Results 611 to 620 of 20573

Thread: What are you working on?

-

10-09-2014, 08:32 AM #611

Fascinating knife! It looks like a switchblade or side opening automatic. It is difficult for me to imagine the Jets or the Sharks taking time out of a gang fight to open a bottle of wine....I can imagine them cutting some cheese though...Sorry if this is some obscure Americana. So I had to use the Google to learn a little more about this style of knife. In doing so I found a French company who does some reproductions..definitely not nearly as cool as an original 19th century blade, but the work appears to be excellent: Atelier Graveline, coutellerie fine. QUOTE=Thaeris;1402567]1850 Châtellerault knife :

The same as the one of the left :

Currently :

[/QUOTE]

"Call me Ishmael"

[/QUOTE]

"Call me Ishmael"

CUTS LANE WOOL HAIR LIKE A Saus-AGE!

-

The Following User Says Thank You to WW243 For This Useful Post:

Thaeris (10-09-2014)

-

10-09-2014, 08:59 AM #612

The switch-automatic blades were designed after those knives.

L'Atelier Graveline is making wonderful knives ! They are not vintage, but seems to me of over the top quality.

The Châtellerault Queue de poisson::Atelier Graveline, coutellerie fine.

The Châtellerault Louvetier::Atelier Graveline, coutellerie fine.

Here are some wonderful restorations of vintage french knives :

Les couteaux restaur?s

From an apparently very talented french cutler (he doesn't restore anymore, but is still making beautiful knives)

Les couteaux du XVIII si?cle

Another one :

Coutellerie Nuage, Alex Dubois, artisan d'art coutelier

Coutellerie Nuage, Alex Dubois, artisan d'art coutelier

Last edited by Thaeris; 10-09-2014 at 09:07 AM.

-

-

10-12-2014, 08:50 PM #613

Recently completed this if you haven't seen it, so technically not working on anything at the moment.

I did however post about the scales and polishing when I was working on it earlier in the thread. Thanks for looking.

Joe

http://straightrazorpalace.com/custo...en-leaves.html

-

10-15-2014, 05:11 PM #614

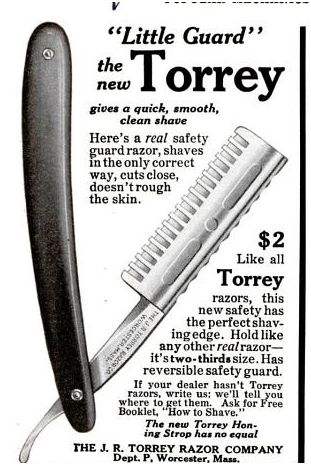

Got my Little Guard in the mail and figured I would give it an initial cleaning to see what I am working with. I am quite excited about this one because I have been wanting a shorty for awhile now and now I don't have to decide which of my razors I need to cut down. This one is already short. It is 2.25 inches from point to farthest part of the heel with an edge just over 2 inches. Just what I was looking for. Came with some black bakelite scales and seemed alittle long to me so I decided to use a set of small horn scales that snapped at the pin that have been sitting here since they are too small for anything else. Glad I decided to keep them. I placed it next to a 11/16 so show the size. 1st photo of when I got it and 2nd is initial clean up to remove the surface rust. Shouldn't turn out to bad.

-

10-15-2014, 05:42 PM #615

Any chance your shorty at one time was a frameback? I recall seeing something similar. I have a W&B frameback that I'm working on for a donation to the agricultural museum back home.

Just wondering? Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

10-15-2014, 05:52 PM #616

No they originally had a guard on them like some of the other safety razors. When I did a search for it almost all the photos I've seen were missing the guard. I am thinking they were probably just thrown out because they seem to be more hassle than anything. Here is a ad for one.

-

The Following User Says Thank You to JSmith1983 For This Useful Post:

Geezer (10-15-2014)

-

10-23-2014, 05:06 PM #617

I done did it.

I done did it.

On 10-3 I posted that I would make my first attempt at scales. Finally finished my attempt.

Know first that I have very limited shop skills. Rudimentary at best. Not an apology, a fact. I used the old scales as my pattern, except for the wedge end. There I tried to emulate the barber's notch of the razor. I lined the scales with high tech black plastic for no other reason than I wanted contrast to the bone. I did sneak into my son's shop (he's a general contractor with every tool and skill to use them) and did cut the scales shape out on a bandsaw. Tried first with a scroll saw and that was crap to do. Hand drilled the pinholes and that was an aching hand trip. I was not trying for perfection on this set of scales, just wanted to see if I could make them. Did some basic sanding, mainly rounding the edges and a little on the face of the scales. It ended up looking a little rough and I'm okay with that. Super finished was not the objective.

The blade is a 13/16 W&B Frameback. Had a fair amount of black rust on it. Work like a junkyard dog and got most of it off. Some sanding and left it kind of a matte finish. Again, perfection was not the aim.

And the pinning was the most "joy" a man can have, he said sarcastically. Re did the pinning twice to get to where they are functional and half way decent looking. When I did the pivot hole pinning I added a washer to the inside on one side of the blade and two washers on the other blade side to compensate for a slightly warped Camel bone. Now opens and closes cleanly. The wedge is a piece of fairly dense platic that i could cut with an X-acto knife.

What I have learned, failures and successes throughout, is that I can make scales and that shop skills increase, as with anything, with practice and execution. Curious to see my next effort.

Below are photos with all the warts and whistles for your perusal. Criticism politely accepted by this overtly adolescent octogenarian. Can't wait to hone it and see how it shaves.

"The sharpening stones from time to time provide officers with gasoline."

"The sharpening stones from time to time provide officers with gasoline."

-

10-23-2014, 05:50 PM #618

Eventually, I'll be following in your footsteps, making my first set of scales. If mine look as good as yours, I'll be happy.

Question: what was the problem with the scroll saw? After watching Undream's video in which he restores a razor from start to finish, I bought a scroll saw (still unused) rather than a band saw. In the video, he uses a band saw but says that if he had it to do again, he'd get a scroll saw instead.

Joe

-

10-23-2014, 06:01 PM #619

carrolljc, My mistake. Not a scroll saw, a hand held jewelers saw. The small 'U' shaped type. Like I said rudimentary shop skills. The jeweler's saw was to flimsy to cut the Camel bone, which I think is denser that wood. If my son had a scroll saw I would have used that.

"The sharpening stones from time to time provide officers with gasoline."

-

10-23-2014, 06:03 PM #620Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

Most shop tools are made for a certain use,Scrollsaws are made to cut very thin materials when doing scrollwork or fretwork,fine work in tight corners,Scrollsaw will work for making scales,so will a hacksaw.

A bandsaw,IMO is the proper tool for making scales.

If your making scales on a limited basis, use the scrollsaw,should serve you well.CAUTION

Dangerous within 1 Mile

-

The Following User Says Thank You to pixelfixed For This Useful Post:

carrolljc (10-23-2014)

91474Likes

91474Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote