Results 4,611 to 4,620 of 20602

Thread: What are you working on?

-

09-05-2016, 02:38 PM #4611Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

Panama,

I don't see where the nose on that blade is broken. Unless of course you are talking about the crooked grind at the nose in of the spine. I have no idea why, but it is not uncommon for those to be crooked. I just leave them crooked, clean but crooked.

:-)It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

Panama60 (09-05-2016)

-

09-05-2016, 02:39 PM #4612

@ RezDog - anxiously watching the stain job, nice work.

Still sanding on my Dubl Duck, there are a few scratches that might be too deep, will take it to a mirror finish and think about it.

While taking a break, I've been thinking about my John Pitt's Celebrated Razor (with nice bone scales) and what to do about it's

broken nose. Grind or no grind? I would really appreciate some opinions on this one.

-

09-05-2016, 02:42 PM #4613

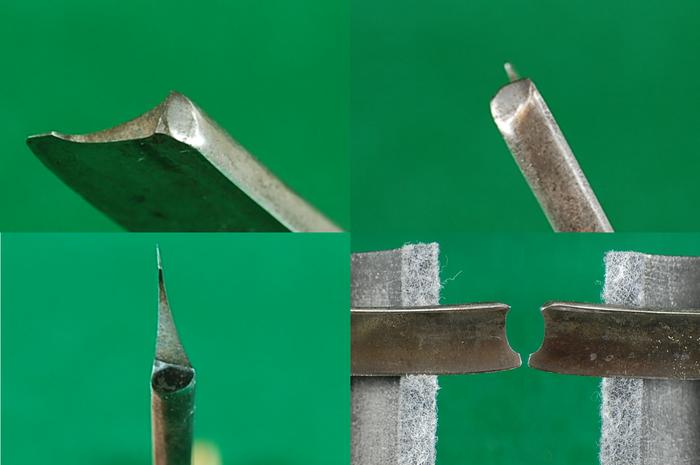

It's broken. It's hard to see, but there is a flat spot above the break that is stress flattened, like it was hammered.

-

09-05-2016, 02:57 PM #4614Historically Inquisitive

- Join Date

- Aug 2011

- Location

- Upstate New York

- Posts

- 5,782

- Blog Entries

- 1

Thanked: 4249

The nose looks fine to me, but looks like there might be some grinding required at the stabilizer to get it to hone correctly.

-

The Following User Says Thank You to Martin103 For This Useful Post:

Panama60 (09-05-2016)

-

09-05-2016, 03:06 PM #4615

I believe you guys are right. Looking at the nose thru a 16x loupe, I see striations, not crystals, so not broken, uneven grind.

There is uneven wear along the spine. Will set this one aside and label for my first pro hone.

-

09-05-2016, 03:12 PM #4616

No problem Freddie.

Once you get those fully polished they will really POP! That particular pattern is called Molten Metal and it's what walleyeyman used to make my brush out of.

For those that may be wondering the product came from Woodturningz. For a small fee they will cut the Acrylic spindles into 1/8" blanks (Sorry but they won't do the wood blanks to due warping concerns). They have a Huge Band Saw and the blades cut a really nice even piece. I ask for a small clean up cut and on average I get 7 blanks.

If you want to have a block cut, contact them and talk to Fritz as he's the Sales Manager.

Here's a link to the website:

WoodTurningz

Here's the link to the Large Inlace Acylester Spindles:

Inlace Acrylester Spindles - Woodturningz

No all I've got to do is make some scales, but it's so nice out and I hear the bike calling Our house is as Neil left it- an Aladdins cave of 'stuff'.

Our house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

The Following 3 Users Say Thank You to cudarunner For This Useful Post:

dinnermint (09-06-2016), Geezer (09-05-2016), Martin103 (09-05-2016)

-

09-05-2016, 05:06 PM #4617

The washer was broken on the front of the pivot pin, so I decided to remove the pin, thinking I would

The washer was broken on the front of the pivot pin, so I decided to remove the pin, thinking I would

protect the scales, filed the mushroomed head off and....oops! Oh well, not the original scales anyway...saving

the bits, don't know if I can patch bone this thin.

-

09-05-2016, 05:29 PM #4618

Time to go to the stickies here and read-up on unpinning scales, Panama.

Pins are often swollen by peening and are 'seized' to the scales, particularly bone and ivory.

They must be properly and carefully drilled-out.

No worries. We all learn by busting things.

-

-

09-05-2016, 05:30 PM #4619Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,457

Thanked: 4830

That is a tough part to repair because of the stress it takes. You can save those by lining them with very thin G-10. It comes at 1/32" thick and will bolster those up. Combine them with some of the Babar collars that Tom uses on delicate scales and they will be just fine.

It's not what you know, it's who you take fishing!

-

The Following User Says Thank You to RezDog For This Useful Post:

Panama60 (09-05-2016)

-

09-05-2016, 06:05 PM #4620

Yep. I usually preach "small steps allow small mistakes, big steps allow big mistakes". I just HAD to take that big step, lol.

Found some nice black G-10 liner at .03" (1/32") thickness, should look nice against the bone.

Pardon my "newbness", but what is a Barbar collar, please?

I can feel my Random Acquisition Disorder kicking in.....Last edited by Panama60; 09-05-2016 at 06:22 PM.

91550Likes

91550Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote