Results 1,471 to 1,480 of 4688

Thread: The Butchered Blade

-

10-05-2015, 11:34 AM #1471

"Call me Ishmael"

"Call me Ishmael"

CUTS LANE WOOL HAIR LIKE A Saus-AGE!

-

10-05-2015, 12:36 PM #1472Senior Member

- Join Date

- Dec 2013

- Location

- Virginia

- Posts

- 1,516

Thanked: 237

-

10-05-2015, 12:51 PM #1473Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

G'day I leave 1/32-1/16" between the toe of the blade tip to the top of the wedge inside corner as measured when closing. Using the microfastener nut and bolt combo to mock everything tight first.

Any more and it seems to look to far away when fully closed.

It's all measured in the arc when closing, and having a good pivot pin. If you have a lot of slop at the pivot, you will need more wedge clearance to ensure no impact in the future.

YMMV.

Happy Monday lads!"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

The Following User Says Thank You to MikeB52 For This Useful Post:

WW243 (10-05-2015)

-

10-05-2015, 12:57 PM #1474Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

I'd possibly increase the taper on the wedge to increase the outward bow, but it looks like your better working the pivot end. Try using a washer on the one side, inside between the scale and blade. Try one side or the other and see what the blade does, how it reacts. Will tell you if you need to sand the inside, or possibly move your pivot pin some.

I hate when it doesn't just fall into place.

Good luck and try lots of washer scenarios before committing to drill or sandpaper.

Cheers"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

10-05-2015, 04:12 PM #1475

-

10-05-2015, 04:19 PM #1476

Alllright. Going back to post 1277 here, the razor I completed there has responded wonderfully to another regimen on CroOx, pile of leather. This morning's shave was quite a treat! Purposefully grabbed AQV after to check for 'burn'.

T'was none!

Last edited by sharptonn; 10-05-2015 at 05:08 PM.

"Don't be stubborn. You are missing out."

I rest my case.

-

The Following User Says Thank You to sharptonn For This Useful Post:

cheetahmeatpheonix (10-15-2015)

-

10-05-2015, 04:27 PM #1477Senior Member

- Join Date

- Dec 2013

- Location

- Virginia

- Posts

- 1,516

Thanked: 237

i remember trying to use that sanding of the pivot end method, and i could never figure it out. ill look up that thread again and see if i understand it better. i dont think the washer idea mentioned is going to be enough to correct the issue, and i dont like the idea of having a bunch of washers. the razor has some pitting here and there, but it has the factory mirror finish and zero hone wear.

-

10-05-2015, 05:43 PM #1478

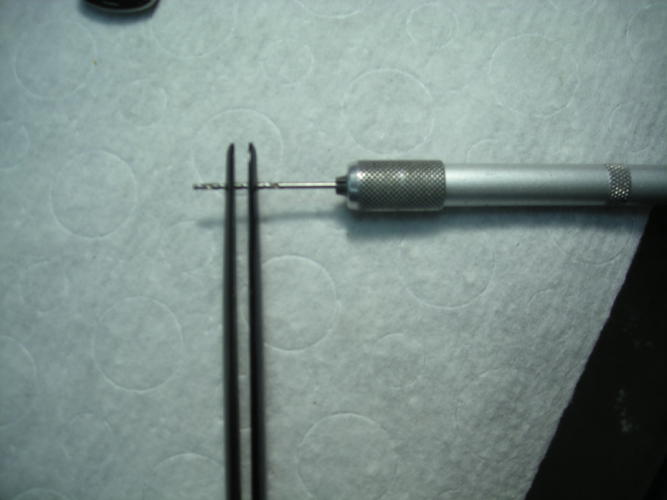

First things first, unbolt the top and see if the pin-holes are even.

If not, saw back and forth with the bit, putting a bind in the right direction. Make certain a bit of leaning is possible the direction you want to go.

You can also pin it up with the blade in a bind to push the pins over.

A tiny bit at the pivot means a lot at the end!

Before you do anything, look at where the tang goes into the scales. If the tang is hitting one side and pushing the blade over, sanding on the inside of the offending scale may be in order."Don't be stubborn. You are missing out."

I rest my case.

-

The Following 6 Users Say Thank You to sharptonn For This Useful Post:

Geezer (10-06-2015), Hirlau (10-07-2015), JoelLewicki (07-05-2016), Leatherstockiings (10-05-2015), MikeB52 (10-05-2015), MikeT (10-06-2015)

-

10-05-2015, 05:56 PM #1479Senior Member

- Join Date

- Dec 2013

- Location

- Virginia

- Posts

- 1,516

Thanked: 237

-

10-05-2015, 06:11 PM #1480

Some ideas in this thread! http://straightrazorpalace.com/works...ng-blades.html

"Don't be stubborn. You are missing out."

I rest my case.

13682Likes

13682Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote