Results 11,591 to 11,600 of 20573

Thread: What are you working on?

-

11-12-2017, 09:42 PM #11591

Finally got around to getting a chip out of my W&B. It took a while, had to go 1k, 4k, 8k then my coti.

But I'm so happy to have it back in use. I got it from Maggard's and Brad did the restoration on it.

It's my first W&B so it is pretty special to me.

Now just to be very very careful with it Look sharp and smell nice for the ladies.~~~Benz

Look sharp and smell nice for the ladies.~~~Benz

Imperfection is beauty, madness is genius and it's better to be absolutely ridiculous than absolutely boring ― Marilyn Monroe

-

11-13-2017, 01:15 AM #11592

I got the James Barlow & Sons finished. I posted some more pictures in another thread

B.J.

B.J.

-

-

11-13-2017, 01:20 AM #11593

Nice razor, BeJay - and a heck of a save. You managed to get the crack out and make the end look good at the same time! Congrats!

"Go easy"

-

The Following User Says Thank You to xiaotuzi For This Useful Post:

BeJay (11-13-2017)

-

11-13-2017, 02:51 AM #11594

-

The Following User Says Thank You to jmabuse For This Useful Post:

BeJay (11-13-2017)

-

11-13-2017, 04:46 AM #11595

My buddy had some replaceable cutter lathe tools that he could no longer find new cutters for. So I told him order new easy cutter bits and I'll re mill them to fit. So I have both the square and round cutter done.

I only have a pic of the round cutter. Extended the flat on the bottom for the tool rest and fit these new cutters. They were alot thinner and smaller as they are midi size. The minis would be super small!Nothing is fool proof, to a sufficiently talented fool...

-

11-13-2017, 02:21 PM #11596Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,455

- Blog Entries

- 1

Thanked: 4207

Welcome to the forum Luke.

There is a dedicated thread in the workshop for forge and blade work.

Might try to ask in there about specific grinding and finish techniques.

Wish I could help, but I'm a restore guy, not a bladesmith.

Good luck."Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

11-13-2017, 02:58 PM #11597

Yep, B52 gives good advise.

You have stumbled-upon the 'hammer and screwdriver' crowd down here. "Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

11-13-2017, 03:14 PM #11598

Luke, one of our administrators, Bruno, is a blade smith extrodiner.

He does have a website of his own that is pretty much dedicated to bladesmithing.

It's called Wet Shavers Workshop. You might want to check it out.

Wet Shavers Workshop

Cheers,

Pete <:-}"Life is short, Break the Rules. Forgive quickly, Kiss Slowly,

Love truly, Laugh uncontrollably, And never regret ANYTHING

That makes you smile." - Mark Twain

-

The Following User Says Thank You to petercp4e For This Useful Post:

32t (11-13-2017)

-

11-13-2017, 05:24 PM #11599

Here is where you want to post this. The Forge

-

The Following User Says Thank You to bluesman7 For This Useful Post:

sharptonn (11-13-2017)

-

11-14-2017, 03:33 AM #11600

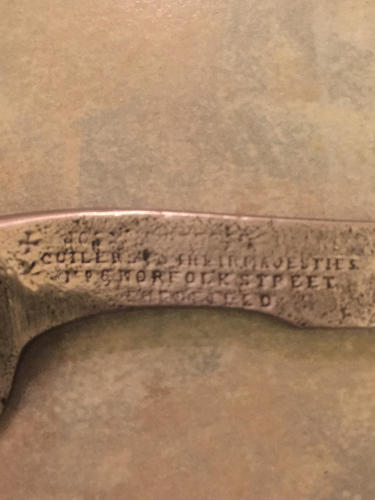

I'm trying my hand and a few fits of unbridled rage at restoring my first razor. I picked this up and it was labeled as a Joseph Rodgers C1870. The blade came as is in the first photo. Scaleless and afraid. I went at it with some 80 grit greaseless compound and was irked to find that there was an exorbatent amount of pitting underneath. I've been at it for nearly three hours now. I was experimenting to see how the metal behaved under light pressure, firm pressure, rolling movements, see saw, etc... I was trying to save the shoulder and stamp but when I cut away little by little with the 80 grit it was revealed to have been worn away before I got to it. I see now that the compound leaves everything "softer". The edges, profile, notch, and blade face looks to have much softer features. I don't think I mind. Wait, where am I?

Just remember.

Just remember.

Wherever you go,

There you are.

91474Likes

91474Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote