Results 2,111 to 2,120 of 20602

Thread: What are you working on?

-

02-25-2016, 05:34 AM #2111

The bits are kinda nasty but worth it for the results. I like to do restorations with the scales on and the fiberglass pen is great for getting the pivot area. It's also a great tool for removing rust without removing patina.

B.J.

-

02-25-2016, 05:51 AM #2112

This is a boat I cut the rotten wood out of, then ground the fiberglass back down to the hull and transom. Then glassed new wood back in.

So you think about how bad I itched, compared to a pencil or insulation. Those two are like a mosquito bite, in comparison [emoji4]Mike

-

-

02-25-2016, 06:49 AM #2113

Fantastic work machine gun Mike! I once had to do some motor work on a cigar boat. It had two high performance 502 ci big block Chevy motors in it. Each one ran opposite rotation from the other & the props were also reversed from each other. Also had to do a little transom work where it had rotted out a little just above the outdrives. Me & my buddy took it out for a test run on the lake & couldn't even open it full throttle or the lake patrol would have been on our @sses like ticks on hound dogs! Whewww...........what a wild ride it was anyway!

-

02-26-2016, 04:02 AM #2114

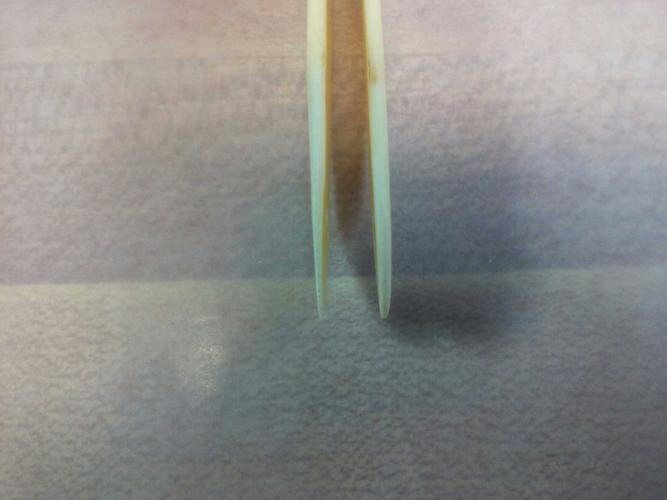

A bit of bone scale repair, with CA and soda.

Bleached these out for four days using 3% hydrogen peroxide, wich worked pretty good for the condition they were in.

After allowing to dry for a couple days, their ready for repairs needed.

#1. Left scale is slightly deteriorated and has become thin, and a crack on the wedgde end, that will need filled and built back up

#2. Right scale has a area that has been erroded by the rust that was on them originally, and will be filled as well.

Before peroxide:

After peroxide:

The areas in need of repair:

This will be done using thin, slow cure CA, baking soda, and CA accelerator .

Mike

Mike

-

The Following User Says Thank You to outback For This Useful Post:

Geezer (02-26-2016)

-

02-26-2016, 04:08 AM #2115

-

The Following User Says Thank You to outback For This Useful Post:

sharptonn (02-27-2016)

-

02-26-2016, 09:02 AM #2116

I finished the box and completed the razor.

-

-

02-26-2016, 09:28 AM #2117

Fantastic job Gipson! Looks really good.................

-

The Following User Says Thank You to engine46 For This Useful Post:

Gipson (02-26-2016)

-

02-26-2016, 03:20 PM #2118

Excellent work gentlemen!!!

-

-

02-26-2016, 06:37 PM #2119

Great work Outback & Gipson.

Tony

-

-

02-26-2016, 08:50 PM #2120

Tonight I am having a go at making a strop. It's out of English bridle leather that came pretty dry and rigid. I have been conditioning it with pure neatsfoot oil off and on then hand rubbing. Now Onto the handle.

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote