Results 5,101 to 5,110 of 20602

Thread: What are you working on?

-

10-08-2016, 01:51 AM #5101

Maybe this one?

16 in. Variable Speed Scroll SawOur house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

10-08-2016, 01:57 AM #5102

That's the one cudarunner.

B.J.

-

10-08-2016, 02:01 AM #5103

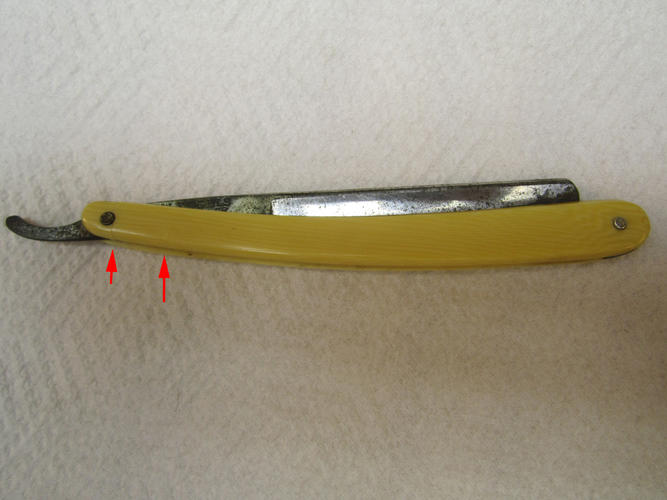

I've got an Engels Wedge here which came to me with a couple cracks right through the back side scale, really close to the pivot and the scales are pretty brittle. I believe it's a not-so-common razor from the limited research I've done so instead of replacing the scales I'm trying to save the originals. There's another one shown in this thread but with slightly different scales http://straightrazorpalace.com/razor...els-wedge.html Here's the one I'm working on...

I superglued it back together to hold the shape, then I'm attempting to reinforce by dishing it out a little on the inside and epoxying a piece of acrylic in there. After the epoxy sets I will sand the acrylic flush and redrill the pivot hole.

I thought about the possibility of making new scales and doing an inlay transfer but the inlay is anchored all the way through to the inside surface so not sure how that would work. Anyway, I'll clean up the blade a little later on after I get a better sense of what the outcome of the scales situation will be. Right now I'm feeling about 50/50 that this will actually work "Go easy"

"Go easy"

-

The Following User Says Thank You to xiaotuzi For This Useful Post:

sharptonn (10-08-2016)

-

10-08-2016, 02:59 AM #5104

If it don't work, Tuzi, send me the front scale and I may have a back one.

Perhaps it is just me, but they look like 2 different scales?Last edited by sharptonn; 10-08-2016 at 03:04 AM.

-

The Following User Says Thank You to sharptonn For This Useful Post:

xiaotuzi (10-08-2016)

-

10-08-2016, 03:01 AM #5105Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

As always I struggle with keeping my stuff organized. Some things I drag back and forth to work with me. This evening I'm trying to get some carving stuff organized.

part one. I also have a case that many plastic tubs fit into. Hopefully it can be organized tonight.It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

xiaotuzi (10-08-2016)

-

10-08-2016, 03:03 AM #5106

Should work for ya.

I did a similar repair on a set of celluloid scales that were broke in half.

Same way, dished it out, but used a piece of toothpick, split in half.

Epoxied the toothpick inside, and touched up the outside with CA.

(CA sands and polishes up better).

I used the T88 structural epoxy.Mike

-

The Following User Says Thank You to outback For This Useful Post:

xiaotuzi (10-08-2016)

-

10-08-2016, 03:08 AM #5107

-

10-08-2016, 03:11 AM #5108

As the saying goes...

There's an ass for every seat.

Should fetch a hefty sum too.[emoji23]Mike

-

10-08-2016, 03:12 AM #5109

They do look nice.

-

The Following User Says Thank You to Hirlau For This Useful Post:

outback (10-08-2016)

-

10-08-2016, 03:23 AM #5110

I'd always heard, you can't repair celluloid, Its a NOS no name, and had to give it a try.

Wanted to keep it all original, if possible. Figure the scales were broke from day one, and why it had never been honed.

Its got a itsy bitsy, teeny weeny bevel too, and shaves a real treat. But this is about Tuzi's razor, and don't want to hijack the thread.

Let us know how it works out for ya buddy.Mike

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote