Results 11,451 to 11,460 of 20602

Thread: What are you working on?

-

11-03-2017, 04:27 AM #11451

It totally makes sense now. I put a straight edge across the blade face and it clicked. Thanks Tom and Shaun, much appreciated.

Nothing is fool proof, to a sufficiently talented fool...

-

11-03-2017, 11:19 AM #11452

Looking good, Eric. You're on your way now and probably have a sense of the time it will take to get where you want to. Doesn't seem so bad once you get a start on it. Funny about sanding your finger, I did the same to mine yesterday sanding a wedge for scales. Duh. Wasn't using a little jig, trying to just grip it on both ends.

Keep going, looking forward to seeing the progress!"Go easy"

-

11-03-2017, 12:05 PM #11453

Oh boy this will be an adventure for sure Tuzi. Now I have a grasp of what is actually going on it won't be so bad. Sad part is I have a like at least 3 more that will need this same treatment. But once you get going it's not too bad

great write up btw, I remember following it after re reading it.

Nothing is fool proof, to a sufficiently talented fool...

great write up btw, I remember following it after re reading it.

Nothing is fool proof, to a sufficiently talented fool...

-

11-03-2017, 12:12 PM #11454

Looking great there Eric

Watch them fingers, and now that you've got it figured out I'm loking forward to your successLook sharp and smell nice for the ladies.~~~Benz

Imperfection is beauty, madness is genius and it's better to be absolutely ridiculous than absolutely boring ― Marilyn Monroe

-

The Following User Says Thank You to Dieseld For This Useful Post:

ejmolitor37 (11-03-2017)

-

11-03-2017, 02:35 PM #11455

Another thing to mention....Stay light at the end of the blade. I always tend to get that too thin as the roll drops off, the tendency to have it tilt causes it. Keep the roll flat up there.

Looking forward to more advise from Tuzi as this progresses.

He knows how to do it correctly. Anything I do is like an accident.

-

The Following User Says Thank You to sharptonn For This Useful Post:

xiaotuzi (11-03-2017)

-

11-03-2017, 02:58 PM #11456

That's what I'm hoping for Tom, an accident that looks good

hopefully I got my accident out of the way last night with my finger tip. Out of all the monkey business with razors last night was the first actual cut from one. Good track record I guess.

Nothing is fool proof, to a sufficiently talented fool...

hopefully I got my accident out of the way last night with my finger tip. Out of all the monkey business with razors last night was the first actual cut from one. Good track record I guess.

Nothing is fool proof, to a sufficiently talented fool...

-

11-04-2017, 04:55 PM #11457

Nice work fellas, its been a few days since I've looked in on the thread, found I was quite a few pages behind.!

Mike

-

11-04-2017, 05:03 PM #11458

I couldn't agree more Tuzi.

Yeah Eric, a Dremel is limited with what you can do with one so I agree with you & Tuzi. I have used mine for polishing sometimes, shortening a blade or taking some of the edge off but as I have always mentioned, if used wrong, it can have a very unpleasant outcome plus injury may occur. When using one, ya gotta keep in mind which way the tool is rotating.Last edited by engine46; 11-04-2017 at 05:54 PM.

-

11-04-2017, 05:54 PM #11459

-

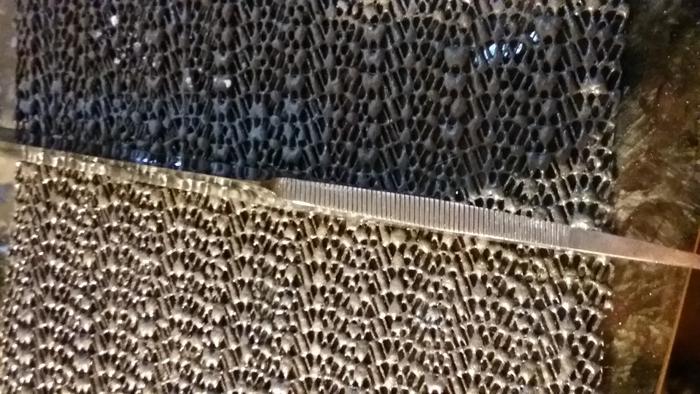

11-06-2017, 12:37 AM #11460

In between hand sanding my W&B wedge, I started working on my W&B FBO. There were some ugly scratches just above the bevel, sanded those mostly out didntdidn't want to work that area too much. Other than that used mothers and white scotchbrite. Been using the white scotchbrite and polish quite a bit, it cleans nicely, doesn't scratch and doesnt effect the original finish.

Nothing is fool proof, to a sufficiently talented fool...

Nothing is fool proof, to a sufficiently talented fool...

-

The Following User Says Thank You to ejmolitor37 For This Useful Post:

xiaotuzi (11-06-2017)

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote