Results 101 to 110 of 135

Thread: First brush

-

12-11-2016, 12:07 AM #101I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

Thought I'd add this, I think I've blabbed about it before. I've been reading about what other wood turners have been using for finishes, and focusing on what the true professionals are using. Hardwax oil keeps being mentioned as their top choice. In the near future I'll be giving it a go.

HardWax-Oil : woodchuckers.com

This is the Canadian site I've been getting my stabilizing fluid from, and they also have tons of other great products that are always tempting me.

For you American boys, I'm sure you should have no problem finding someone down there carrying these products.Burls, Girls, and all things that Swirl....

-

The Following User Says Thank You to HARRYWALLY For This Useful Post:

MikeB52 (12-11-2016)

-

12-11-2016, 12:21 AM #102Senior Member

- Join Date

- Dec 2013

- Location

- Virginia

- Posts

- 1,516

Thanked: 237

-

12-11-2016, 12:24 AM #103

Very interesting.

Thanks for the info, Im reading up on that stuff right meow.

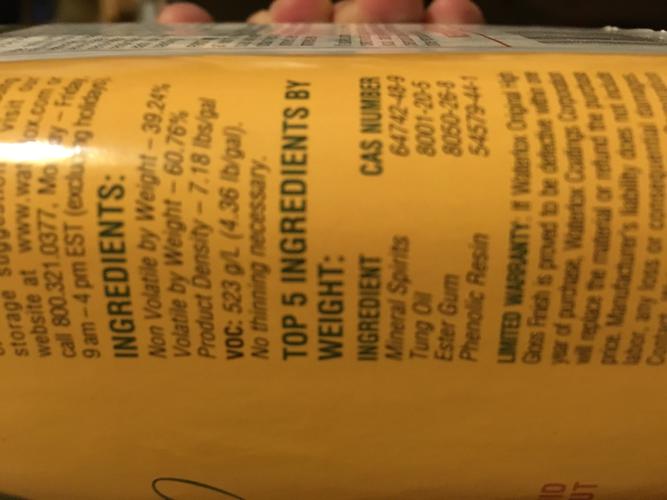

INGREDIENTS

Based on natural plant oils and waxes (sunflower oil, soya oil, thistle oil, carnauba wax and candelilla wax), paraffin, lead-free siccatives (drying agents) and water-repellent additives. Dearomatized white spirit (benzene-free).

Pretty cryptic, list of ingredients, thats whats in it...but what is in it hahaa water repellant additives...Im reading up some more, I want to compare it to my old favorite waterlox.

Oh the $%#@ing sideways pics are KILLING me!!

-

12-11-2016, 12:32 AM #104I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

Good question......

Rubber bumpers for your chuck would be the ideal way, but you probably don't have those. Even if you did, I'm not sure you could reverse chuck it to finish the bottom......

wrapping the base with masking tape comes to mind, but we still have the same problem with reverse chucking it to finish the bottom....

I've tried wrapping the badger hair with masking tape, and grabbing onto that, but it just doesn't work.....

If it were me, I'd hand sand all that crackle off and give it 7-8 spray coats of high gloss poly.

If that's not your flavor, sand it down and do a good oil like Tru Oil.

If none of that tickles your fancy, well, you might have to live with it.Burls, Girls, and all things that Swirl....

-

12-11-2016, 12:37 AM #105Senior Member

- Join Date

- Dec 2013

- Location

- Virginia

- Posts

- 1,516

Thanked: 237

-

12-11-2016, 12:40 AM #106Senior Member

- Join Date

- Dec 2013

- Location

- Virginia

- Posts

- 1,516

Thanked: 237

Valuable lesson I learned from this. Wait at least 48 hours after finishing a handle to install the knot, just to see how it reacts during curing. And don't use CA glue below 70 degrees Fahrenheit!

-

12-11-2016, 12:40 AM #107Who's that guy think he is...

- Join Date

- Jun 2011

- Location

- The North Coast, Ohio

- Posts

- 2,455

Thanked: 146

Another bonus to the parks epoxy is that there is no or very little smell, so you can do it in the house.

This brush is 4 years old and still shiney! A very durable finish.Luck is a matter of preparation meeting opportunity. ~Lucius Annaeus Seneca

-

12-11-2016, 12:43 AM #108I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

I hear yuh! and I agree with yuh!

At this point you have nothing to loose..... except that knot, and gives me a thought that I'll mention at the end.

That's actually a good idea Kyle and would be worth a try. Worse case if it doesn't work, you're still no further up shit creek and resort back to plan B.

Now back to my thought....

If worse comes to worse, you trim that handle down, get that knot outta there and start at square 1. Obviously a last resort, but that knot is worth far more than a buckeye burl handle. Just sayin.....Burls, Girls, and all things that Swirl....

-

12-11-2016, 12:44 AM #109

-

12-11-2016, 12:49 AM #110Senior Member

- Join Date

- Dec 2013

- Location

- Virginia

- Posts

- 1,516

Thanked: 237

The guy that teaches the bowl turning class I'm taking at woodcraft tomorrow is probably the most knowledgeable Turner I've ever seen. Granted I don't know that many, but he knows his stuff. Maybe I'll bring it with me to ask what he'd do. I'm thinking I can wrap the knot up pretty tight in plastic or paper then tape it. Possibly the knot will fit through the center of the chuck, allowing me access to both sides? In the future I think I'll save ca glue for pens. I'm going to try osmo polyx #3011 and see how that does.

236Likes

236Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote