Results 9,611 to 9,620 of 20573

Thread: What are you working on?

-

05-26-2017, 03:42 PM #9611

-

05-28-2017, 03:44 AM #9612

Well, that took some doing! And it also took turning more steel than I expected into dust... but I managed to get a decent edge on that Henry Sears and got a good shave from it this morning.

Around halfway between the heel and toe, there was a lot of pitting, right down to the edge. This blade is now a 13/16", but what I like about wedges is there is so much metal to work with, so despite all the pits I was finally able to get a completely clean bevel.

Also! The spine is 5.50 mm at the heel and 4.52 mm at the toe. If you're going to have a spine that varies in width, wouldn't you think you'd put the widest part of the spine where the blade is widest? So you could keep the same bevel width, for example? Nope! This guy's backwards. So I did three layers of tape at the toe, two in the middle, and one at the heel. And a lot of differential pressure while honing.

What a pain! But it was a sweet shaver -- I'm still feeling pretty smooth 14 hours later, which is pretty unusual for me.

-

The Following User Says Thank You to jmabuse For This Useful Post:

sharptonn (05-28-2017)

-

05-28-2017, 03:46 AM #9613

Cool! The strop will make it better and better! Great work!

I always say it ain't a razor until it shaves!

-

05-28-2017, 04:04 AM #9614Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,463

- Blog Entries

- 1

Thanked: 4207

Nice bevel set gymnastics.

Will be experiencing similar pain soon enough as I'm working on an old wedge as well.

Sounds like your efforts paid off.

"Depression is just anger,, without the enthusiasm."

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

05-28-2017, 04:35 AM #9615

-

05-28-2017, 04:40 AM #9616Senior Member

- Join Date

- Feb 2013

- Location

- Haida Gwaii, British Columbia, Canada

- Posts

- 14,454

Thanked: 4830

The heel on that old girl looks like there is a lot of bevel there. It must have been quite the chore. Glad you made it through.

It's not what you know, it's who you take fishing!

-

05-28-2017, 08:55 PM #9617

a spiny problem

a spiny problem

I was looking at a razor I've had in the cabinet for a few months. Looks pretty much unused. But I was going to take it upstairs, clean it, and hone it when I noticed... it felt a little loose in the pivot. So I thought I'd peen it a little more. But when I tightened it up, it wasn't centered. So I tried a few tricks I learned by reading some of the collected works of Professor Sharptonn. They usually work... but I just couldn't get it far enough. And then I thought, "Hmm, actually these scales are a little warped. I'll unpin it and give them the heat treatment."

And the scales are in fact warped... but it was also starting to look to me like the spine was warped.

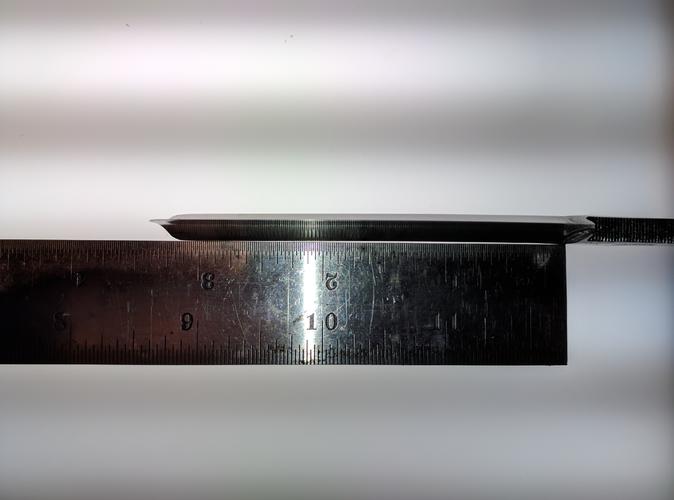

So I took a closer look and -- well here, let me show you.

By the way, that dirty scratched up straightedge is an old Brown and Sharpe. It's straight.

So... how likely is a razor to crack or shatter if I hit the spine with a deadblow hammer? It's bowed up about 1/64", more or less in the center. The bowing continues in the tang -- actually maybe a little more there.

I know you can't predict what'll happen if I hammer it -- I'm not asking you to be responsible and tell me it depends on the razor and the tempering and the steel and the hammer and the vise -- I'm just asking you if you ever said, "What the hell, I'll give it a bang with a deadblow," and had that work out for you. Or did it always end with a busted razor?Last edited by jmabuse; 05-28-2017 at 09:46 PM.

-

05-28-2017, 08:59 PM #9618Senior Member

- Join Date

- Jul 2016

- Location

- Addison Michigan

- Posts

- 627

Thanked: 115

Bad Idea!!Ty

-

The Following User Says Thank You to Addison For This Useful Post:

jmabuse (05-28-2017)

-

05-28-2017, 09:00 PM #9619

Lessee it from the end. Browne and Sharpe is likely a microtome.....

-

05-28-2017, 09:27 PM #9620Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

No, that will not straighten it, break itů possibly.

Nothing good will come from hitting itů

But why hit it?

That amount of warp is not unusual. Slid the heel over a half inch. So it is hanging off the surface and the rest of it will be flat on the hone. A rolling x on the other side will hone it just fine.

You roll the concave side down, the convex side up, by the amount of light visable, just a pressure shift and allowing the heel to fall off the stone.

Not a big deal at all.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

jmabuse (05-28-2017)

91473Likes

91473Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote