Results 621 to 630 of 2504

Thread: 51 MG restoration.

-

12-15-2020, 10:22 PM #621Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

50mm didnít work. Corners were too rounded, shit.

So my 24 ď adjustable would grip to flats from the end. And my 3í Johnson bar does fit in between opened jaws, so how Jethro can I go.

About this far.

As Tom said, fine threads, left side is reversed, and not super tight, maybe 90 ft/lbs..

So now what? Do I pull the hub with a slide hammer or such or use a headlong puller to get the hub off?

This rear end is not originally out of the car so Iím working without a road map here.

Tom, and suggestions.

Looks like it should be just a bearing and rear seal holding this cap onto the rear axle now that the Jesus nuts are off. But before I start wailing with force, figured Iíd ask.

Cheers."Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

12-15-2020, 10:33 PM #622

I would use a log chain.

Now how will I describe this?

-

12-15-2020, 10:40 PM #623

looks like you need a puller that goes on the lug studs and an insert in the tube.

What's the rear end out of?

-

12-15-2020, 10:49 PM #624

Back when I was a youngster we'd put an old brake drum on backwards, put the lug nuts on backwards and run them down equally then push the brake drum flush with the axle and jerk the brake drum back forcefully to get the axle out.

I have used a 'Morgan Knocker' (Large Slide Hammer) with a hook on the end and put a chain across two studs, put some washers over the links, then use the knocker to bang the axles out.

https://www.morganmfg.com/ab_cat02.htm

Yea both are Brute Force and Ignorance methods Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following User Says Thank You to cudarunner For This Useful Post:

MikeB52 (12-15-2020)

-

12-15-2020, 10:51 PM #625Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

It’s out of an Austin Cambridge.

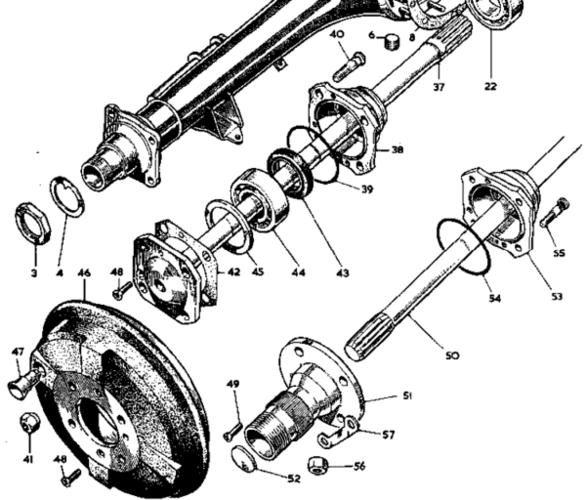

This is close, but different rear end image. Mine has the nut between 42 and 45. And the stub shaft in there over the whole shebang

Thinking a puller too with a plate fabbed up for the wheel spacing, just wasn’t sure."Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

12-15-2020, 11:17 PM #626

It might not be a press-fit. Try a pry bar on one side and tap on the other?

Slide hammer may work..

Or, one of these and the right sized one of those?

-

12-15-2020, 11:28 PM #627

Yeah, I'm thinking a little pressure and tapping. It may pop loose. Hell, A love tap and the bearings might jump out.

It's just Sharpening, right?

Jerry...

-

The Following User Says Thank You to Gasman For This Useful Post:

MikeB52 (12-16-2020)

-

12-15-2020, 11:34 PM #628

Do you have a crappy wheel? If not you could weld an X that would cover the bolts and put 4 holes to match the studs in it. Ideally put an eye bolt in the middle.

Heck!!!!!! As I am thinking of this I will change my mind.

Make one cross piece . Maybe an X if you are ambitious and then put it over the studs and use the lug nuts as a puller.

Back to my original idea if you put an eye bolt in the middle. then take a log chain to the eye bolt. If you leave the chain slack and then whip it up and down it would jerk it off.

I have done this by putting the hook of the chain in a hole of the wheel then snapping it. You may have to rotate holes.

Can be hard on the wheel but it works.

Tim

-

The Following User Says Thank You to 32t For This Useful Post:

MikeB52 (12-16-2020)

-

12-15-2020, 11:40 PM #629

I hope after seeing your picture I am thinking of jerking the right part off!

-

12-15-2020, 11:54 PM #630

This looks similar...

-

The Following User Says Thank You to sharptonn For This Useful Post:

MikeB52 (12-16-2020)

8857Likes

8857Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote