Results 21 to 30 of 66

Thread: W&B 8/8 FBU shorty project

-

09-27-2019, 09:35 PM #21

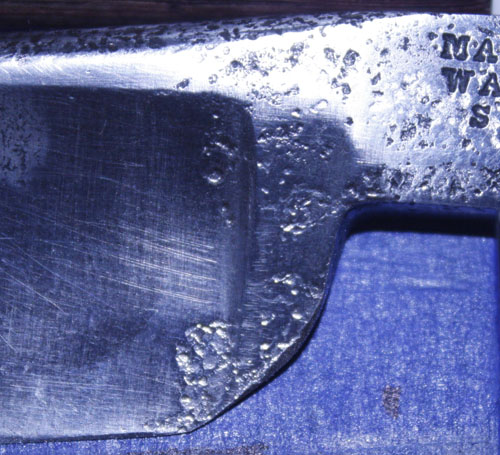

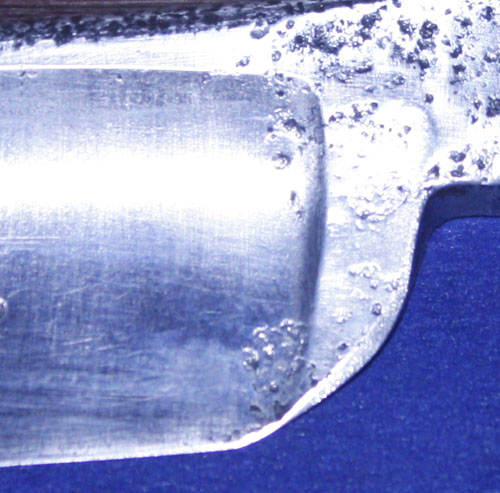

Did some extra filing on the heel. Better?

O'Toole's commentary on Murphy's Law: Murphy was an optimist.

O'Toole's commentary on Murphy's Law: Murphy was an optimist.

-

09-27-2019, 09:48 PM #22Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

It’s better. You need to consider how much the edge will be raised once you finish honing. The edge should be slightly forward of the stabilizer and the heel should be a little higher than the edge. I hope that makes sense. Both Oz and Marty have done some tutorials on it but I can’t find them from this device.

It's not what you know, it's who you take fishing!

-

09-27-2019, 10:30 PM #23

I set a rough bevel before I began, so the edge shouldn't raise much when I finish honing. Yes, your description makes sense. I've only done this a couple of times, so I appreciate having some more experienced eyes look at it. I watched one of the videos a while back and it was quite helpful.

O'Toole's commentary on Murphy's Law: Murphy was an optimist.

-

09-28-2019, 02:40 AM #24Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Yea, I would move the end of the edge, so it is about a ¼ inch in front of the stabilizer. I would move the corner past the pitted steel, a bit more than ¼ inch.

When you set the bevel, you will remove close to a 1/16 inch of width which will move the end closer to the stabilizer. Especially for a razor with issues and/ or has been buffed, (edge removed) you have both, so it may take you a bit of work (steel removal) to get to a good edge.

If you ride on the stabilizer it will keep the heel half of the edge off the stone. It is easy to round the heel more, (steel is thin) if needed. But it will make honing easier, if you don’t have to worry about hitting the stabilizer.

CA & horn dust makes a good match, build up patches in layers. Tape one side fill with a bit of dust and add CA. If you use a kicker, you can fill a lot quickly. Sands and polishes well.

I don’t think you want pristine scales anyway, if you do make new one from horn. Horn is inexpensive and works easily, buffs very well.

Here is an old post, (How to correct/re-profile a heel)

-

The Following User Says Thank You to Euclid440 For This Useful Post:

JellyJar (09-28-2019)

-

09-28-2019, 09:59 AM #25

With that pitting i think your going to loose more of that ende at the heal before its clean steel. As Marty and shaun said, push that edge forward past the pitting. Then hone her. I bet you will find the edge result being the edge closer to the stabilizer but still below it if you do. Marty uses circles. Use a bigger circle than what you got now. But you are close.

It's just Sharpening, right?

Jerry...

-

09-28-2019, 07:28 PM #26

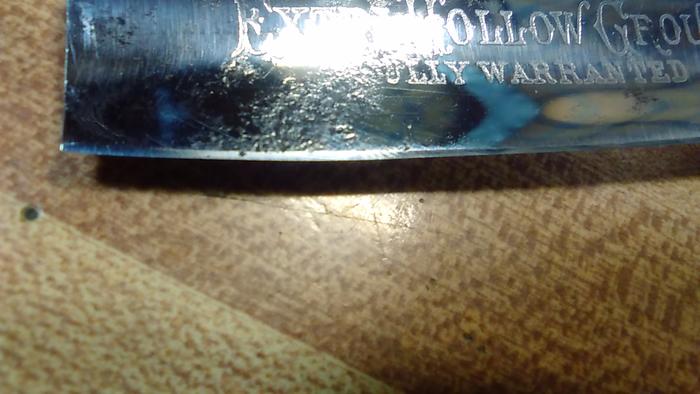

I get what you're saying, but I feel like I'm walking a bit of a tight rope with this one. There's multiple pits near the edge on the back side. I feel like if I take it much further I'll just chase pits until the blade is dead. It's really close now, but has clean steel at the edge. I did a little more and set a bevel at 600-800?K. I'll still need to finish the bevel 1K and up. I'm not sure I want to go much further.

The back side edge (heel on the left)

O'Toole's commentary on Murphy's Law: Murphy was an optimist.

O'Toole's commentary on Murphy's Law: Murphy was an optimist.

-

09-28-2019, 07:38 PM #27Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

The poor steel often extends around and down from the pits so you may never find solid steel, but you may so you need to go looking for it. Sometimes it looks good at 1K but won’t hold up past 8K

It's not what you know, it's who you take fishing!

-

09-28-2019, 11:04 PM #28

Ah, good to know. I'll cross my fingers and hope it doesn't fall off at 8K. I knew this was a long shot when I started, hopefully it will be functional.

O'Toole's commentary on Murphy's Law: Murphy was an optimist.

-

09-28-2019, 11:32 PM #29

Got faith for ya, JJ. I think it'll make it. I've got one with pits in the bevel but not the edge. Its held up for over two years.

Mike

Mike

-

09-28-2019, 11:43 PM #30

You have worked it back enough to give it a go. Good luck on finding solid steel. Ive got a few razors that i have gotten luckg with and a few that just wouldnt come around. If nothing else you now have a good idea on working the heal.

It's just Sharpening, right?

Jerry...

143Likes

143Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote