Results 18,321 to 18,330 of 20574

Thread: What are you working on?

-

04-10-2020, 11:31 PM #18321

My 1st ever attempt switching scales. I have limited resources living in a small-ish apartment in the city (no shop ). So I read up a bunch, watched some vids and ultimately, my best resources were on this forum. That was a huge factor in my decision to pursue membership.

). So I read up a bunch, watched some vids and ultimately, my best resources were on this forum. That was a huge factor in my decision to pursue membership.

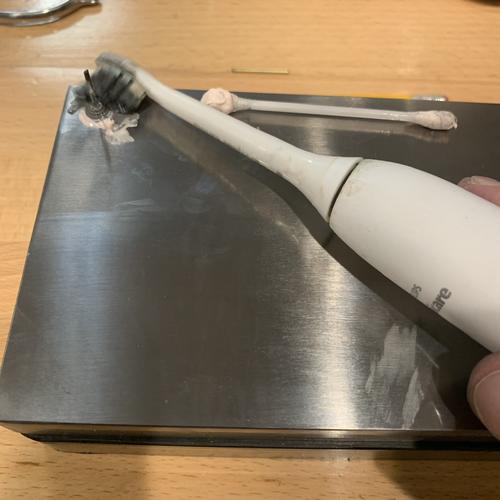

I picked up a few missing pieces and unfortunately had to order some scales off everyone’s favorite auction site. The products I received were “iffy,” but usable. The hardware was in various conditions of corrosion so I employed on old gunsmithing trick. A little Simichrome on an old, trimmed brush for my fancy electric toothbrush made quick work of the tarnish problems.

“iffy,” but usable. The hardware was in various conditions of corrosion so I employed on old gunsmithing trick. A little Simichrome on an old, trimmed brush for my fancy electric toothbrush made quick work of the tarnish problems.

Here’s the finished product, pictured with the tools (sans sandpaper) I used. I learned several critical lessons on this job. Overall there were no critical failures and the work stands functional, so I’m calling it an overall success.

I put considerable effort into shaping up the camel bone scales. Sanding progression from 320-400-600-800-1500-3k left an outstanding finish. The blade is too small for this size scales and my drilling decisions are questionable. Also, the wedge is quite poorly finished. I received a micarta piece in the kit that I had to shape by hand with sandpaper. Pretty rough work but functionally sound nonetheless. Let’s just call it a “rustic” installation (lol).

I’ll end up switching these scales for something more appropriate and use these for another project I’m already looking forward to finishing.

-

04-10-2020, 11:47 PM #18322

We learn by doing. Looks okay in the pictures

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

04-10-2020, 11:57 PM #18323

You might consider Brad and Cassie's website for scales/materials.

https://www.maggardrazors.com/produc...tion-supplies/

You can actually make scales with just a coping saw, some sand paper and a lot of patience in a small apartment.

Have fun, stay safe and stay healthy-----Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following User Says Thank You to cudarunner For This Useful Post:

SilverSwarfer (04-11-2020)

-

04-11-2020, 12:24 AM #18324Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,455

Thanked: 4830

Making scales is not a snap, it’s not rocket science either. My first couple sets we less than perfect. If you got a functional set of scales on your first attempt, your starting ahead of me. Bone is also an excellent product. I love working with it and horn.

It's not what you know, it's who you take fishing!

-

04-11-2020, 12:31 AM #18325

Regarding horn- I enjoy the material very much. I have seen multiple warnings that it tends to warp and/or split. This has raised considerable doubt in purchasing from the auction site I unfortunately turn to often. Hence the bone decision.

While I really really like the feel of bone, I’d also like to work with some horn. Are there any further or specific opinions about it being particularly difficult to work with? Or if particular sources or configurations may be “safer?”

-

04-11-2020, 12:43 AM #18326Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,455

Thanked: 4830

Given your shop situation, I would suggest a jewelry saw over a coping saw. It’s a little slower, but much safer in terms of tearing the layers. I tend to rough shape the outline with the coping saw, file to refine the outline, scraper to shape, then wet sand. Horn works very fast with this process, and with all the power tools at my disposal, I work horn by hand it that fast. There are a lot of places to get scalpers, and you can make them from broke large bandsaw blades, but I order regularly from Lee Valley, so it just makes sense for me. You likely have many options. Any wood working ship with a half decent selection of hand tools will have cabinets capers.

It's not what you know, it's who you take fishing!

-

The Following 2 Users Say Thank You to RezDog For This Useful Post:

Geezer (04-11-2020), SilverSwarfer (04-11-2020)

-

04-11-2020, 03:29 AM #18327Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

Horn is definitely the way to go, easy to work, comes in a variety of colors, easily finished with a minimum of hand tools, drilled with just a hand drill, and is cheap.

It will not crack or bend if an oiled occasionally with a bit of Neetsfoot oil.

Here is a great tutorial on how to make a pair of horn scales with hand tools. (Making Horn Scales)Last edited by Euclid440; 04-11-2020 at 04:30 AM.

-

The Following 2 Users Say Thank You to Euclid440 For This Useful Post:

randydance062449 (04-11-2020), SilverSwarfer (04-11-2020)

-

04-11-2020, 04:43 AM #18328

Rezdog is overly modest. He does some pretty amazing work with bone. I admire his modesty but don't be deceived. He does fine work with this medium.

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

04-11-2020, 05:03 AM #18329Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,455

Thanked: 4830

That’s a great link Marty.

Paul, I’ve made some cool scales for certain, but that’s not how I started. I’ve fumbled a few, we all improve over time.It's not what you know, it's who you take fishing!

-

04-11-2020, 09:53 AM #18330

Good links for scales making. It takes making a few before you will get all the kinks worked out. Possision of the pins and the best shape for the wedge for the blade. Then how thin to make the scales. It can all be found on thd web or our site. Just go slow. Ask questions if you cant find the answer. He will be happy to help.

It's just Sharpening, right?

Jerry...

91475Likes

91475Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote