Results 881 to 890 of 4688

Thread: The Butchered Blade

-

09-19-2015, 06:09 AM #881

-

-

09-19-2015, 03:40 PM #882

-

09-19-2015, 03:45 PM #883

-

The Following User Says Thank You to MikeT For This Useful Post:

outback (09-19-2015)

-

09-19-2015, 03:58 PM #884

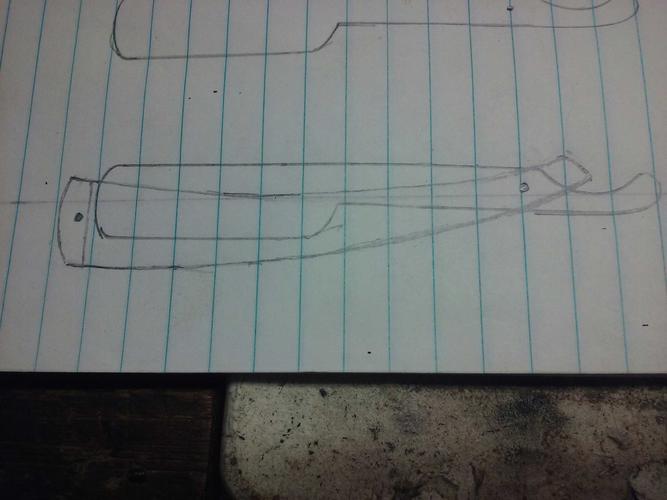

Well I drew one sketch last nite, and thats what I'm going with.

Watcha think.......? Mike

Mike

-

09-19-2015, 04:05 PM #885

Looks really great Mike. I gotta go. Gotta go to my mother's house for a birthday party. She'll be 89 Tuesday. Have a good one guys........I'm outta here.

-

09-19-2015, 04:36 PM #886

See ya Steve, make sure to check back in later or there will be consequences! Lol hehehe

Looks good Mike! You got a style to your designs that is unique i think. What wood you going with?

Steve said he's gonna be getting into stabilizing, when he does I'm gonna see if I can send him some spalted wood so we can all have some spalted to try out.

Since Tom doesn't make scales, I think it would be cool to make some and send them to him... get him to give me a basic design or description...“You must unlearn what you have learned.”

– Yoda

-

09-19-2015, 06:41 PM #887

Not sure on the wood.

Was possibly thinking about the burl& brass thing. But not sure.

I might have to P. M. ya my number so ya can talk me thru it.

It would really set that style of scales off in my opinion.

Then to figure out what wedge material.

I've also thought about a piece of blood wood i have that would look good with a brass wedge, and pins.

[emoji5] [emoji5] thinkin double wedge pin.

Just for tom, we'll see though.Mike

-

09-19-2015, 10:21 PM #888

May I join in? Where can I get my decoder ring?

I'm limited on tools so I'm taking the slow approach. I have two Sheffield razors that have been sitting around for over a year. I plan to hand sand both the blades, make new scales for one and straighten the scales on the other, them back together, and eventually hone them. So I guess I plan to learn the necessary restoration skills along the way.

The first razor has been removed from the scales and I have started hand sanding with 600 grit wet/dry paper. I'm wondering if I should drop down in grit or keep going with the 600. (Pics coming)

Pics 1 & 2 pre-sanding

Pics 3 shank sanded, blade with only major rust removed

Pic 4 blade face sanded, shank with only major rust removed

Last edited by Leatherstockiings; 09-19-2015 at 10:41 PM. Reason: Adding pics

-

09-19-2015, 11:13 PM #889

It's hard to tell, how bad is it pitted.

If theres alot, I personally start at 80 or 180 or 220.

Is it a wedge, near wedge...?

That will also determine how much metal you can remove.

You can start with 600, then determine weather to go up or down in grit.

Careful not to sand over the edge or spine.

If you haven't already, check out the library on restoring, you'll better understand what the guys are talking about, when we reply to your posts.

I just started doing all this restoring stuff , February of this year, and have restored

(In one way or another) roughly 40 razors.

Some with scales on, some had to be pulled, some replaced.

Here..... We do it all.!!

And will try and help every way possible.

But check the libray, and watch a couple videos, if you haven't.

It's great to have you aboard.

MikeMike

-

The Following User Says Thank You to outback For This Useful Post:

Leatherstockiings (09-19-2015)

-

09-19-2015, 11:19 PM #890

Outback, It's a near wedge.

-

The Following User Says Thank You to Leatherstockiings For This Useful Post:

outback (09-19-2015)

13682Likes

13682Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote