Results 16,531 to 16,540 of 20573

Thread: What are you working on?

-

06-23-2019, 08:32 PM #16531Senior Member

- Join Date

- Feb 2015

- Location

- Duluth, GA - Atlanta OTP North

- Posts

- 2,546

- Blog Entries

- 1

Thanked: 315

Got a chance to do a little honing today! No fancy restoration projects going on, but it nice to do a little razor related work. Got a deal on some old DE razors I'm trying to clean up. Some are pretty rough, but maybe they is some shine under the crud!

- Joshua

-

06-24-2019, 09:55 PM #16532

Spent part of my rain day today fixing this broken Rodgers Refined Steel razor.

After carefully cutting off about 1/8" off the end of the blade, I honed it up and it's set for a shave test this week. I'll at some point descale it and do a proper cleaning and polishing on the blade and scales.

Last edited by Theseus; 06-24-2019 at 10:05 PM.

-

06-27-2019, 05:33 PM #16533

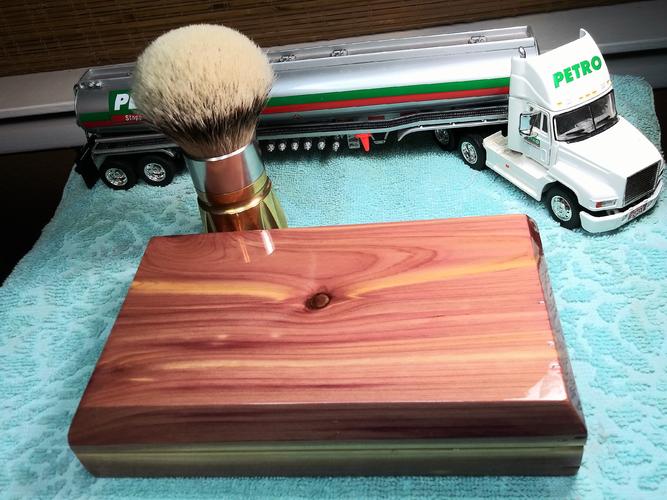

Here is the finished Cedar box. A high gloss coat of poly. I left the inside unsealed so I will get that nice scent when opening it.

Then this morning I made another box of Cedar. This one holds my Tomo too. Not really a Tomo as you can see the color difference, but it's just as hard as the Asagi.

I will go with the magnets again but that's for later.It's just Sharpening, right?

Jerry...

-

06-27-2019, 05:42 PM #16534

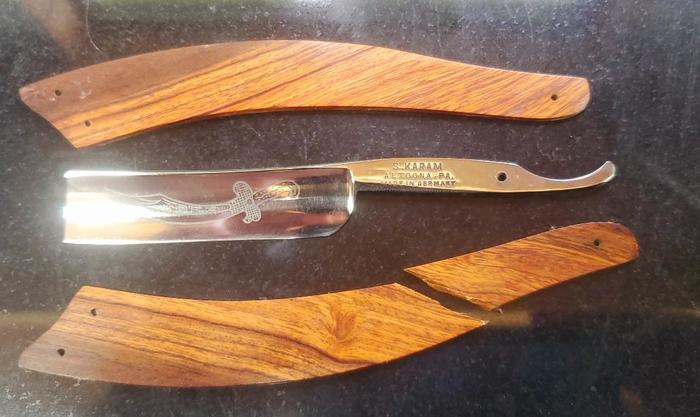

Well, back to the drawing board with some hard lessons learned in the wood department: I snapped the front scale on this desert ironwood set when it was virtually finished. Scale thickness was at about .10." I was sanding out scratches on the inside when this happened. Thing is, I didn't even cuss; I just smiled and shook my head, came in and ordered the same blanks from woodturningz.com. I will make exactly the same design, as I'm trying to complement the "scimitar" motif on the blade face. The 2nd time around, I'll probably back it with G10, so I'll have more structural stability and don't have to sand the flippin' insides!

I'm also working on another TruOil finish on this set in Bastogne Walnut that I'm saving for a gorgeous curvy Wostenholm. Here they are yesterday at 600-grit and the first hand-rubbed coats. I just wet-sanded with TruOil and 1200-grit, trying to fill some of that open grain on this gorgeous quilted piece. (Thinking about getting a can of that Zinsser SealCoat for grain-filling duty).

As for the epoxy-coated red mallee burl, that's kind of in-progress.

Finally, what thickness do you guys usually shoot for with wood? These highly-figured and birds-eyed sets I've been working with lately have been very fragile at around .10". That was the 3rd set I've snapped at close to finished. I may just start backing most of my wood sets with G10; I think it will ultimately be less work if I'm not having to start over on scales!There are many roads to sharp.

-

06-27-2019, 05:43 PM #16535

Beautiful boxes, Jerry!

There are many roads to sharp.

-

06-27-2019, 05:51 PM #16536

[QUOTE=ScoutHikerDad;1877489][SIZE=3]Well, back to the drawing board with some hard lessons learned in the wood department: I snapped the front scale on this desert ironwood set when it was virtually finished. Scale thickness was at about .10." I was sanding out scratches on the inside when this happened. /QUOTE]

Ouch!!! That really stinks! And you don't think you could glue that back together with some good wood glue and clamps? I know sometimes it's unavoidable but that really stinks to throw out beautiful wood like that.Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

06-27-2019, 05:59 PM #16537

I usually go between 1/8" and 3/16" which is a little thick but more round than flat. Also, so far the only wood I've really made scales out of is southern live oak which is so hard a cat can't scratch it and incredibly dense.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

06-27-2019, 06:04 PM #16538

Yeah, in the past I've made thicker wood scales, say between .125" and .140." If they're kind of squared, that ends up looking kinda clunky; they would probably look better more rounded/convex at that thickness. As for hard, dense wood, that desert ironwood is extremely so, but that can also mean brittle!

And with no backing already in place, I don't think I'm going to try to save these, Paul-but thanks for the suggestion.There are many roads to sharp.

-

06-27-2019, 06:15 PM #16539

I haven't done any scales in wood so should probably keep my mouth shut, but I won't. Could the scales be angled to be more with the grain? It looks like the break is exactly in what I would expect is the woods weakest point.

I may not be as old as dirt, but I do remember when the Dead Sea first begin to feel ill!

-

The Following User Says Thank You to Diboll For This Useful Post:

ScoutHikerDad (06-27-2019)

-

06-27-2019, 06:46 PM #16540Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,443

Thanked: 4828

That was also my thought. I don make wood scales either, but Iíve made a thing or two out of wood. In my mind the scale needs to be arranged to the grain runs from pivot to wedge, more or less. At that thickness the cross grain does not really have the strength for produce the needed flex. G-10 is pretty amazing stuff and I love it for liners.

P.S.

The failures or things that did not go well are where we really learn. I appreciate you showing that. We often keep those things to ourselves. I know I most often do. And the trucoil finish is looking great.Last edited by RezDog; 06-27-2019 at 06:48 PM.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

ScoutHikerDad (06-27-2019)

91474Likes

91474Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote