Results 14,221 to 14,230 of 20602

Thread: What are you working on?

-

10-02-2018, 11:00 AM #14221

I started on the last two razors, belonging to MrZ.

Blades only need a bit of cleaning at the pivots, its the scales that need attention.

Giving the scales for his Reynolds another day of drying, and will be pinned later thus eveningMike

-

The Following User Says Thank You to outback For This Useful Post:

MrZ (10-02-2018)

-

10-02-2018, 01:15 PM #14222Senior Member

- Join Date

- Sep 2017

- Location

- Upstate New York

- Posts

- 641

Thanked: 104

I am about to have three awesome razors! I would have tried to use CA glue to fill those bug bites, but I really liked those razors to much to mess them up, so off to Akron for a champion restorer to do it right. I will keep trying on junk blades, but Outback is the man. I cant wait to see them.

-

The Following User Says Thank You to MrZ For This Useful Post:

outback (10-02-2018)

-

10-03-2018, 01:04 AM #14223

Here are the scales from the Tally Ho that I'm working on.

I did a bit of sanding with 1500 grit wet/dry sandpaper, and they are cleaning up. However, the blacker of the halves has some gouges in it as seen in the 2nd pic. Should I just do my best to smooth that out with some lower grit paper and then work my way up again to the higher grit paper? I've got up to 3000 grit if needed.

Also, I think I've heard about soaking in oil at some point?

-

10-03-2018, 01:12 AM #14224

Yup. Try some scotchbrite. I love that on horn scales. Fine steel-wool. Blends things nicely, for me.

-

The Following User Says Thank You to sharptonn For This Useful Post:

sonnythehooligan (10-03-2018)

-

10-03-2018, 03:22 AM #14225

Depends on the finish you want. I typically go no lower than 400 grt., then 600, 0000 steel wool, for a grainy matte look. Or I'll go as high as 1500grt., and buff for a polished finish.

Mike

Mike

-

10-03-2018, 03:35 AM #14226

Made the repairs on MrZ's scales tonite, and was about to pin up the Reynolds when I remembered I still needed to make a wedge for it.

DAMMIT.!!

DAMMIT.!!

Im off work tomorrow, so I'll have it ready for an evening shave, after I hone it that is..

Mike

Mike

-

10-03-2018, 01:17 PM #14227Senior Member

- Join Date

- Sep 2017

- Location

- Upstate New York

- Posts

- 641

Thanked: 104

There is so much to learn from all of you guys. The quality of work that goes on around here is amazing.

-

The Following User Says Thank You to MrZ For This Useful Post:

outback (10-03-2018)

-

10-03-2018, 01:45 PM #14228

-

10-03-2018, 04:28 PM #14229

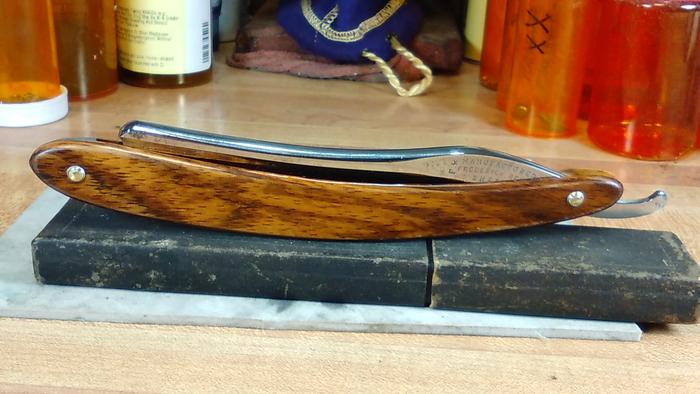

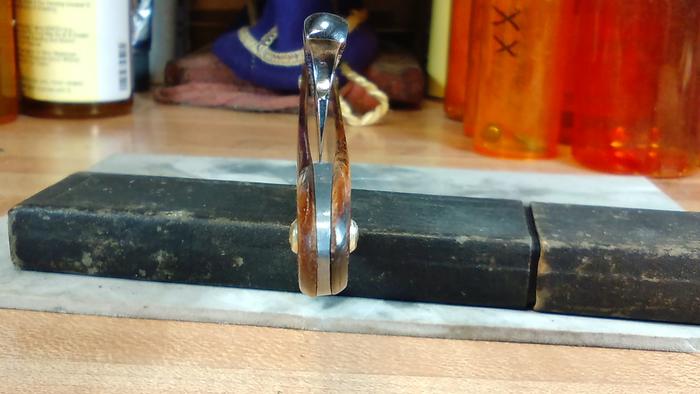

Finally..!!

I got the wedge made and fitted to the scales using mock up screws, and the help of a piece of paint stick to replicate the tang. Once the mass of the wedge has been removed from around the scales, I replace the paint stick with the actual blade, so I can shift the scales and center the blade without having to use shims on the tang, then snug it all down and do the final fitting on the wedge.

Then a quick dismantle, and pinned up with some of Austin's collars, and brass rod.

Ready for the hones.. Mike

Mike

-

-

10-04-2018, 11:01 AM #14230

I noticed a drilling error on this one. I was thinking that filling this in with epoxy might be the trick. Any better approach to this?

Also, if I buff these, is there a preferred buffing compound for this?

I have some pinning supplies on the way, so I'll be wrapping up this project soon.Last edited by sonnythehooligan; 10-04-2018 at 11:16 AM.

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote