Results 16,541 to 16,550 of 20602

Thread: What are you working on?

-

06-27-2019, 07:07 PM #16541

Could you use a thin backing like a brass sheet? They make them in varying thickness. .01" might be too thin. .032" might be too thick. .020 might be just right. Hey! I'm like Goldilocks!

Seriously though. I just hate to see that beautiful wood go to waste. Of course I'm pathologically cheap.Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

The Following User Says Thank You to PaulFLUS For This Useful Post:

ScoutHikerDad (06-27-2019)

-

06-27-2019, 07:45 PM #16542

Yep, Cutting out scales without the wood grain going close to end to end makes for weak wood. A little angle in the grain is ok, but across like you did... They might have broken just from the flex of the razor. I still shoot for 0.080 with wood. It's doable, you just got to be easy on them you Ham Fisted Brother!

It's just Sharpening, right?

Jerry...

-

The Following User Says Thank You to Gasman For This Useful Post:

ScoutHikerDad (06-27-2019)

-

06-27-2019, 08:14 PM #16543

Thanks for the comments and suggestions, fellas-I did see that the split occurred along a grain line. Those DI blanks from woodturningz.com are 2x6." The angles I cut out were somewhat constrained by the limited maneuvering room in the blank with that unusual scale shape. Patrick at woodturningz got my new blank cut and out the door with tracking almost immediately, and charged me a dollar for the cut; we'll see if I can find a better orientation on the next set, which I will try again AFTER epoxying to .020" G10 liners (which is the perfect thickness, Paul-and I may try some sort of fix yet with that set; what have I got to lose, right?).

Anyway, I concur with Shaun (and say to my students all the time) that we learn more from our mistakes than our successes; maybe sharing mine here in the Workshop contributes to the next guy learning from my errors too and getting it right the 1st time, so it's all good.There are many roads to sharp.

-

06-27-2019, 08:25 PM #16544Senior Member

- Join Date

- Feb 2018

- Location

- Manotick, Ontario, Canada

- Posts

- 2,819

Thanked: 563

We’ve seen Outback accomplish amazing repairs with fibreglass. Would that be a do-able fix with your wood scales?

David

“Shared sorrow is lessened, shared joy is increased”

― Spider Robinson, Callahan's Crosstime Saloon

-

06-27-2019, 10:06 PM #16545

Thanks for the suggestion, David-I just put 'em back together with epoxy over .020" G10 sheets-Paul inspired me to try. Again, I've got nothing to lose, and if it doesn't work, I learned another lesson and have more desert ironwood on the way. I love how this ongoing thread is about people sharing issues and fixes from their workbench; within hours, you've got a bunch of potential fixes-what a great resource for us all!

There are many roads to sharp.

-

06-28-2019, 03:07 AM #16546

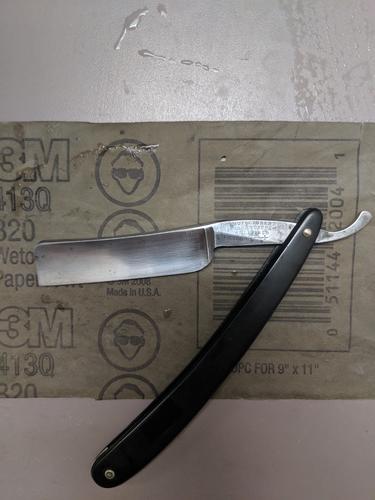

I'm continuing here from the post below.

https://sharprazorpalace.com/razors/...t-project.html

The first round of cleaning. I used 0000 steel wool and bore cleaner (I didn't have any Mother's yet). Then wet sanded with 320 w/d. I didn't de-scale...unscale?... ...

... ... anyway I didn't take the scales off yet. I'll do that next then go through the levels of w/d then the emory wheel, rouge wheel and loose cotton.

... anyway I didn't take the scales off yet. I'll do that next then go through the levels of w/d then the emory wheel, rouge wheel and loose cotton.

P.S. still interested to hear any input or even guesses on production year. Definitely pre-1890s. 1860?... 1870?... Anybody?Last edited by PaulFLUS; 06-28-2019 at 03:13 AM.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

06-28-2019, 03:34 AM #16547Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

The way the makers Mark is done makes me thing it’s a late production model. The makes on older razors are often quite deep. I can’t easily read it but does it say England on it?

It's not what you know, it's who you take fishing!

-

06-28-2019, 03:38 AM #16548Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

At some point you should remove the scales. There is often a lot of ugly hiding under them. Also there is a I bit of a learning curve on the buffer. Go slow and be gentle.

It's not what you know, it's who you take fishing!

-

06-28-2019, 11:06 AM #16549

Last edited by outback; 06-28-2019 at 11:08 AM.

Mike

-

06-28-2019, 12:16 PM #16550

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote