Results 2,221 to 2,230 of 4688

Thread: The Butchered Blade

-

10-24-2015, 02:58 AM #2221

-

-

10-24-2015, 03:00 AM #2222

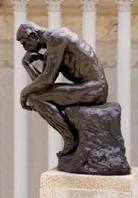

OUTBACK! That looks just like you!

"Don't be stubborn. You are missing out."

I rest my case.

-

The Following User Says Thank You to sharptonn For This Useful Post:

outback (10-24-2015)

-

10-24-2015, 03:02 AM #2223Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

Heating the inlay alone is the way I'll be going, if I do go there. My thinking is they are so thin and would transfer the heat so quickly would be enough. Heating the scale would risk more than it would gain warpage wise and that localized heat, just where it's needed should be enough.

JMO, haven't tried it yet myself either. Like Outback's vinyl tool idea, very neat tool.."Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

-

10-24-2015, 03:13 AM #2224

Why not experiment on an old broken scale if you have a good soldering gun. Clean all the solder off the tip with a file so no old solder sticks to the piece & heat the part up & see if it will met into the scale. I have a soldering gun that gets that hot.

If it works, pick the piece out carefully, smooth the scale down if any melted & squished out. Set the piece back in there to make sure it is flush or close to it. Next do the glue or epoxy job, then clear over it.Last edited by engine46; 10-24-2015 at 04:11 AM.

-

10-24-2015, 03:30 AM #2225

Yep, exactly one good idea to try.

" carefully"

I've also have a iron , that can be switched between 15 or 30 watts.

I've used it on 15 watt setting, for repairing plastic worms for fishin.

Doesnt burn the plastic on that setting, just melts it.

Maybe its a 5-15 watt. Been awhile since used itMike

-

10-24-2015, 03:39 AM #2226

Once again, look at my inlay. I truly don't think you guys know how thin it is.

Heating this would be like wadding it up and tossing it, IMO. I am going for the chemical melt.

Testing....1....2....3"Don't be stubborn. You are missing out."

I rest my case.

-

10-24-2015, 03:45 AM #2227Senior Member

- Join Date

- Dec 2013

- Location

- Virginia

- Posts

- 1,516

Thanked: 237

Also, heating it might cause discoloration. But it's always worth a shot, I'm excited to see these attempts!

-

10-24-2015, 03:49 AM #2228

This is the reason I plan on heating the scale up too.

The scale would not need to be heated to the 120 degrees that is needed to make it pliable. It could go to perhaps 90 degrees... And the inlay would not need to go to the high temp needed to melt room temp celluloid... perhaps just 120 degrees. heating both of the materials up could mean than one or the other doesnt need to reach levels that would destroy it...

Make any sense?

“You must unlearn what you have learned.”

“You must unlearn what you have learned.”

– Yoda

-

The Following User Says Thank You to MikeT For This Useful Post:

sharptonn (10-24-2015)

-

10-24-2015, 03:50 AM #2229Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

Bondic, not laserbond. Thats the stuff at Home depot. As per what I read, it is a liquid plastic 'weld' that won't cure till you hit it with UV light so is repositionable and cleans off easy too.

Might be worth a look Tom. I think, like you that yours is too thin for heat, and flex or slow cure CA or maybe this uv plastic is the way to go. Google Bondic, there's a few commercials on youtube"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

10-24-2015, 03:54 AM #2230

-

The Following User Says Thank You to sharptonn For This Useful Post:

MikeT (10-24-2015)

13682Likes

13682Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote