Results 15,821 to 15,830 of 20573

Thread: What are you working on?

-

03-24-2019, 01:33 AM #15821

Lordy, lordy....

This!

-

03-24-2019, 01:51 AM #15822

-

03-24-2019, 02:08 AM #15823

-

03-24-2019, 05:39 AM #15824Senior Member

- Join Date

- Feb 2015

- Location

- Duluth, GA - Atlanta OTP North

- Posts

- 2,546

- Blog Entries

- 1

Thanked: 315

-

03-24-2019, 01:46 PM #15825

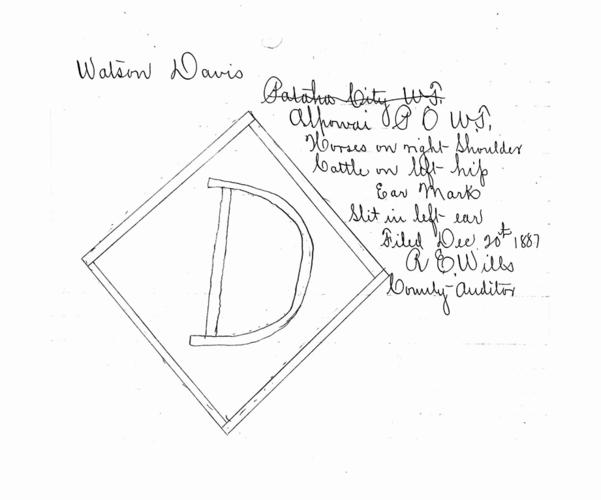

I was wondering how to in cowboy slang.

https://co.garfield.wa.us/museum/reading-brand

-

03-24-2019, 07:09 PM #15826Senior Member

- Join Date

- Feb 2015

- Location

- Duluth, GA - Atlanta OTP North

- Posts

- 2,546

- Blog Entries

- 1

Thanked: 315

Like a teeth whitening chart.

- Joshua

- Joshua

-

03-24-2019, 11:00 PM #15827

Still have a lot of material to remove to get to a point where I can start closing in on the size I need. Rough sanded with 60grit w/d, and as I get closer to size I need I will go up in grits. I also still have to crown the top to match the bolsters, again creeping in on the curve so I get a good fit on the bolsters. As far as removing them, it was pretty straight forward. Just clipped the ends off then put them in a glass with acetone. Going to very carefully polish the insides of the bolsters, as the scales are clear you will see the gunk through the scales I would think

Once I get them to size I need, lots of sanding through the grits prolly to 2000k or 2500k then polish to get a good clear, perfect finish. Then going to gently attach the bolsters. Thinking this should turn out decent.

-Laramie-"If the brakes don't stop it, something will"

-

The Following User Says Thank You to yondermountain91 For This Useful Post:

randydance062449 (03-25-2019)

-

03-24-2019, 11:35 PM #15828Senior Member

- Join Date

- Feb 2015

- Location

- Duluth, GA - Atlanta OTP North

- Posts

- 2,546

- Blog Entries

- 1

Thanked: 315

These bolster transplants are always interesting to see. A lot of care for them to turn out right.

If you find you want to go finer on the finish you can buy a set of small micromesh pads that go up to REALLY high grits.

Look forward to seeing this progress. Please take PLENTY of pictures. Maybe even start a WIP thread to document everything.- Joshua

-

03-25-2019, 06:37 PM #15829Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

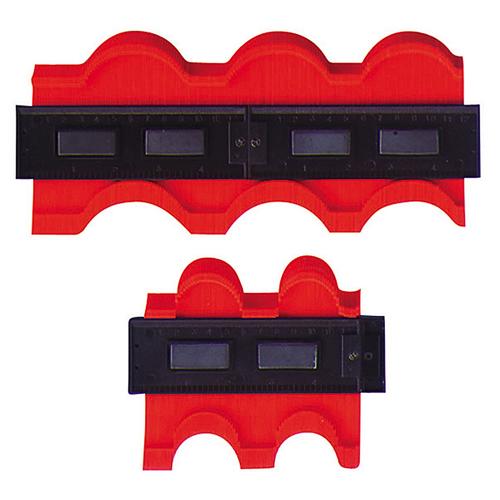

An inexpensive Contour Gage, ($5) will greatly save a lot of trial and error fitting in the early rough shaping stage.

Measure the contours from the inside of the bolster and the old scales, go slow in shaping, it is a tapered compound curve. Use your pin hole and back edge as reference points, those points will not change.

A dollar store, thin snap blade razor knife, used as a scraper can be easier and quicker removing material at targeted spots, as well as making sanding sticks from Coffee Stir &, Popsicle sticks, Tongue Depressors and Wood Paint stir stick in various grits.

You can buy replacement blades for a buck a pack or re-sharpened on a stone, or small paddle strop to keep a fine edge capable of removing thin shavings.

Once shaped, polishing goes quickly, just donít make deep scratches, once rough shaped, 400 & 600 finish shape quickly, 60 is aggressive and can make more work for you in the end and alter finished shape trying to remove.

Plastic and Celluloid polish easily from 1 and 2k.

-

The Following 2 Users Say Thank You to Euclid440 For This Useful Post:

cudarunner (03-26-2019), yondermountain91 (03-26-2019)

-

03-26-2019, 01:03 AM #15830

I switch up to like 220 before I get anywhere close to the final shape to avoid making them too small. Thanks for the reply mang going to start a new thread when I get around to organizing all the pictures. Just to keep everything in one place.

"If the brakes don't stop it, something will"

91474Likes

91474Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote