Results 17,031 to 17,040 of 20602

Thread: What are you working on?

-

08-31-2019, 03:02 AM #17031

-

08-31-2019, 03:18 AM #17032

-

08-31-2019, 03:50 AM #17033

It seems the plastic pellets used in the current 3D printers is something with a low melt and not so sturdy.

Something better will come along in that aspect.

The old dies and molds are long-gone, I expect.

The only hope is that these scales will have some survivors to scan as the material gets better..

-

08-31-2019, 12:11 PM #17034

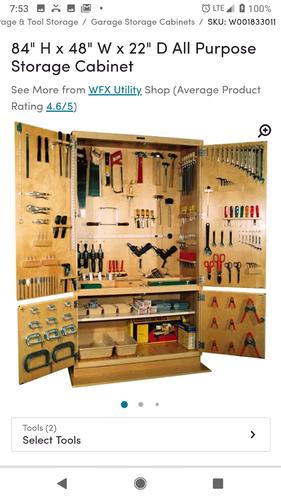

Here's a nice little encased work station for all those projects. The wife sent me this from Wayfarer.com

Edit: when I say "sent me this" I mean sent me the picture.Last edited by PaulFLUS; 08-31-2019 at 12:13 PM.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

The Following User Says Thank You to PaulFLUS For This Useful Post:

Geezer (08-31-2019)

-

08-31-2019, 01:29 PM #17035

-

08-31-2019, 04:34 PM #17036Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,466

- Blog Entries

- 1

Thanked: 4207

Crude resolution and soft plastic, (hot melt glue basically) is why I went the 3d carver route instead of 3d printer when I was building my lil cnc rig couple years back.

Haven’t found the time to start to make hi def scales yet, but I have brushes down pat now on it.

Scales are still in the ‘to learn’ bucket, if I ever slow down at work.

Feel you can, with the right pass rate and bit selection, much more closely replicate the intricate definitions and lines of the old stamped scales on a 3-5 axis engraver than the currently affordable 3d printer rigs.

"Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

08-31-2019, 11:18 PM #17037

Just a reminder, Men! Head on over and vote for the featured Shave of the Month! https://sharprazorpalace.com/shave-d...ave-month.html

-

The Following User Says Thank You to sharptonn For This Useful Post:

RezDog (08-31-2019)

-

09-01-2019, 11:21 AM #17038

Shaun...

I did a couple more scrubbing sessions on the linen and worked the hell out of it on a 3/8 drive 12" long extension a couple times. Than ran the edge of a steel ruler across it for a bit. Its almost softer. Lol. Soon it should be useable without worry. Lot of work just limber that sucker up. Its not feeling exactly like plastic any more.

And yes! Everyone Vote!It's just Sharpening, right?

Jerry...

-

09-01-2019, 02:58 PM #17039Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Jerry, it needs to be soaked, washed and rolled. It can take a week or so of soaking and washing to get years of grit out of the weave and any paste/chalk that was added when new.

You will have to remove the leather handle, and re-sew it back on by hand, not that difficult or take it to a good shoemaker or saddle maker and have them sew it with a machine. A good leather worker can adjust their machine to use the same holes and should not charge too much. Hand sewing is easy and is only the cost of 2 needles and few yards of thread, Tandy leather or on line.

There are several posts on washing strops here is an old one on washing fire hose, (post 52) and demonstrating the hanging roller. Rolling will leave the strop soft and floppy. Rolling also works great with leather, just make sure the leather is well hydrated and oiled, this too can take months, my ¼ inch thick vintage leather strops as a flexible as a wet noodle and work great.

Washing Linen

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Gasman (09-02-2019)

-

09-01-2019, 03:26 PM #17040

Mebbe you can do it like Kanoyama suggests on their newer stuff. Beat it with a mallet!

Seriously, the stuff almost seems like it was compressed/molded.

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote