Results 10,671 to 10,680 of 20574

Thread: What are you working on?

-

09-11-2017, 11:02 AM #10671

Lookin good, Jerry.!!

Gotta keep the TDB full enough to carry through the winter..!Mike

-

09-11-2017, 12:10 PM #10672

Not really easier to restore a wedge, they do have a slight hollow to them, there is more metal to play with as you said. Starting with the least invasive method is always best until you get the hang of what you need to do.

Finding a razor with little rust and putting is a good start often 0000 steel wool and wd40 will clean them and then metal polish. Stay away from power tools, power tools can wreck a blade and or hurt you. In the beginning hand work is best. Sand paper wet dry variety around 600 to 2000 grit and mothers mag and aluminum polish or Maas, flitz are all good polishes.

Now honing is a whole different rabbit hole and usually best if you do your restore and send it to a reputable honer to get that part taken care of. Keep asking questions and reading up. Take care.Nothing is fool proof, to a sufficiently talented fool...

-

The Following User Says Thank You to ejmolitor37 For This Useful Post:

engine46 (09-11-2017)

-

09-11-2017, 12:31 PM #10673Member

- Join Date

- Sep 2017

- Location

- Sundsvall, Sweden

- Posts

- 93

Thanked: 8

Thanks. Wont be honing yet. That might happen in the future, but have a few nice guys I can send them to. Steel wool and wd40 i have. Also sand paper up to 2000grit. Will buy some pins and washer and a drillbit to try remove scales and refresh them to.

Have a battery powered "dremle" thats real low speed that i have used with great care to polish sometimes, might try that to.

Skickat från min ONEPLUS A3003 via Tapatalk

-

09-11-2017, 12:45 PM #10674

Be careful drilling out pins. Its easy to slip the bit off and into the scale. Be sure to center punch them but even then...

I started with a buffer and compounds and now find that doing by hand is a lot safer and you dont end up with a blade that is a mirror finish as must didn't come that way. Its more work sanding by hand and takes longer but I think the outcome is more correct and enjoyable.

Start with something that dont need a lot of work and no script on the blade face as you will sand it away if your not careful. And as Cudarunner (Roy) said, A few battle scars, black spots, pitting left on the blade shows its age. I like a clean piece of steal as much as the next guy but you need to learn the weigh the difference. Spend hours and hours sanding and take a chance of damaging a razor by putting too much work in one area or live with a little color and pitting.

Good luck and enjoy. I'm honing now days with Synthetic stones, and manage to do a decent job but now I'm working on learning the Naturals stones (Coti and Thuri) and that is another animal. Not getting anywhere with them yet but I aint giving up. If it can be done, I'll figure it out!It's just Sharpening, right?

Jerry...

-

09-11-2017, 01:54 PM #10675Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,454

Thanked: 4830

When selecting your drill bit, a split point bit will be a better choice than a regular bit. Also if you get a pin vice with a split point bit you can start holes or do delicate jobs carefully by hand.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

Geezer (09-11-2017)

-

09-11-2017, 02:01 PM #10676

-

The Following User Says Thank You to ejmolitor37 For This Useful Post:

Geezer (09-11-2017)

-

09-11-2017, 07:20 PM #10677

Or a flat cutting side cutter.

-

09-11-2017, 08:47 PM #10678

Yep,

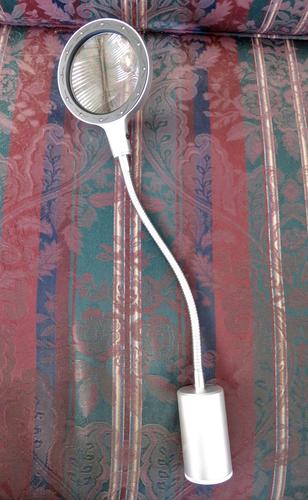

I have the flush cutters like Tim said but when I have some collars I want to save, then I carefully drill them out. I actually do that with the small drill press I got plus I just got an awesome flexible light with a magnetic base that works great on it. It uses 3 AAA batteries & has 12 LED's.

I also agree with ejmolitor37. Use your hands & don't attempt to use any power tools, especially a Dremel to polish a blade until you know you are well experienced with it. All it takes is a slip or to try to polish a blade with the tool spinning the wrong direction & you can trash a blade in a nano second. Use progressions of wet or dry sandpaper like he also said. I have 230 grit up to 3k grit & polish like he said with Maas, Flitz plus I also have some Mothers.

Jerry is also right about being careful when drilling out pins. A drill bit will walk on you especially if it isn't center punched very good & you can trash some good scales.

Some nice razors there Jerry. I was actually looking at a Shapleigh Snap 35 I have, this morning.

-

The Following User Says Thank You to engine46 For This Useful Post:

Svisson (09-12-2017)

-

09-12-2017, 12:15 AM #10679

Did some research this morning and found the name "Shapleigh" for the Snap. I couldn't read what was printed on the back of the tang so had to go looking for it. Thanks.

I just posted on the Hone of the day thread that I got 5 razors honed today. The four I posted here and one that was just not right. I find I'm really hating near wedge razors. They are harder to hone and I'm not really happy with the shave ether. Now the one I have that are early 1800's are not going anywhere but will probably part the the others some day as I'm running out of room in my displays.It's just Sharpening, right?

Jerry...

-

09-12-2017, 12:22 AM #10680Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,454

Thanked: 4830

It is really hard to take an old near wedge, beat yo and then worked on and then set the bevel. I have founds that getting the entire bevel to be true all at once takes either one long swing or several swings. Sometimes a lot of material needs to be removed due to the width of the bevel. If you look at the volume of metal removed to form a bevel from scratch on a big fat old wedge and then compare it to a full hollow or extra hollow razor they are simply night and day. That's why it takes so much effort to build that very first bevel. To get a big wedge to shave the way it should can sometimes be a dedicated task requiring more than one visit to the hones. I do not try to do them in one sitting anymore. After about thirty minutes my honing gets sloppy and I am counter productive. Time to clean it, put it away and work on another blade.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

outback (09-12-2017)

91475Likes

91475Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote