Results 3,111 to 3,120 of 20602

Thread: What are you working on?

-

04-23-2016, 12:45 AM #3111I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

Doing a quick cleanup on this Clauss Barbers Special I found a while back in the wild. Probably save this one to hone at Maggards meet coming up.

Burls, Girls, and all things that Swirl....

Burls, Girls, and all things that Swirl....

-

The Following User Says Thank You to HARRYWALLY For This Useful Post:

ultrasoundguy2003 (04-23-2016)

-

04-23-2016, 01:24 AM #3112

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

The white gleam of swords, not the black ink of books, clears doubts and uncertainties and bleak outlooks.

-

04-23-2016, 02:19 AM #3113

-

04-23-2016, 02:25 AM #3114

What make is it.. I might have one

Mike

-

04-23-2016, 02:28 AM #3115

-

04-23-2016, 03:05 AM #3116

..............................................HAR! ...............................

Looking at it now and seeing the hollow there, I expect it might be missing a ball bearing or two? A shaft? Got the windchimes done!

Got the windchimes done!

The music the thing makes is awesome! You can gather all the blades in your fist and just let go fast. A different song each time!Last edited by sharptonn; 04-23-2016 at 04:52 AM.

"Don't be stubborn. You are missing out."

I rest my case.

-

04-23-2016, 12:12 PM #3117

Nope.. No cap for that!!

Mike

-

The Following User Says Thank You to outback For This Useful Post:

sharptonn (04-23-2016)

-

04-23-2016, 12:35 PM #3118I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

Just a cool pic of some blades I need to work on.

Burls, Girls, and all things that Swirl....

Burls, Girls, and all things that Swirl....

-

04-23-2016, 07:39 PM #3119

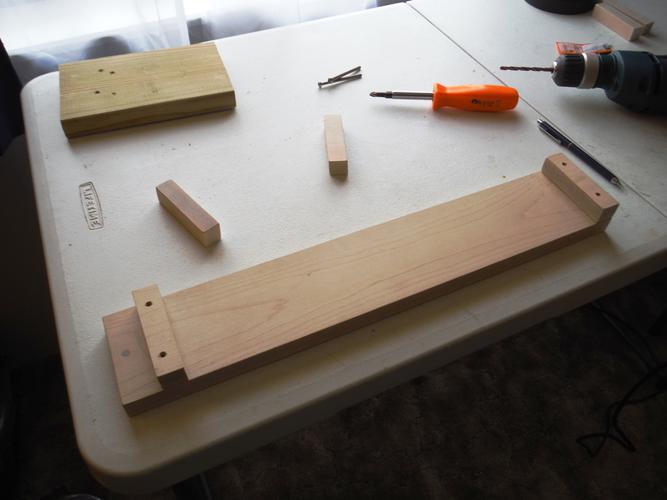

Today, as part of a continued effort to get that buttery edge, i took some tutelage from a one Mr. Sharptonn, and built some balsa paddle strops.

Tom i varied slightly from your instructions based on what i could find. Thanks again for the help.

Quick run down..

Cut 20" long pieces of 3.5" x .75" walnut board, and 8 small blocks from the same. The balsa is 3/16 thick and 18" x 3".

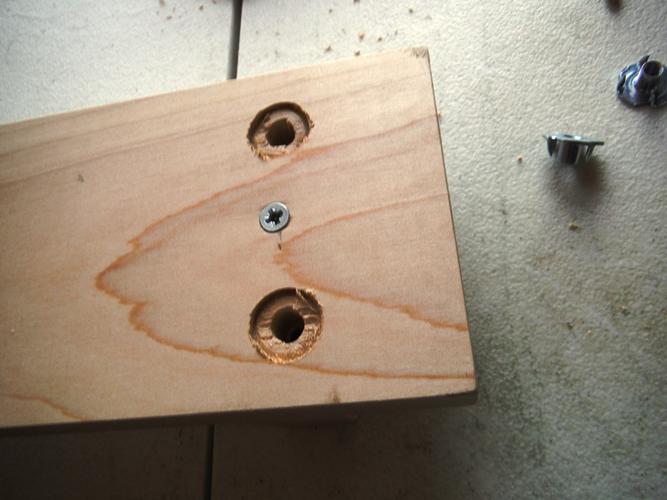

Pre drilling mock up.

I countersunk holes and used t-pins on the bottom. I glued the bottom blocks on then used one wood screw to hold them in place.

T-pins. I used a peening hammer to adjust the angle so the bolts went in straight from the other side.

Top view.

#10 machine screws. Today on the way back to Home Depot i learned there is a difference between and #10-24 and a #10-32 bolt.

Heres both of them all done. I hit the walnut with some Howards Feed & Wax and Minwax. I couldn't help myself.

Now i just have to wait for the fancy honing powders i ordered to arrive from across the seas. Delivery estimate was May 5th.. ugh.

Time for a shave, then a beer.

Thanks for looking guys.Last edited by MW76; 04-23-2016 at 07:42 PM.

-

-

04-23-2016, 08:51 PM #3120

-

The Following User Says Thank You to jmercer For This Useful Post:

sharptonn (04-27-2016)

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote