Results 871 to 880 of 20600

Thread: What are you working on?

-

02-02-2015, 08:24 AM #871

On the other hand I love working with bone.

-

02-02-2015, 01:09 PM #872

-

02-02-2015, 06:53 PM #873

I love working with bone also. It looks like the same bone blanks I buy. It is bleached white bone & comes already contoured for making knife scales or pistol grips but I will split my pieces in two & make one set of scales from one piece.

http://straightrazorpalace.com/razor...ml#post1422154

-

02-02-2015, 07:50 PM #874

Probably using the same blanks Steve. I should soften my statement about "I hate working bone." If I hated it I would not use it. You certainly can not argue that bone is not a great scale material. But the stench of sanding bone makes me nauseous . Sanding horn on the other hand ,does not have the same effect .Maybe I should find a "wet" belt sander.

"It is easier keeping a razor honed than honing a razor."

"It is easier keeping a razor honed than honing a razor."

-

02-02-2015, 07:56 PM #875

Wirm

I love working with horn mostly. The bone does stink more but it comes out nice. I have recently become interested in working on wood & I'm doing some research. I buy my horn & bone scale blanks from a seller known as "standsbyriver" on eBay. I buy rams horn from a different seller.Last edited by engine46; 02-02-2015 at 07:59 PM.

-

02-02-2015, 09:26 PM #876

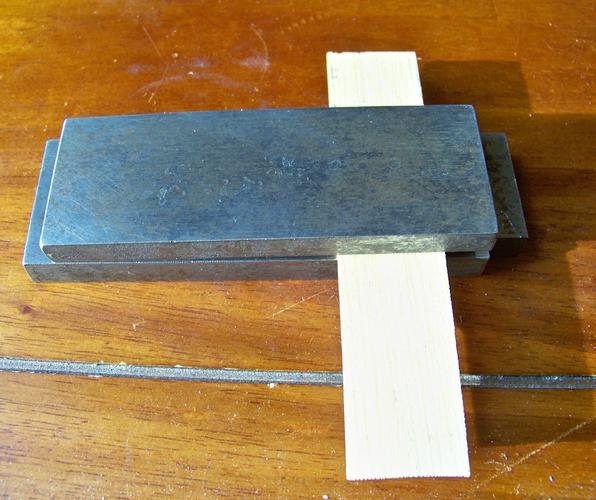

Got my Cerrobend in the mail, but I needed a mold to form a wedge. Was going to go with the mold design mentioned on here, but I was impatient to wait to I got all the stuff needed so I had to improvise. I took two pieces of metal to melt the Cerrobend on and a piece of wood to adjust the thickness of the wedge. Turned out to work pretty well. The wood allowed me to adjust the thickness so I wouldn't have to make a large wedge and cut alot off to where I wanted it. The Cerrobend is alot harder than lead, but still soft enough to be worked easily and I found that it has a more silver color to it rather than the light grey that lead does. Once I formed the wedge I trimmed the excess and filed it to size. The metal I melted it on had a few dings so I had to file some high spots. The razor I made the wedge for sits about 2mm higher than I originally intended, but I like my near wedges to sit alittle higher so I might leave it. With the low melting point of the Cerrobend really made it quite user friendly. It hardens quite fast so I had to work fast. Now to just pin up the razor and its ready for the hones. Don't mind the dust and fingerprints.

-

02-02-2015, 09:46 PM #877

Looking Good! Thanks for the tip!

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

02-02-2015, 10:04 PM #878

[QUOTE=JSmith1983;1455183]Got my Cerrobend in the mail, but I needed a mold to form a wedge. Was going to go with the mold design mentioned on here, but I was impatient to wait to I got all the stuff needed so I had to improvise. I took two pieces of metal to melt the Cerrobend on and a piece of wood to adjust the thickness of the wedge. Turned out to work pretty well. The wood allowed me to adjust the thickness so I wouldn't have to make a large wedge and cut alot off to where I wanted it. The Cerrobend is alot harder than lead, but still soft enough to be worked easily and I found that it has a more silver color to it rather than the light grey that lead does. Once I formed the wedge I trimmed the excess and filed it to size. The metal I melted it on had a few dings so I had to file some high spots. The razor I made the wedge for sits about 2mm higher than I originally intended, but I like my near wedges to sit alittle higher so I might leave it. With the low melting point of the Cerrobend really made it quite user friendly. It hardens quite fast so I had to work fast. Now to just pin up the razor and its ready for the hones. Don't mind the dust and fingerprints.

I have been wanting to do the same thing because I figured the Cerrobend would look better & have more shine & you have now proved my assumption was right. I've been trying to figure a way to make a mold. Richard (geezer) already had a good idea for one. I've been trying to think of something I have here at home since I have so much crap laying around!Last edited by engine46; 02-02-2015 at 11:01 PM.

-

02-02-2015, 10:52 PM #879

The design that I was thinking of using was the one Geezer mentioned, but I needed a few more things to make it work so I just went with what I had since I was impatient. I find myself having to force myself to wait more times than I want because of my impatience.

-

02-02-2015, 11:03 PM #880

I have some aluminum out in the garage I need to find that might work well. If it works, I'll keep ya updated.

91543Likes

91543Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote