Results 2,091 to 2,100 of 4688

Thread: The Butchered Blade

-

10-22-2015, 03:24 AM #2091

-

The Following User Says Thank You to sharptonn For This Useful Post:

prodigy (10-22-2015)

-

10-22-2015, 03:30 AM #2092Senior Member

- Join Date

- Dec 2013

- Location

- Virginia

- Posts

- 1,516

Thanked: 237

Definitely NC-17 now for sure!

-

10-22-2015, 03:37 AM #2093

What the hell is that thing?! LOL

-

10-22-2015, 03:44 AM #2094

Just went back and saw. Okay that's a strange pic.

Matheus that is similar to an idea that popped into my mind. I've seen plenty of scales with a different top coat, very thin but it's there, and those are factory.“You must unlearn what you have learned.”

– Yoda

-

10-22-2015, 03:49 AM #2095

A very spiny one, very small too. The thing must be everted from resting position prior to filling (they are kept inverted and deflated inside snake's tail when not in use). Something like a 5mm long inside-out moist sock. Not the smaller I had mounted so far.

A very spiny one, very small too. The thing must be everted from resting position prior to filling (they are kept inverted and deflated inside snake's tail when not in use). Something like a 5mm long inside-out moist sock. Not the smaller I had mounted so far.

Let's enjoy the joke and get back on track, gents. I'll try to make an inlayed disk with something, just to test the idea.

-

10-22-2015, 04:59 AM #2096

I've been gone & just got in, read 3-4 pages of posts. Some thin CA would be good but you would have to be fast or it could get messy. The gel type CA is the one that takes a little longer to setup but it isn't as thin as the other.

I was just wondering if you put the inlay on a piece of scotch tape like B52 said so you can see exactly where you will put it. Turn it over for the glue side & look at it to find some designated areas to dab tiny bits of the thin CA to, using a stick pin, like on the spear, wings, center, tail & each foot. I have a loupe that attaches to my eyeglasses that would help me out.

Flip it over & gently tape it to the scales until the CA has set! I wouldn't press on the inlay either or any CA might seep out so just let 'er sit until dry. I think it would work. It's a tedious job but I think it will work as long as you get just the right amounts of CA on the right applicator.

(after a few minutes)............

I've got it!

Experiment on a broken scale for now. Make something out of wire, anything! Hammer it flat on your anvil if you have to, to simulate the devil. Stick it to some scotch tape, that way you will be able to center it. If a stick pin is still too big, use something smaller like a thin guitar string for an applicator & use it to apply CA to the piece of wire bent whatever shape you made. Flip it over using the tape & lightly put it on the broken scale but don't press on the homemade inlay, let dry. Inspect to see if any seeped out but make sure the wire is on the broken scale. Even if you had a small enough applicator, you could use the gel type CA to keep it from setting up too fast. If all works, then ya know what to do!

Last edited by engine46; 10-22-2015 at 05:27 AM.

-

The Following User Says Thank You to engine46 For This Useful Post:

sharptonn (10-22-2015)

-

10-22-2015, 05:14 AM #2097

Tom, it's too bad you don't have access to the laser cutters anymore or you could use some of that 3M double sticky tape they use for auto & motorcycle emblems. It has a red backing you pull off. That's what I had to use when re-using tank emblems for Harley's & it is what the factory uses also. I had to do it the hard way but they always came & got me to do that. I have some of that tape but if you had access to laser cutters, they could cut a piece of the double sided, thin tape the same shape & that could have been another option. The double sticky carpet tape I use when making scales would work good too & it is thin enough.

-

10-22-2015, 07:00 AM #2098

You HAVE to have a thin coat of CA on the whole thing otherwise it WILL catch an edge when you are wiping the scales down for polishing/cleaning them and you WILL rip the inlay off.

Just my opinion.

Ed

-

The Following User Says Thank You to Chevhead For This Useful Post:

sharptonn (10-22-2015)

-

10-22-2015, 08:15 AM #2099

Yeah Chev, that did cross my mind. After I wrote the previous post I was thinking of a very thin line of the gel type so it wouldn't set up so quickly. You're right about that.

I put a new tank emblem on a Factory Custom Harley (CVO~Screamin' Eagle Model) once & one of the wash guys caught it with a rag & pulled it almost all the way off after I took so long to get it lined up & it had the 3M double sticky tape all on the back side of it! They had to order a new tank emblem again & I had to do it all over when it came in.

-

10-22-2015, 10:13 AM #2100

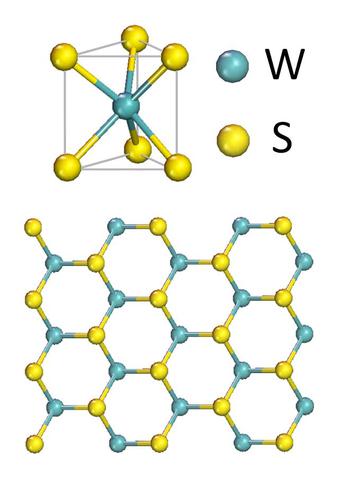

If it were me, I'd contour the inlay for the new scales, and photo them with a monolayer exitonic laser. I would then place the photo (1:1) on the scale, and use a depth setter for the thickness of the transfer. From there I would pull out a spintronic fun size plasmonic repro stick. After that lads, it's straight on 'til morning.

Here is what it will look like graphically with W being the scale and S being the inlay.

"Call me Ishmael"

"Call me Ishmael"

CUTS LANE WOOL HAIR LIKE A Saus-AGE!

13682Likes

13682Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote