Results 2,121 to 2,130 of 4688

Thread: The Butchered Blade

-

10-22-2015, 07:04 PM #2121

That does seem a good way to do it. Definitely bookmarked it. I don't think I could trim around this inlay. Too many tiny points and detail. Next one I get which is simpler, I will give it a go. Anyway, I think if this poly goes on well, It will work fine and sort of encapsulate the inlay. It turned up kindof satin, hence the semi-gloss. Still looks pretty good. I will let it dry a day or two and twist, bend, and beat on it. Then, if all seems good, I will invest in a can of the high gloss, I suppose. I have misted clear wheel coating over water based detail on molded celluloid with great success. Perhaps I will try some on top of this poly and see if that makes it pop. Trying to do with things on the shelf instead of spending dough I don't have!

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

10-22-2015, 07:42 PM #2122

[QUOTE=sharptonn;1556832]That does seem a good way to do it. Definitely bookmarked it. I don't think I could trim around this inlay. Too many tiny points and detail. Next one I get which is simpler, I will give it a go. Anyway, I think if this poly goes on well, It will work fine and sort of encapsulate the inlay. It turned up kindof satin, hence the semi-gloss. Still looks pretty good. I will let it dry a day or two and twist, bend, and beat on it. Then, if all seems good, I will invest in a can of the high gloss, I suppose. I have misted clear wheel coating over water based detail on molded celluloid with great success. Perhaps I will try some on top of this poly and see if that makes it pop. Trying to do with things on the shelf instead of spending dough I don't have!

Sounds good Tom. I have faith, you can do it!

-

10-22-2015, 10:46 PM #2123

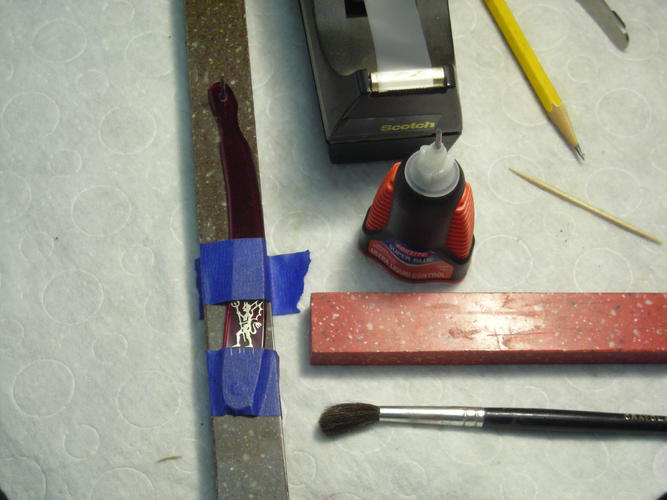

So I have sized my pinholes, located my inlay right where I want it. A piece of tape under it marked where his feet will go.

My plan is now to go with Mike's scotch tape thing. I want something totally flat to set it in CA on. I kindof wonder about wax paper as the wax may come off with the CA? I know CA won't melt Corian, so this piece is the correct width to set my inlay on.

I figure to lay my tape lightly on the inlay where it is on the scale, drop some CA on the corian and spread it around with the brush, Pick up the tape from both ends, set it lightly on the CA, lift, set it on the scales paying particular attention where the feet go. The rest should fall into place. Fastest and best thing I can think of.

Thoughts?

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

10-22-2015, 10:50 PM #2124

I like the concept...not sure I'm steady enough to execute it well.

Just call me Harold

---------------------------

A bad day at the beach is better than a good day at work!

-

10-22-2015, 10:57 PM #2125

Hey guys...

Feelin a bit better this evening, so I polished up the hammer Bill sent me, and some sanding on my Canton, OH. razor.

Well I found something I've never seen on a blade.

I assume probably happened during heat treating, and was never caught, untill now.

Its a stress crack just under the spine

Thought it was a scratch....

But wouldn't sand out.

It runs from just inside the toe, the length of the blade, stopping and starting along the way, going thru the stabilizer and stopping at the letter N.

IT doesn't transfer thru to the other side of the blade thankfully.

Any of you seen this before?

Should i be Leary about it?

Mike

Mike

-

10-22-2015, 11:01 PM #2126

I has seen short ones before but that is a lott longer than any I've seen. Thanks for the photo! Another thing to watch for.

~RichardBe yourself; everyone else is already taken.

- Oscar Wilde

-

The Following User Says Thank You to Geezer For This Useful Post:

outback (10-22-2015)

-

10-22-2015, 11:54 PM #2127

Too bad about that crack, outback!

I am finally done. The tape, loctite CA, and brush went out in a hurry. Spread the CA and stuck it down in it, lifted, and put it on the scale. Did not stick to the scale, but was obvious I got it on the inlay. I suppose it dried before I got there! Managed to save the brush with acetone. Got the end of a toothpick, lightly dipped it in CA and stuck it on the devil's belly.

Then, I used Gorilla gel(which dries slower) and dropped it, spread it with an SE blade, grabbed the devil by his wooden appendage. Down and down. THEN I pressed it all around with my fingers and another toothpick a while. Toothpick and CA on the belly were judiciously cut off with a DE blade. I can see an imprint of it in the dried CA, so I guess I got it all.

Seems quite solid. Enough to polish a bit with a q-tip and be ready to coat the scales.

WHEW!

"Don't be stubborn. You are missing out."

"Don't be stubborn. You are missing out."

I rest my case.

-

-

10-23-2015, 12:02 AM #2128

-

10-23-2015, 12:21 AM #2129

[QUOTE=sharptonn;1556934]Too bad about that crack, outback!

I am finally done. The tape, loctite CA, and brush went out in a hurry. Spread the CA and stuck it down in it, lifted, and put it on the scale. Did not stick to the scale, but was obvious I got it on the inlay. I suppose it dried before I got there! Managed to save the brush with acetone. Got the end of a toothpick, lightly dipped it in CA and stuck it on the devil's belly.

Then, I used Gorilla gel(which dries slower) and dropped it, spread it with an SE blade, grabbed the devil by his wooden appendage. Down and down. THEN I pressed it all around with my fingers and another toothpick a while. Toothpick and CA on the belly were judiciously cut off with a DE blade. I can see an imprint of it in the dried CA, so I guess I got it all.

Seems quite solid. Enough to polish a bit with a q-tip and be ready to coat the scales.

WHEW!

Fantastic work Tom! It couldn't have been done any better & the scary part of what I mentioned was CA on the outer pars but not the middle (belly). I think you made a wise decision & executed the procedure very well. Now I also bookmarked & also sent myself an email of that link for further reference. Awesome work my friend.

Outback, that crack is like wow but since it doesn't go all the way through, you should be ok. Thanks for showing us that.

-

The Following User Says Thank You to engine46 For This Useful Post:

sharptonn (10-23-2015)

-

10-23-2015, 12:31 AM #2130

Yep..

Blew me away...Tom's work that is.

But I found the crack very interesting. I've heard of this happening, from guys that make knives.

They say happens during the tempering process.

Usually when they dip them in whatever solution they use to cool , makes a audible sound like a clickMike

-

13682Likes

13682Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote