Results 16,061 to 16,070 of 20602

Thread: What are you working on?

-

04-22-2019, 03:27 PM #16061

Yep, I got mine from Tom, but that link is where they come from. They are big but easier to use for sure. I keep wanting to order up a couple more sets but haven't got around to it.

It's just Sharpening, right?

Jerry...

-

04-22-2019, 03:29 PM #16062Senior Member

- Join Date

- Oct 2010

- Posts

- 26,211

Thanked: 8626

Yeah, That is Sorin, the collar guy!

I tried them, they do work well. Esp if making scales, I would think.

I prefer the brass microfasteners nutsy-boltsies for the type of stuff I do.

I have about given away and worn mine out. Anyone have some to peddle?

-

04-22-2019, 03:46 PM #16063

Be happy to send ya a few Tom. Sending PM. The nuts and bolts that is. I have a few I can spare.

It's just Sharpening, right?

Jerry...

-

The Following User Says Thank You to Gasman For This Useful Post:

sharptonn (04-22-2019)

-

04-22-2019, 04:48 PM #16064

These are what I use & they're from Micro-Fasteners

Weird crap, I suddenly stopped receiving email notifications from the group for 2-3 months until suddenly this morning, I got one.Last edited by engine46; 04-22-2019 at 07:58 PM. Reason: forgot couple words

-

04-22-2019, 08:35 PM #16065

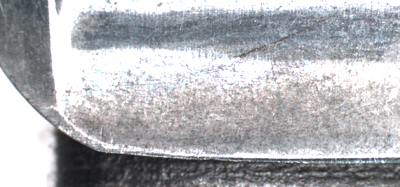

Here are the scales with the first coat of Tru-oil and the blade after removing and blending in the hone wear. One pic of the hone wear before I started. The other side was worse but I didn't think to get a shot of it...

A difference of 0.013 from toe to heal on the spine thickness. Not too bad. I've seen a lot worse with no hone wear.It's just Sharpening, right?

Jerry...

-

04-23-2019, 01:35 AM #16066

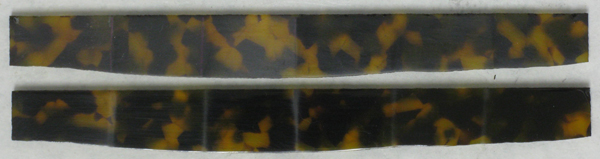

There seemed to be a little bit of interest in seeing a sanding/finish progression on the tortoise kirinite I'm working with for my Packwood. I decided to mask off areas of the leftover material and sanded the sections to 400, 600, 1000, 1500, 2000, and 2500. Then I hand polished one with simichrome followed by maas. I hope the different finishes are somewhat clear, the lighting was really messing with me. The differences are much clearer in the hand. My hope is this would help someone get an idea of what type of finish they want to go with if working with this material in the future, but the lighting/photography might limit it.

Top piece is without polish. Bottom piece is with polish. 400 on the left, 2500 on the right.

First pic is light through the 2500 end, second pic is light through the 400 end.

-

-

04-23-2019, 06:05 AM #16067

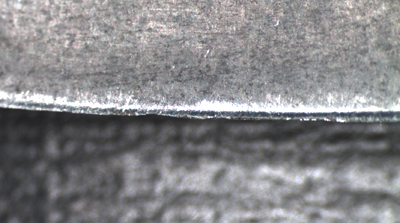

I had an hour before I could think about going to bed so I dug this razor out. Washington Cutlery Co. King of Whiskers. German blade, full hollow. Same shape as all my Imperials. I started on the face but then thought I'd better grab a couple of pics. Hone wear, rust, heavy patina, hooked stabilizer. I'm going to put it up for this week but I will need to unpin it to clean out the pivot area and get the gunk out of the inside of the scales. Should clean up but still have some battle scars, and end up as a decent shaver. It said King, so I had to have it. 12 bucks shipped on eBay.

This is after an hour working on the face, tang, and spine.

You can see the tail is still rusty.It's just Sharpening, right?

Jerry...

-

04-24-2019, 02:02 AM #16068

Lifted up the kilt on my Geneva...

Lifted up the kilt on my Geneva...

And found a few warts. The no re-pinning plan might be changing.

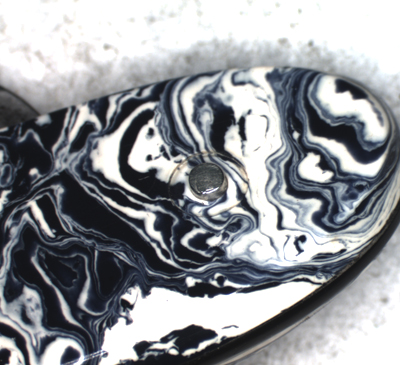

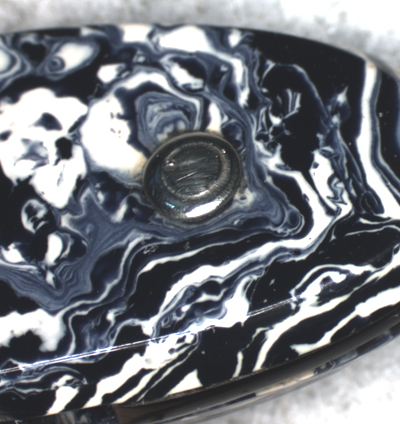

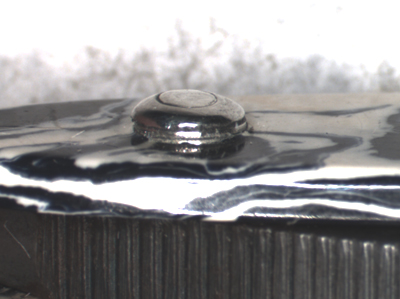

So I was doing a bit of light clean up on the Geneva I posted in Show and tell and noticed one of the collars was missing on the wedge end. I started looking closer and I'm not sure what kind of pins/collar set up this has. The opposite wedge pin has one collar that looks like it's part of the pin. One pivot pin is the same as the wedge pin with the collar and one looks like it has a washer and collar. On closer inspection today, there is a little space on the wedge side with the missing collar that I can close with finger pressure. Any info on this type of pin/collar set up. I think I need to at least re-pin the wedge and I really don't want to mess up the scales. Could I slip another collar over the pin and peen it down? Not sure how the collar even went missing. It definitely had one, you can see the dent in the scale. I also suspect there is a bit of rust on the tang around the pivot, combined with the different collar set up has me really considering a full disassemble and get the collars matching.

I also checked the edge with a microscope and noticed the heel end is rolled over, so it'll need a bevel re-do.

One additional little thing I noticed that shouldn't affect the performance, but I find a little interesting. Not sure how to describe this...the stabilizer grind on the right side, at the tang, extends out away from the tang and is chipped out. It's like the stabilizer didn't get finished all the way to the back of the blade.

Ok, I've got a bunch of pics I hope clear up some of my probably less than clear descriptions.

First is the missing collar, second is the remaining collar on the wedge, last is the washer/collar on one side of the pivot

Damaged edge at the heel (8X and 16X)

The missed grind area at the stabilizer

And in less razor related working on things, I've gotten to 1000 pages in this thread. I will catch up to this monster...

-

04-24-2019, 02:10 AM #16069

Nice! Looks like it's going to clean up really well.

What is the material on your razor holding block? Leather? I'm planning on making one and am deciding on materials. I've got some red oak left over from a shelving project and was trying to decide if I should leave it wood only or put some kind of pad/cover on the surface. Leather came to mind as I've got some of that left over from some other projects as well.

-

04-24-2019, 02:13 AM #16070Senior Member

- Join Date

- Mar 2015

- Location

- Indiana, Portland

- Posts

- 321

Thanked: 70

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote