Results 18,101 to 18,110 of 20573

Thread: What are you working on?

-

03-12-2020, 02:29 AM #18101

-

03-12-2020, 02:59 AM #18102

O'Toole's commentary on Murphy's Law: Murphy was an optimist.

O'Toole's commentary on Murphy's Law: Murphy was an optimist.

-

The Following User Says Thank You to JellyJar For This Useful Post:

Montgomery (03-12-2020)

-

03-14-2020, 03:06 AM #18103

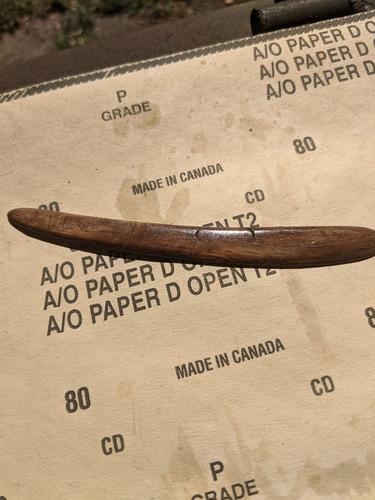

Done shaping the scales for the Christiensen. Probably done sanding too. This is quick sanded to 2k and rubbed with cotton to remove dust. No stain, no finish just sanded wood.

Caliper measured them to 1/8" which is roughly .0078" more than the originals.Last edited by PaulFLUS; 03-14-2020 at 03:09 AM.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

03-14-2020, 03:49 AM #18104

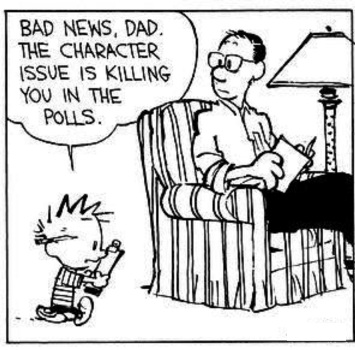

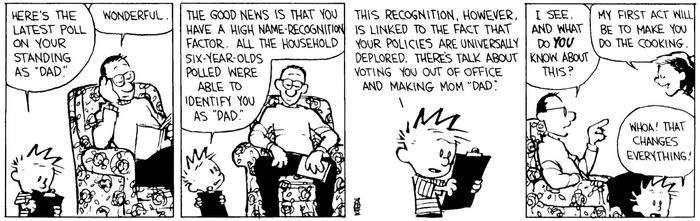

I'm not quite sure it your conversations at times were like mine but I've always liked these examples of how kids 'CAN' think of us dads--

Attachment 317366

I hope all the Dads out there enjoyed--Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

03-14-2020, 04:05 AM #18105

-

03-14-2020, 04:27 PM #18106

Flexible enough. That's 1/8" at the thickest part. This stuff isn't that flexible if you get it paper thin. Applied Tru oil and it wouldn't penetrate the wood at all. It all dried streaky and grainy.

I went over with 000 steel wool like it says in the directions( actually it says use 00) and it took it all off. It didn't really add to the look either which surprised me. I guess because it didn't penetrate. I'll probably go back to the gunstock wax. Even with that I had to apply then leave it in the sun for it to soak in before and it didn't soak up much even then.Last edited by PaulFLUS; 03-14-2020 at 04:29 PM.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

03-14-2020, 10:24 PM #18107

Bee's wax and orange oil, works pretty good on black n white ebony. Its dense, like what your talking about.

Mike

Mike

-

03-14-2020, 11:04 PM #18108

Those look really nice Mike. This stuff reminds me of ironwood it's so dense. I started listening to my own words and said wait a minute. If it's already dense and not that flexible even at paper thin then I should probably go even thinner so I took it down about another .0025. I've been a little concerned that as I thin it down those cracks through it might become a problem not so much with strength but with it catching on things so I made another scale for that side. It's a lot easier to make them both at the same time than make another one after the fact but they look more uniform now. Beeswax and orange oil sounds interesting. I've never used that before but it sounds like an interesting combination. I've had pretty good luck with that gun stock wax so I already started slathering that on. It will actually soak some of that up given time and sunlight. I might give the beeswax and orange oil a go at some point.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

03-15-2020, 12:16 AM #18109

Beautiful, Paul-I too would be concerned about that crack or void in the one scale snapping under the bow if there's too much angle on your wedge. I had to learn the hard way to back structurally questionable (but still beautiful) wood with G10 liners-still looks good and much stronger. In fact, I just finished up one in birdseye black cherry burl with liners for that very reason. I may post a pic later.

As for the finish adhesion, have you tried removing the surface oils with acetone or denatured alcohol? Also, if you could sand in a 1st sanding wash thinned about 50/50 mineral spirits with 600 grit paper, and just sand rigorously with your TO mixture until it starts to get tacky, then gently wipe to even and fill the grain some. I bet that would adhere. If so, then you can sand in thin coats all the way up to 2-3k. But Mike is the TO guru here.

edit: On looking at the shiny, fine 2k polish in your pics again, I can see why it won't take up the TO-no pores to let it in. Again, sand down to 600, thin it, and sand in a wash coat. I was re-coating the front end on one in Walnut I just finished up-I love that stuff!Last edited by ScoutHikerDad; 03-15-2020 at 01:38 AM.

There are many roads to sharp.

-

03-15-2020, 01:26 AM #18110

It was this Joseph Allen NonIXL in stabilized book-matched black cherry burl given to me by knife maker friend. I didn't trust all those eyes not to snap, so epoxied my thinned scales to the G10 liners.

I made the wedge from another scrap piece of rosewood, though in retrospect I wish I had just thinned it some more and let it be more wedge-like. In any event, it is incredibly strong, and certainly could flex safely. Oh, and it took a smokin' edge without really even trying-I love when that happens!

I learned a hard lesson last summer on this one in desert ironwood that I snapped trying to polish it up (which DI takes the most beautiful natural polish of any wood IMO-definitely going to build more with that stuff!). As a desperation move that I just knew wouldn't work, I managed to push the two epoxied ends together while also setting them on the G10 liner as a hail Mary move trying to save those beautiful scales.

Somehow the gods smiled and it worked. You can see the break along the grain line. Lesson learned, but I learned a lot saving those scales!Last edited by ScoutHikerDad; 03-15-2020 at 12:42 PM.

There are many roads to sharp.

91473Likes

91473Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote