Results 81 to 90 of 92

-

04-28-2018, 02:32 AM #81Senior Member

- Join Date

- Oct 2010

- Posts

- 26,211

Thanked: 8626

I would happily give you one I have, Zak.

The shipping would eat it up. Cast-iron!

Might be worth it?Last edited by sharptonn; 04-28-2018 at 02:36 AM.

-

The Following User Says Thank You to sharptonn For This Useful Post:

Voidmonster (04-28-2018)

-

04-28-2018, 02:36 AM #82

I'll just drive on over to pick it up.

Seriously though, if I can avoid getting one, I'll be happier. My tiny workshop is a little overstuffed as it is, and this whole resin casting experiment has taken over the dining room (which is the one room I can easily temperature control with a space heater).-Zak Jarvis. Writer. Artist. Bon vivant.

-

04-28-2018, 02:37 PM #83Senior Member

- Join Date

- Feb 2007

- Posts

- 392

Thanked: 105

Might look into this?

Aristocrat Water Clear Polyester Casting Resin

Thought about doing this but never seem to find time to play.

V/R

Tim

-

04-28-2018, 03:19 PM #84Senior Member

- Join Date

- Oct 2010

- Posts

- 26,211

Thanked: 8626

-

04-28-2018, 06:17 PM #85

I've avoided the whole class of resins that fume things up while curing because I don't really have a place that is both climate controlled and ventilated, but that may well be where I end up going. I've got ideas for how to make a sort of fume hood and climate controlled space in my workshop, but it's one of those things where, if I don't have to go there, I'd rather not because of limited space.

That was my first thought! The research I've done suggests I need 60psi and it looks like pressure cookers are designed for 15psi, so I'm not sure I'd trust one that far over its pressure rating.-Zak Jarvis. Writer. Artist. Bon vivant.

-

04-28-2018, 08:11 PM #86

Preliminary tests with the Smooth-On epoxy makes me think I got it.

Having a couple of bum molds is handy, since it gives me scales to do destructive experiments on. In this case, I got impatient and demolded the two unusuable molds.

The scales were still a bit rubbery, but it just felt like they were going to harden up nicely. So I threw caution to the wind and stuck them and a pair of the previous resin in the toaster oven at 150 for an hour.

The Smooth-On scales, once cooled to room temperature, are the exact same hardness & flexibility of the original celluloid.

The previous resin, even after 4 days and cooking in the toaster oven, are unusably soft.

The new material is marginally workable at this stage of curing. It can be cut with a hobby knife and sanded, but I was unable to polish it back up to the freshly demolded luster.

Also noteworthy, with just a few moments of vigorous polishing with a microfiber cloth, the heat will make them quite flexible again. They seem to return to their original shape when they cool though. So that, and more dye (as the color is a bit weak in this batch) are the next tests before I sign off on this material, but I feel like this stuff can be made to work one way or another. (It might require pressure casting though)-Zak Jarvis. Writer. Artist. Bon vivant.

-

04-29-2018, 07:41 PM #87

Smooth-Onís Epoxacast 690 can probably be a winner for this project.

I still need to mix up a batch with more dye in it to be sure it works (the other expoxy cured closer to right the less dye it had in it), but these have more or less passed all my other tests.

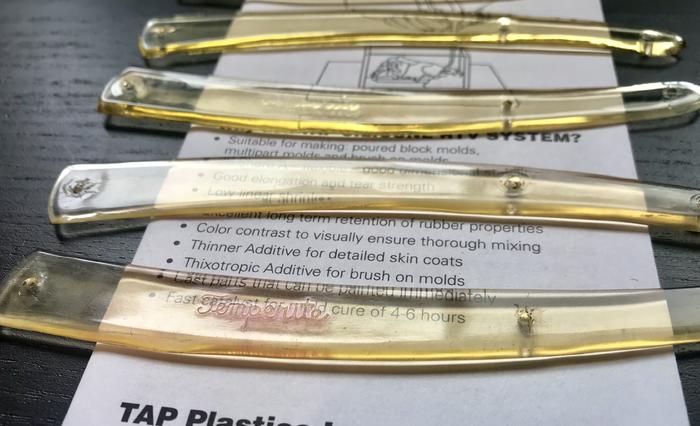

What does that mean? And what are we looking at in the pictures?

First of all, there are three different sets of scales from 3 diferent molds, one of which cannot cast complete scales because thereís a chunk missing from it. That means that scales from that defective mold are a little too thin an have a few odd distortions on the back side (or what would be inside on an assembled razor).

The scales from the incomplete mold are the ones I did the most experimenting with. I heated them in the toaster oven to speed their cure, Iíve painted the logo with the only paint I had available (pink nail polish from earlier etching experiments, which also meant I could test the material against acetone), and I sanded the living hell out of them then polished them on the buffer.

What I learned is at even near-full cure, this material is functionally workable. It isnít ideal by any stretch, but it can be sanded and repolished using micromesh and Motherís polish on a rag wheel.

In a strange twist, polishing them on the buffer is easier than doing it with a microfiber cloth, and the reason is:

With a 6Ē rag wheel on my buffer, the rotation of the wheel brings a lot of air through. With a very light touch, itís possible to polish the scales and keep them cool via convection, wheras polishing by hand the scales absorp all the friction energy and heat up.

If they go above about 115 degrees, they go rubbery, and if they get much hotter than that, they can be deformed. Itís really easy to bend them back into shape with gentle heat, but this is an important thing to know about.

When theyíre not being heated up, they feel almost exactly like the original celluloid.

One of the things thatís obvious from this round is that I need to make better molds, and that probably means largely completely recreating the originals scales instead of making a mold off them. All my copies look like perfect copies of slightly damaged scales, which is... uh... not exactly what I had in mind.

But I think Iíve got the materials part close enough. I can work with this stuff, and as long as folks know about the heat issue, I think things will be fine. I mean itís not like celluloid doesnít have the same problem!

Remember that pair of Shapleigh scales I sent you, Tom?-Zak Jarvis. Writer. Artist. Bon vivant.

-

The Following 3 Users Say Thank You to Voidmonster For This Useful Post:

cudarunner (04-29-2018), sharptonn (04-29-2018), tintin (04-30-2018)

-

04-29-2018, 07:50 PM #88

The heat thing seems a little low to me. If it could withstand a little more heat would be better but your very close. Ive been following along and your doing great with this. Congrads on getting this far. Soon you will have it all figured out and will be popping out scales left and right.

It's just Sharpening, right?

It's just Sharpening, right?

Jerry...

-

The Following User Says Thank You to Gasman For This Useful Post:

Voidmonster (04-30-2018)

-

04-29-2018, 11:30 PM #89Senior Member

- Join Date

- Oct 2010

- Posts

- 26,211

Thanked: 8626

Nice work, Zak! Way to stick with it!

You definitely have the mold thing going-on. They all look super!

-

The Following User Says Thank You to sharptonn For This Useful Post:

Voidmonster (04-30-2018)

-

04-30-2018, 04:11 AM #90

178Likes

178Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote