Results 4,391 to 4,400 of 4688

Thread: The Butchered Blade

-

08-18-2016, 01:20 AM #4391

Good approach to the oldies, outback! Fast and easy to do the back-slash on the bottom stabilizer and be done with it!

Brilliant!

Saves steel too, I expect!

-

The Following User Says Thank You to sharptonn For This Useful Post:

outback (08-18-2016)

-

08-18-2016, 01:26 AM #4392

-

08-18-2016, 01:32 AM #4393

-

08-18-2016, 01:33 AM #4394

Really like the way these turned out, nice work. The Hess is calling me! You must have reshaped the toe a little because it blends nicely, looks natural. Good on the stabilizer too. I'm beginning to see broken blades in a different light - some can be shorties one direction, some can be shorties the other way!

-

The Following User Says Thank You to xiaotuzi For This Useful Post:

outback (08-18-2016)

-

08-18-2016, 01:47 AM #4395

Yes I reshaped the toe. Or it would have looked like a meat cleaver of some sort.

But only from mid toe to edge.

Mike

Mike

-

-

08-18-2016, 08:21 AM #4396

Nice job Mike. I have something to send ya with the nickel rod & collars.

-

The Following User Says Thank You to engine46 For This Useful Post:

outback (08-18-2016)

-

08-19-2016, 03:54 AM #4397

Finished up cleaning the Boker.

Did some hand sanding w/600&1000, removing most of the pits & patina, then gave the blade a satin finish to help hide some of the uglies, and highlight the etch.

No buffing for this one boys...as is, it is.Mike

-

08-19-2016, 12:04 PM #4398

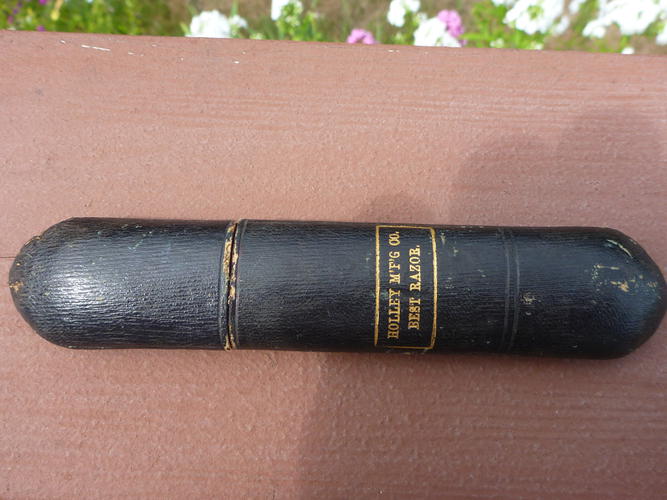

I'm not sure if this qualifies as a butchered blade but it was the worst pitted blade in my restore box. Started as a 7/8 and ended at .850. The pitting along the bevel was terrible. There was even a small frown near the toe that may have been the result of corrosion. Seemed an odd place for a frown. I wanted to see just what I could clean up on my grinder. The makers stamp was a bit light and uneven so I was forced to leave some pitting. The bevel came out small and even. I'm progressing along the learning curve with the grinder. Some before pictures, a couple after 600 grit and the finished blade in black horn. I have a few Holley razors but this is the first coffin I have found.

-

-

08-19-2016, 12:07 PM #4399

Lookin good Karl, haven't got into grinding yet, still all by hand...phew!

Mike

-

08-19-2016, 01:19 PM #4400Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,396

- Blog Entries

- 1

Thanked: 4200

Nice work Karl! that blade only qualifies due to the before picture. There's nothing butchered about that result sir. Very fine grinding evenness achieved.

Well done! "Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

13682Likes

13682Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote