Results 4,521 to 4,530 of 20600

Thread: What are you working on?

-

09-01-2016, 03:34 AM #4521Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

Think the final design on that razor stand is pretty sweet.

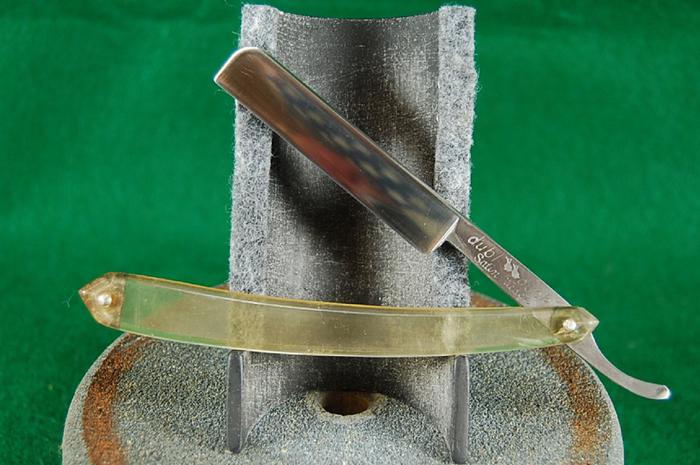

That giant Puma is very nice. it is close to the original look. I like it.

That Valet is an amazing cleanup and as usual very quick.

This is a fast moving thread.It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

outback (09-01-2016)

-

09-01-2016, 03:35 AM #4522Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

Very nice Puma indeed, with the cool box to boot, well done!

-

The Following User Says Thank You to Martin103 For This Useful Post:

MikeB52 (09-01-2016)

-

09-01-2016, 03:38 AM #4523

-

09-01-2016, 06:05 AM #4524

On the hunt for a couple of polish wheels for my bench grinder. Trying for a mirror finish using just elbow grease ain't cutting it.

Last edited by Panama60; 09-01-2016 at 06:16 AM.

-

09-01-2016, 09:56 AM #4525

-

09-01-2016, 02:23 PM #4526Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

@Panama60

The scratches from previous grits are hard to see with my naked eye as I am sanding. I use a 2.5X visor in order to be able to see better. You are correct in that it is not easy and task some practice. I'm not sure wheels for a grinder are going to be a big help. You first need to look at the speed of your grinder. You will also want to extend the wheels away from the machine so you can work with smaller wheels to drop the number of feet per minute down into a cooler speed. All of the power tools have a learning curve, so be careful.

It is tough to restore blade that have been ground so very very thin. It does not take a lot of sanding before they become so thin that they start to flex too much.

It is not a bad start. drop back in to about 1000 grit and see if you can lighten those scratches a little and then work your way back up to 2000 and then steel wool and polish. I find wine corks help my finger be comfortable while providing a nice backer for the sandpaper. Also wet sanding with WD-40 will make the paper less aggressive.It's not what you know, it's who you take fishing!

-

The Following 2 Users Say Thank You to RezDog For This Useful Post:

Panama60 (09-01-2016), ScoutHikerDad (09-01-2016)

-

09-01-2016, 02:54 PM #4527Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

3.50 reading glasses, from the dollar store, work well also.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

Panama60 (09-01-2016)

-

09-01-2016, 03:16 PM #4528

I can barely keep up with this thread! The Puma is so nice, it really came out great and the technical aspect of transferring the inlay was impressive. Lots of good stuff going on here, I'm going to go back through the last few pages when I have more time. Nice work everybody!

-

The Following User Says Thank You to xiaotuzi For This Useful Post:

MikeB52 (09-01-2016)

-

09-01-2016, 05:08 PM #4529

Thanks, RezDog. I appreciate the advice. My 6" bench grinder spins at 3450 rpm and has a 1/2" arbor. I'll clean it up (don't want to contaminate the wheels) and remove the guards (don't tell the Safety Lady, lol). I've found some 6" buffing wheels, but no luck as yet on the polishing wheels. Also found a couple of 4" buffing wheels that I can attach to my variable speed drill. Quality compounds will have to be purchased online. "Welcome to Garfield County, where we don't stock that item, but we can order it for you and charge you another $10 for shipping." I'll keep my eye open for a cork, I'm getting really tired of slicing my fingertip on the edge. I'll probably have to search online for sandpaper as you can only get 1200 grit locally, they give you a funny look when you ask for higher grits, lol.

-

09-01-2016, 05:39 PM #4530Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

I am painfully aware that sometimes you cannot get what you want or need locally. I did buy a bag of corks when in the big city one time, they were with the wine making supplies at a hardware store. I found it odd but fortunate. I do run a 4" buffing wheel in my 1/2" low speed high torque drill, clamped in a bench vise. If you are ordering buffing wheels and grit you should be able to order sandpaper from the same spot. Wet and Dry Sandpaper - Caswell Canada is where I order about once a year. This year I won't have to order as often because I have had little to no time for working on razors and such. It is a good spot and great information about buffing metal on their website.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

Panama60 (09-01-2016)

91543Likes

91543Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote