedge, yet to ajust

-

The Following 4 Users Say Thank You to Thaeris For This Useful Post:

dinnermint (08-15-2016), engine46 (08-16-2016), sharptonn (08-16-2016), xiaotuzi (08-15-2016)

-

08-15-2016, 08:01 PM #4242

Made progress on the Hargreaves, Smith & Co. restoration. Here I have the brass wedge ready to be shaped, I made brass collars from tubing using a jig, shaped and polished the horn scales by hand, and hand sanded the blade to 2000 grit (dry) in preparation of putting a satin finish on it...

Later I went back and added the satin finish and polished the spine and tang...

-

The Following 10 Users Say Thank You to xiaotuzi For This Useful Post:

dinnermint (08-15-2016), engine46 (08-16-2016), Geezer (08-15-2016), jmercer (08-15-2016), Martin103 (08-15-2016), Mrchick (08-15-2016), Phil129 (08-15-2016), sharptonn (08-16-2016), Thaeris (08-15-2016), ultrasoundguy2003 (08-16-2016)

-

08-15-2016, 08:59 PM #4243

-

08-15-2016, 09:16 PM #4244Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

That satin finish makes the blade time correct in my opinion, well done.

-

The Following User Says Thank You to Martin103 For This Useful Post:

xiaotuzi (08-15-2016)

-

08-15-2016, 09:24 PM #4245

I basically followed advice from this thread http://straightrazorpalace.com/works...in-finish.html

After reaching a good smooth reflection at 2000 grit I worked backward, dry, 1500, 1000, 800 one direction carefully with a small leather backer. Once to 800 I gave a couple firm passes dry, then follow with a couple lightly oiled 800 grit passes. After that I jumped back up to 2000 oiled to soften and glow. I often have to redo when doing this because it's easy to get some lines crooked.

-

-

08-16-2016, 01:57 AM #4246

Hat's off. Splendid outcome!

-

The Following User Says Thank You to sharptonn For This Useful Post:

xiaotuzi (08-16-2016)

-

08-16-2016, 04:11 AM #4247

I got a couple more Felt Pads for a good price since each had a broken scale (2 separate auctions). I had the one already with a broken scale & then one popped up with the opposite scale broken so I made an offer & they accepted. The pin holding the felt in closest the pivot acts as a third pin also. I discovered that when I realized the wedges are shaped differently to accommodate for the felt but forgot to mention it on Show & Tell. I took 'em apart & it looks like the pin holes match perfectly. If it is off any, I'll just block the hole up & re-drill it.

This pic shows how they cut the scale out for the felt.

One blade says Felt Pad on the front side & the other says Twinplex like the DE razor strops. I think I had seen their name on some conventional strops before but I don't think I ever saw a Twinplex razor.

Stay tuned........

BTW, great work Thaeris, mercer, Outback & xiaotuzi!

Last edited by engine46; 08-16-2016 at 04:20 AM.

-

The Following 7 Users Say Thank You to engine46 For This Useful Post:

dinnermint (08-16-2016), Geezer (08-17-2016), jmercer (08-16-2016), Leatherstockiings (08-16-2016), outback (08-16-2016), sharptonn (08-16-2016), xiaotuzi (08-16-2016)

-

08-16-2016, 04:04 PM #4248Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

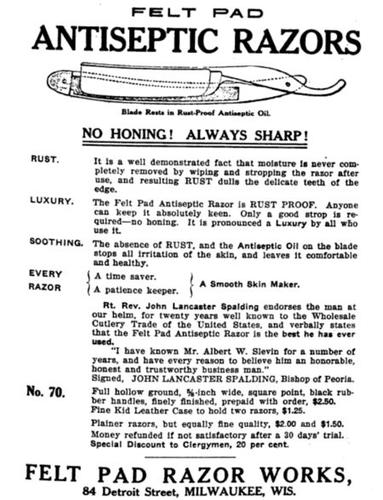

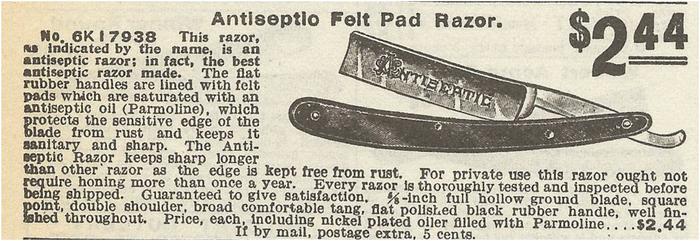

Felt pad razor, very interesting concept,patented in 1905, antiseptic oil or parmoline soaked pads to keep the razor clean etc. Wonder if their claim really worked.

-

-

08-16-2016, 04:38 PM #4249

Huh, I wonder where I can find a nickel plated oiler filled with Parmoline. What is Parmoline, by the way?

Thanks for the ads Martin103!

-

08-16-2016, 04:57 PM #4250Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

-

The Following 3 Users Say Thank You to Martin103 For This Useful Post:

jmercer (08-16-2016), Leatherstockiings (08-16-2016), MikeB52 (08-16-2016)

91473Likes

91473Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote