Results 61 to 70 of 106

-

05-24-2013, 01:11 AM #61

Diligent problem solving .

Congrats.

Congrats.

If you can't solve the issue by lapping with the Atoma, the stone is faulty. If you read some old posts you will see the 'graininess' problem has occurred with other stones also. Notably the Norton 4/8 & also my 12k Shap Pro. It is usually just the top skin that needs to go but at least you have notified your supplier in case you need to claim warranty.The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

The Following User Says Thank You to onimaru55 For This Useful Post:

DDTech (05-24-2013)

-

05-24-2013, 06:22 AM #62Senior Member

- Join Date

- Feb 2008

- Location

- Taiwan

- Posts

- 226

Thanked: 44

Good diligent diagnosis and good accompanying pics. This thread ought to be a good reference for others in the future.

-

The Following User Says Thank You to Tierdaen For This Useful Post:

DDTech (05-24-2013)

-

05-24-2013, 09:53 AM #63Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

-

The Following User Says Thank You to Neil Miller For This Useful Post:

DDTech (05-24-2013)

-

05-24-2013, 12:05 PM #64Senior Member

- Join Date

- May 2013

- Location

- Berlin, Germany

- Posts

- 286

Thanked: 39

Thanks. Yes, sure, I tend to blame the stone - either this particular one or the construction in general. However, as one of the posters stated, with two misbehaving stones, chances are high the cause is the operator, not the operant.

If it's the stone that causes the contamination itself, I'd guess, the problem lays in the compound being unable to hold the particles.

-

05-24-2013, 12:17 PM #65

Have you set your Atoma up (you know, run some steel over it to get rid of high diamonds) and lapped the Naniwas yet?

Hur Svenska stålet biter kom låt oss pröfva på.

-

05-24-2013, 12:49 PM #66Senior Member

- Join Date

- May 2013

- Location

- Berlin, Germany

- Posts

- 286

Thanked: 39

I start getting used to going to bed with the birds tweeting and the Sun rising...

Yesterday I bought a 400 grit ATOMA Diamond plate.

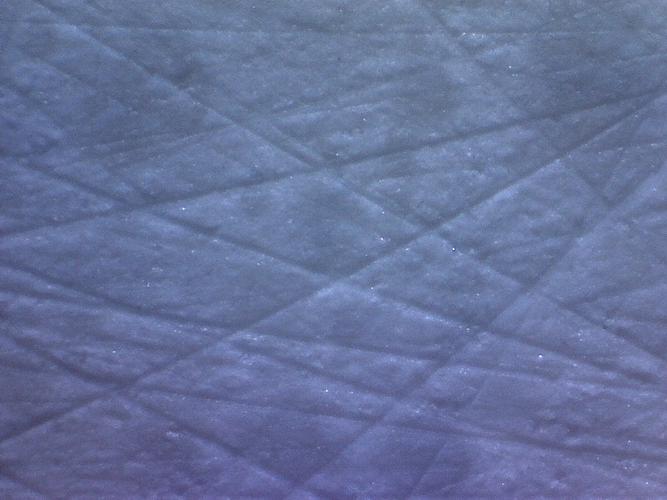

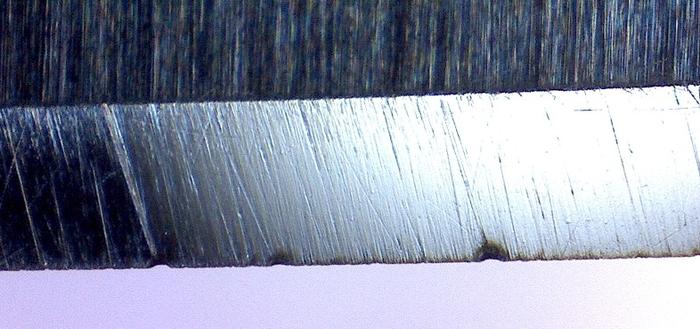

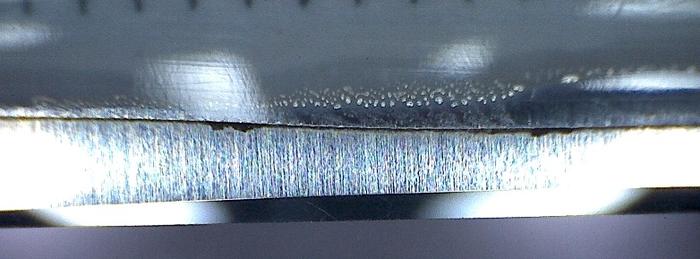

WOW, now that looks different.

If You compare this to the images of my previous post ("mountains peaking out of the mist"), the difference becomes even more apparent.

So... bevel set at 800, followed by 3k and 5k ... oops minor issue there ... maybe touched something. Not ready with 3k anyway ...

and try the 12k ....

Holy sh...

Granted though, that this now might be contamination from the diamond plate.

Felt free grain on the plate when I wiped over it with my fingers.

Who are You...?

Consecutive strokes then seemed to be OK. But what else could I do? How on earth could I make sure this does not happen?

For testing purposes, I did a shortcut here. In real life, I'd introduce myself to the 12k stone after some two three hours of working up the progression. And if by then I feel, I'm in the mood for gambling, I'd rather go into the casino than to play this shabby game.

In case someone is interested.

This is around 50 power

This is 20

desperatly

Yours Frank

-

05-24-2013, 12:57 PM #67Senior Member

- Join Date

- May 2013

- Location

- Berlin, Germany

- Posts

- 286

Thanked: 39

-

05-24-2013, 03:27 PM #68Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

I was really hoping that the Atoma would sort the problem out for you.

Maybe you should look at other things rather than the finishing hones.

As Onimaru pointed out, you shouldn't be using heavy pressure on the 8k hone - in my experience that is a sure way to get a burr/wire-edge or micro-chip the bevel due to its fragility at this stage and the fineness of the grit. If pressure is necessary, then I only use it at bevel-setting, on a 600 or 1k hone. The bits of foreign matter you have pictured look like the remnants of a wire-edge, particularly the ones that are a bit shiny. The darker bits could still be steel that has rusted and gone black or brown. Maybe the reason your 8k isn't affected is because you are taking the razor to the 10k/12k with the burr still on it?

You also mentioned how long it is taking you to hone the razor - that seems way too long to me, and usually represents the extra work that a problem blade gives rise to (eg one with a warp/kink in the spine). In any event, the 10k and 12k hones you have do not require an excessive amount of laps: personally I got best results around 20 - 30 laps, but some people say they do 50 - 60 (which would be excessive for me).

All your chips should be removed and the bevels set by the 1k mark. Then you just refine on the other hones. Just to make sure that there are no burr issues, you could try commencing with some half-laps on each stone (ie rubbing the blade - gently - up and down on one side, flipping it and doing the same on the other side) before proceeding conventionally.

Most people do not use a slurry (and I think the manufacturer says not to) with these stones, but I always have. Just a light slurry thinned with water - it helps to prevent a wire edge forming in the first place as well as speeding the work up a bit. On the last couple of hones I always thin down to plain water though. Been doing it for years and it has not hurt my superstones or choseras.

I'm not trying to teach you how to suck eggs, but you could give these things a try if you haven't already done so, just to rule another thing out.

BTW, although a DMT 600 is a sound hone for setting a bevel on, I don't think you will like the feel of the Atoma for bevel setting. The random nature of the diamond clusters on Atomas has a freaky feel to it to me on a razor.

Regards,

NeilLast edited by Neil Miller; 05-24-2013 at 03:30 PM.

-

05-24-2013, 03:35 PM #69

I was also thinking broken off wire edge.

You could try and strop it between the hones, I do it on my hand.

Suck eggs, how do you do that?

You do take some nice photos, what's your camera, USB microscope?Hur Svenska stålet biter kom låt oss pröfva på.

-

05-24-2013, 03:39 PM #70Senior Member

- Join Date

- Apr 2008

- Location

- Essex, UK

- Posts

- 3,816

Thanked: 3164

22Likes

22Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote