Results 1,071 to 1,080 of 20600

Thread: What are you working on?

-

05-29-2015, 04:32 AM #1071

-

05-31-2015, 12:35 AM #1072

I'm working on a mold I can make some wedges from using Cerrobend. I'll show it when it's done.

-

05-31-2015, 01:12 AM #1073Senior Member

- Join Date

- Jan 2011

- Location

- Roseville,Kali

- Posts

- 10,432

Thanked: 2027

-

05-31-2015, 01:25 AM #1074

-

05-31-2015, 04:25 AM #1075

I've been making alot of wedges from cerrobend since I got it. I don't have a mold. I just press it between two steel plates that are spread apart at one end when its melted and cut and file to shape. I like the fact that it can be melted and formed really easy. Looking forward to seeing the mold.

-

05-31-2015, 05:13 AM #1076

That sounds a good idea!

So far, I cut two pieces of 1/8" thick aluminum & about 4.75" long. I took them & made them flat on a DMT 600 honing plate. I'm going to figure out the size of "V" I need for my wedges which will be like a universal wedge. I have some 0-80 screws that I use for mocking up a straight razor. I have a drill & tap coming which I'll use to drill, tap & mount two 1/8" thick aluminum square pieces on the ends of the longer pieces once I figure out my"V". The square ends will hold the mold up. It might be crude but I'm going to try it.

I just did some thinking. I can make some more square pieces so that I can take it apart & make different thicknesses.Last edited by engine46; 05-31-2015 at 05:33 AM.

-

05-31-2015, 05:51 AM #1077

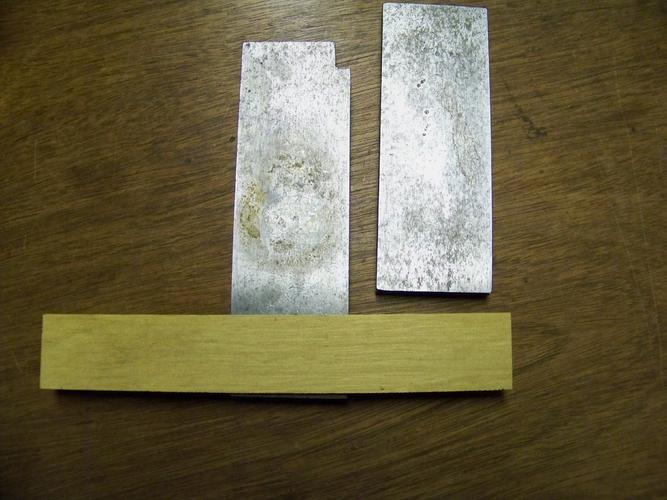

This is what I use to make the wedges till I can decide on if I want to make a mold. I was thinking of milling a block of wood to form a general pattern, but this stuff seems to cool really fast. I have to heat up the steel plates before hand otherwise it will cool down the cerrobend before I can squeeze it. I might just keep doing it this way since it works. I was also thinking of putting a hinge on two pieces of metal to make it easier to squeeze to shape. Two steel plates and a piece of wood about 2.5mm thick. The closer the cerrobend is to the wood the wider the wedge is. I just cut excess off and file to shape. Cerrobend shines up brighter than lead I think. Quite user friendly.

Last edited by JSmith1983; 05-31-2015 at 05:56 AM.

-

05-31-2015, 05:59 AM #1078

[QUOTE=JSmith1983;1502273]This is what I use to make the wedges till I can decide on if I want to make a mold. I was thinking of milling a block of wood to form a general pattern, but this stuff seems to cool really fast. I have to heat up the steel plates before hand otherwise it will cool down the cerrobend before I can squeeze it. I might just keep doing it this way since it works. I was also thinking of putting a hinge on two pieces of metal to make it easier to squeeze to shape. Two steel plates and a piece of wood about 2.5mm thick. The closer the cerrobend is to the wood the wider the wedge is. I just cut excess off and file to shape. Cerrobend shines up brighter than lead I think. Quite user friendly.

That's a great idea. The cerrobend shining up better than lead is my reason to make a mold for it. A hinge is a great idea!

-

06-03-2015, 07:29 PM #1079

Finished a pairing knife and kitchen knife that I have been working on. I unfortunately messed up a slipjoint that I have been working on twice, so nothing to show there.

-

06-03-2015, 09:02 PM #1080

[QUOTE=williamc;1503767]Finished a pairing knife and kitchen knife that I have been working on. I unfortunately messed up a slipjoint that I have been working on twice, so nothing to show there.

Looks good to me! Congrats on the fine work.

91534Likes

91534Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote