Results 41 to 50 of 98

Thread: An idea for a contact grinder.

-

03-12-2019, 12:38 AM #41Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,466

- Blog Entries

- 1

Thanked: 4207

Hey Zach, nice design work in fusion, and nice tools you are playing with.

Look forward to following your progress.

Blade making is on the to learn list. Like your drum grinder idea. Hoping fir some successes for you

"Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

The Following User Says Thank You to MikeB52 For This Useful Post:

Voidmonster (03-12-2019)

-

03-12-2019, 12:47 AM #42

That was a first for me, very cool!

Knowing that adds to the value of those little brass thingies we call collars. Not demystified in the least bit.

Thanks for the video, now... If you can just strap a go-pro to your forehead.. You can make your own channel!

Totally want to see more!“You must unlearn what you have learned.”

– Yoda

-

The Following User Says Thank You to MikeT For This Useful Post:

Voidmonster (03-12-2019)

-

03-12-2019, 12:56 AM #43

I've been watching a lot of This Old Tony videos.

So I've been thinking about good ways to shoot video of what I'm doing.-Zak Jarvis. Writer. Artist. Bon vivant.

-

The Following User Says Thank You to Voidmonster For This Useful Post:

MikeT (03-12-2019)

-

03-13-2019, 12:52 AM #44

Today I went SHOPPING!

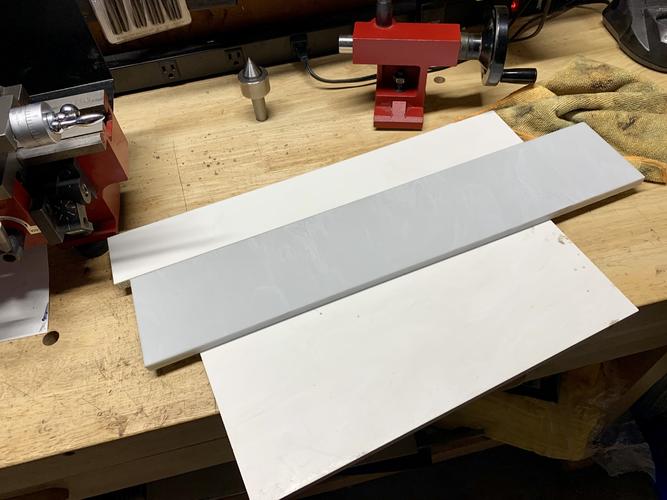

First up, as Richard foretold, a countertop service was happy to just give me cast offs of Corian. Now to take this stuff to the shop and mill it into shape for my jig/stiddy stick

Next up, I headed over to East Bay to check out Otto Frei, a jewelery supply warehouse with a neat little full-service front desk.

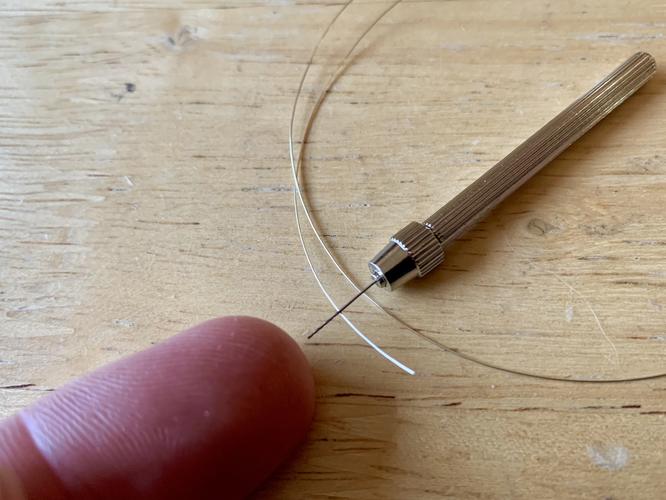

From there, I got some supplies to try my hand at doing pique work. This entails UNBELIEVABLY TINY DRILL BITS and a couple gauges of silver wire as well as some brass for contrast.

Also pictured: a new, very nice pair of flush cutters.

I bought the wire and the flush cutters and walked out the door. Just as I was about to get into the car I realized — not only do I have no drill bits small enough for this wire, even if I did, I don’t have anything I could chuck them in!

So back in for tiny twist drills and what’s labeled as a ‘baby pin vise’.

Pictured here next to the old razor handle I brought in to size this stuff off of.

No, really. It’s tiny!

I’ve got a variety of scale materials to try this stuff on from bone to a couple types of fake ivory. My suspicion is that bone is going to be the best bet, providing I seal it with CA glue so it doesn’t eat every morsel of dirt in my workshop, but a very preliminary test with the better of the fake ivories was surprisingly good.-Zak Jarvis. Writer. Artist. Bon vivant.

-

-

03-13-2019, 07:40 PM #45

Boy Zak, your really going all out on this! I look forward to some tips and tricks that you learn doing the pique work. Looks tedious.

-

The Following User Says Thank You to tintin For This Useful Post:

Voidmonster (03-13-2019)

-

03-13-2019, 10:23 PM #46

I figured I really ought to make the kind of razors I love -- I'd be more motivated to get them just right.

Oh god is pique work tedious.

The shop has a small CNC machine used for fabricating PCBs, I think I'm gonna see if it can drill holes for pins. That would take out the first tedious part, then it's just the inserting wire, cutting it, peening it, sanding it, swearing at it, and starting over again parts!-Zak Jarvis. Writer. Artist. Bon vivant.

-

-

03-14-2019, 02:17 AM #47

I better start saving money now because I know when you start selling these I am going to be in line!

What a curse be a dull razor; what a prideful comfort a sharp one

-

The Following User Says Thank You to Steel For This Useful Post:

Voidmonster (03-14-2019)

-

03-14-2019, 02:32 AM #48

I am sure he would take a $1,000 USD down payment without a guaranteed delivery date...

-

The Following User Says Thank You to 32t For This Useful Post:

Voidmonster (03-14-2019)

-

03-14-2019, 01:47 PM #49

-

The Following User Says Thank You to Steel For This Useful Post:

Voidmonster (03-14-2019)

-

03-14-2019, 09:13 PM #50

If I do pique scales, they ain't gonna be cheap.

I haven't had a chance to get to the shop and see if their PCB machine can do this -- I suspect #80 drill bits are too small for it -- but I have successfully gotten them to work on my drill press.

So far, printing the design (as 0.34mm wide dots), sticking that onto the work piece, and using my milling vise works reasonably well. The problem I have is that the fake ivory is a polyester resin and even at the lowest speed on my press it's fast enough that the holes melt a little, and so I have to then sand them flat and drill them a second time by hand before I can start putting the wire in.

Most of the designs seem to have between 40-200 pins. It took me about an hour to drill 30 or so holes the first time, and ... well, I needed to stop and eat lunch well before I finished cleaning out the holes again.

Bone will probably be easier in that I don't need to drill the holes a second time, but less easy in that I expect to break a lot more bits.-Zak Jarvis. Writer. Artist. Bon vivant.

318Likes

318Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote