Results 71 to 80 of 155

Thread: Is this microchipping...

-

01-08-2016, 11:52 AM #71

-

01-08-2016, 12:17 PM #72

Thanks! Sounds like the question is whether to try to step back a little and see if I need to step back more, or go back to 1K and try to come back up. Will think about this a bit to see what makes sense for me. Most of the blade looks pretty good.

Do you think I need to be lighter handed, as I get to 8-12K, and not worry so much about pressure on the toe/heel?

My overall goal is to learn how to maintain all my razors, so I'm willing to treat them all as "honing exercises". I don't have any expensive blades, so I won't be heartbroken, if there are problems honing. That is mostly why I picked up the JA Henckels - it was $20 and in bad shape - I'm enjoying learning to hone on that razor just recently, even with the problems.

This Spike that I'm honing now, I bought through the classifieds, and was reasonably inexpensive. So again, no tears if things don't work out. However, It is my favorite razor so far w.r.t. shave feel, so I'm trying to take more care (less risk?) in the honing process. But you're right, I know this has some issues with spine wear, and the problems honing the heel and toe. I'm hoping it will be recoverable and will hone up OK, as I really like the feel of this blade.Regards,

PCM

-

01-08-2016, 01:06 PM #73

@Euclid440 Regarding cell rot, I don't know. Is that from decay of the scales or some such (I vaguely recall something about gases from the scales eating at the metal)? These look like the original scales, old, and have the Spike name on them.

Regards,

PCM

-

01-08-2016, 02:01 PM #74

Last edited by JOB15; 01-08-2016 at 02:03 PM.

-

The Following User Says Thank You to JOB15 For This Useful Post:

pcm (01-08-2016)

-

01-08-2016, 04:38 PM #75Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

It’s a bad steel issue, Spikes came in a variety of scales, the translucent and some white/ivory are cell rot candidates and the grinds are very thin, which is why they are great shavers. And any rust, no matter the cause will do the most damage at the thinnest part, the edge.

The chipping to that edge is shallow, it looks deeper under magnification. Jointing on the 8k and resetting is very possible and will remove the least amount of steel and quickly reset.

So, yea you can always breadknife or reset on a 1k and work up the progression, but if you want to learn, remove the least amount of steel, you can always drop down if you need to.

Yes, you can use too much pressure, but with the 12k SS it will not chip the edge like you are experiencing, that is bad steel. We don’t know what is underneath, and removing just a bit may be enough.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

pcm (01-08-2016)

-

01-08-2016, 08:01 PM #76

-

01-09-2016, 02:04 AM #77

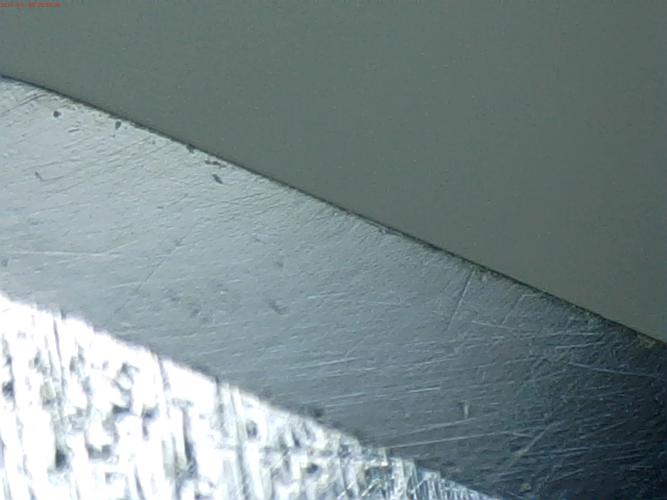

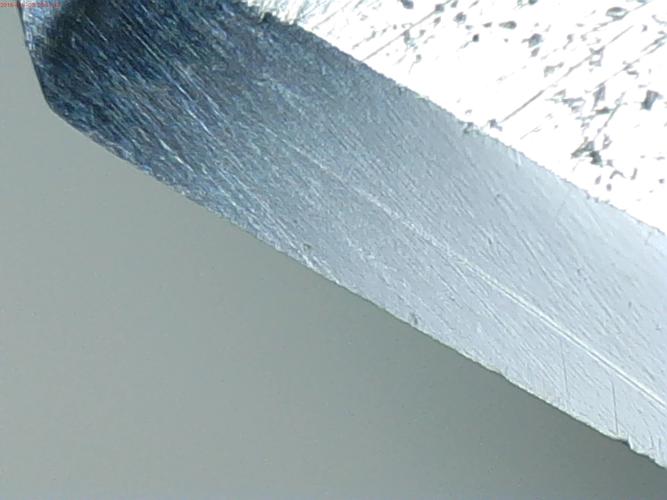

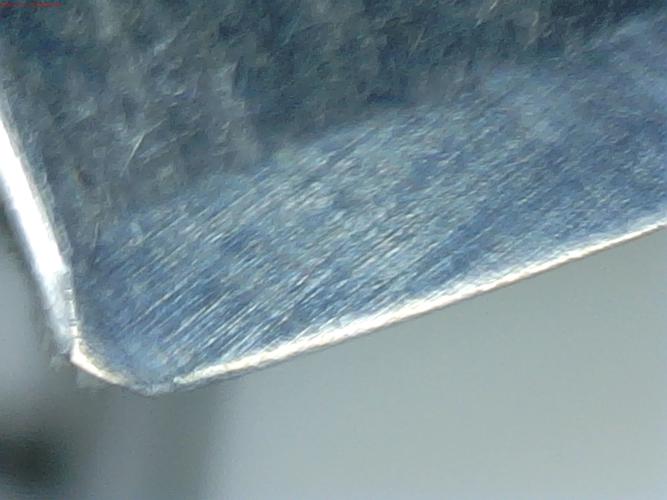

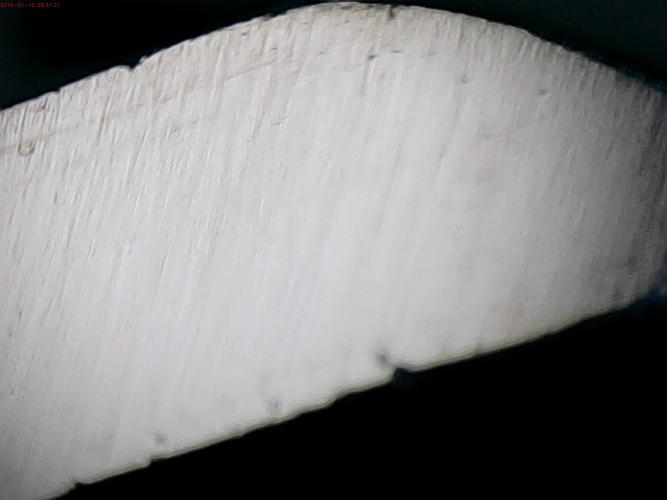

I ran the edge on the corner of the 8k stone, and then put on one layer of tap and did rolling X strokes, with light pressure. Here are shots near the toe, on both sides, where the worst of the chipping was. This is with max resolution:

To give an idea of scale, the one shot has the 1mm ruler. I'm not sure if I'm maybe getting hung up on "pixel peeping".

Thoughts on how to proceed on this?Regards,

PCM

-

01-09-2016, 05:02 AM #78Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Looks better, but stay on the 8k and see if it will hold an edge, it should come together rather quickly, don’t be afraid to joint and reset the edge.

By repeated jointing and re-setting you are removing just a small amount of the edge and a little more at honing. You are trying to sneak up on good steel between the pits. Jointing allows you to start with a straight edge, then hone a bevel to an already straight edge, as opposed to hone a bevel, to a straight edge, that may or may not reveal a pit.

Or you can just hone on the 8k and see if the edge will hold and stop chipping. Get the edge straight first and get the bevels to meet then, go to the 12k and polish.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

pcm (01-09-2016)

-

01-12-2016, 02:50 PM #79

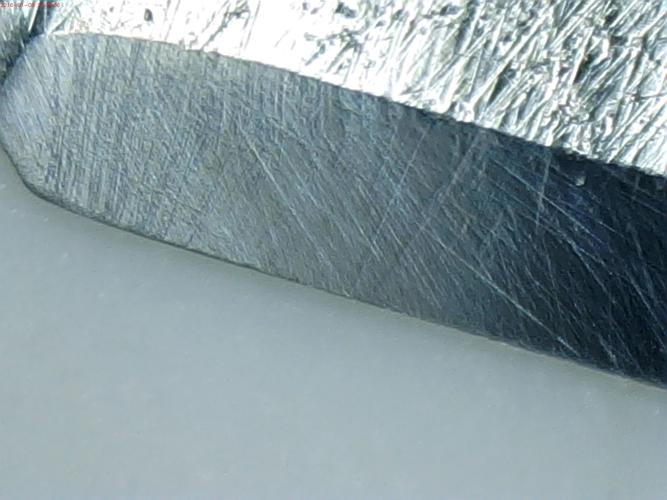

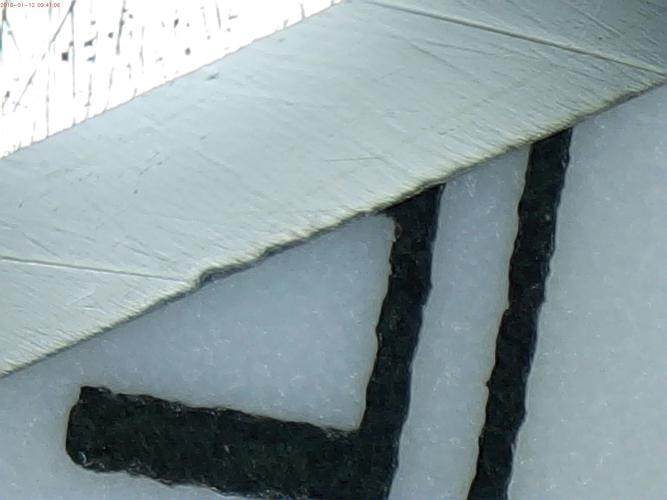

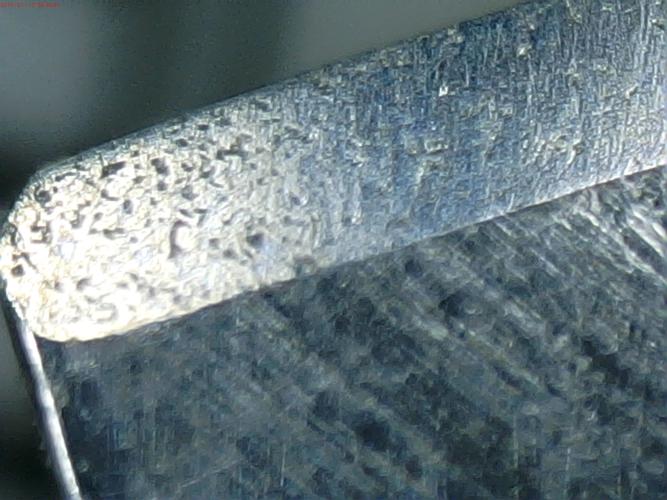

Hmm. Did a bunch (120+) rolling X strokes, and jointed the edge in the corner of the stone twice. There are some flat spots, and under high magnification, there is chipping in numerous places and the toe doesn't look good at all (pitting):

Am I using too much pressure or too many passes on the jointing (I thought I was doing it very lightly, 2-3 times) causing larger flat spots?

Should I drop down to 4K (or 2K or 1K) to try to take metal off faster? Seems like I have not hit good metal.

Any other suggestions?

Seems like I took a step backwards...Regards,

PCM

-

01-12-2016, 03:01 PM #80illegitimum non carborundum

- Join Date

- Jan 2008

- Location

- Rochester, MN

- Posts

- 11,552

- Blog Entries

- 1

Thanked: 3795

Drop down to 4k as you thought, clean up the edge there and then progress back up. This time don't bother trashing (jointing) the edge along the way. It might be your honing pressure and it might be your steel. Either way you are honing and looking, so you are learning--even if it doesn't seem like it right now.

-

The Following User Says Thank You to Utopian For This Useful Post:

pcm (01-12-2016)

47Likes

47Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote