Results 13,611 to 13,620 of 20602

Thread: What are you working on?

-

07-21-2018, 11:17 PM #13611

Drill Doctor!!! Forget the little ones...but they can be sharpened using a graver guide and a 3 power loupe.

A few of many...

graver-sharpener

~Richard

PS Harbor Freight has one also in the honing and jewelers' stuff. Cant remember what they call it.Be yourself; everyone else is already taken.

- Oscar Wilde

-

07-21-2018, 11:37 PM #13612

I've sharpened 1/8th " and larger, on a bench grinder, the small ones with pocket hones. Split point... buy new ones

Mike

-

-

07-22-2018, 06:00 PM #13613

When I was sharpening machine shop tools, we sharpened anything from small drill bits to large twist drill bits & also spade drill bits. I have sharpened some twist drill bits 2"-3" in diameter & spade drill bits over 6" in diameter. We sharpened high speed steel, cobalt & carbide. I would like to get myself a small bit sharpener. I also have some left handed bits that need sharpening but I don't think the Drill Doctor does that but I could always get them to my friend where I used to work. When buying drill bits, spend the extra money & they will work for you. Iv'e seen people buy the cheapest bits they could find & they wouldn't drill through wood!!! It always pays to spend a few more bucks & have it work rather than to be disappointed with something that wouldn't even cut.................like using razors & knives from Pakistan.

Had to use diamond wheels on carbide. I remember going home everyday with grinding dust all over me & couldn't wait to get into the shower. I knew never to rub my eyes or anything like that until I showered.Last edited by engine46; 07-22-2018 at 06:04 PM.

-

07-22-2018, 07:54 PM #13614

Ive tried to sharpen bit in the past. I gave that up for just replacing them. The time and effort and bad grinding made it worth buying new. But that was just me in my longhaired, dope smoking days. No wonder i couldnt sharpen them.

It's just Sharpening, right?

Jerry...

-

07-23-2018, 12:02 AM #13615Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,465

- Blog Entries

- 1

Thanked: 4207

Made a few more pens.

Maple burl, fossils and bits, faux abalone, and alligator jaw with red alumilite, left to right

And turned a little gift for my nephew. A kaleidoscope in babinga.

Sort of a cross between a lava lamp and a kaleidoscope really, but he should enjoy it..hold it with the plastic tube vertical and look through the eye piece at the end of the turned wood. Voila, psychedelic blobs and such as the stuff in the tube settles from one end to the other. Just what a 4 year old needs..

"Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

-

07-24-2018, 02:29 AM #13616Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,465

- Blog Entries

- 1

Thanked: 4207

Tonight I was really curious what these would look like turned. So made one after dinner.

Actual computer circuit boards encapsulated in acrylic, then turned to shape.

Perfect for IT guys..

My goal is to try to turn a bit of everything to decide what I like the most. Plus build up some inventory as my daughter and wife are both keen on peddling some of this stuff to friends..

Cheers gents.

I have an idea on using some of the brass rounds to make fusion style razor and stand combos as well, maybe brushes..

Cheers."Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

The Following User Says Thank You to MikeB52 For This Useful Post:

outback (07-25-2018)

-

07-25-2018, 02:49 AM #13617

Yep, I've done the same Mike, by hand. It's really not that hard, just have to put enough clearance behind the cutting edge & make it even.

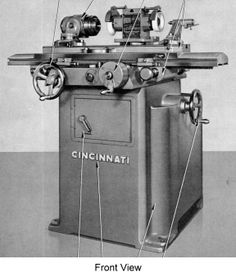

When I was sharpening the machine shop tools, i would sharpen endmill's also on a special fixture that when I would chuck an endmill in it, it had compressed air going to it so that I could rotate it & move it in & out because the compressed air was inside a "chamber" with the part that rotated & moved in or out which is how I would move the fixture on a table which was on a Cinncinati grinding machine. They had 5 of these machines setup for different things. I loved it, it was fun. These are the machines which I mentioned one came off a battleship & another came from the Springfield Armory. I found a couple pics on the internet. They are big & require a forklift to move them around.

They had a huge dust collecting machine in there to pull a lot of that dust out of there plus we had to constantly brush dust off them.Last edited by engine46; 07-25-2018 at 03:26 AM.

-

07-25-2018, 04:11 AM #13618

Okay, I have been searching for this old post & I finally found it. Some of you remember when I used the "compass" thing (I know they aren't called that) to make a smile on a Wosty I have?

Look here:

https://straightrazorpalace.com/work...ml#post1779960

Then here:

https://straightrazorpalace.com/work...ml#post1786425

The scales on that Wosty were all warped so bad, I had to manipulate the blade back in to close it. I was trying to clean up in my garage the other day since I have been felling a little better except for the migraine's I wake up with but anyway I found this old iron that may have been my moms.

Since it was rusty & dirty I cleaned it up because I thought to myself, "hey, I wonder if this will fix warped scales"? I used the back side of a DMT to have a flat surface & the iron surface is pretty flat so I tried it. Low & behold, it works better than any other way of fixing warped scales I have known, at least for horn. I imagine it might work for the bakelite on a lower temp which this iron has. I straightened the scales on the Wosty & I have a James Barlow that had scales about the same & I got them straight.

Wosty before:

Wosty after:

I forgot to take before pics of the Barlow:

Each time when the scales were straight & the blade would be to more one side, I flipped one of the scales over & set the iron on it. It fixed 'em. Now they center up nicely. I just need to pin 'em back together.Last edited by engine46; 07-25-2018 at 04:21 AM.

-

-

07-25-2018, 05:04 AM #13619

Nice work on those warped horn scales. Evidently old irons aren't just good for waxing snow skis. Nice repurposing!

-

The Following User Says Thank You to Speedster For This Useful Post:

engine46 (07-25-2018)

-

07-25-2018, 07:32 PM #13620

Nice job and a cool looking iron too. I think grandma had one like that. Nice job cleaning it up.

It's just Sharpening, right?

Jerry...

-

The Following User Says Thank You to Gasman For This Useful Post:

engine46 (07-25-2018)

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote