Results 911 to 920 of 4688

Thread: The Butchered Blade

-

09-20-2015, 02:50 PM #911Str8Faced Gent.

- Join Date

- Aug 2013

- Location

- Orangeville, Ontario

- Posts

- 8,456

- Blog Entries

- 1

Thanked: 4207

Nice rescale Job15. That full hollow round nose looks perfect in those skins. micro fasteners are a god send when it comes to test fitting.

I personally love full hollows for their edge and honeability.

Keep em coming gents.

MikeT, I will take another look in the dog drawer at a few of my cracked units, ya never know. Maybe one or two may be salvageable.

Cheers gents.Last edited by MikeB52; 09-20-2015 at 02:52 PM.

"Depression is just anger,, without the enthusiasm."

Steven Wright

https://mobro.co/michaelbolton65?mc=5

-

The Following User Says Thank You to MikeB52 For This Useful Post:

JOB15 (09-20-2015)

-

09-20-2015, 04:24 PM #912

Oh yeah! Looking great man. Don't know what I like the most, usually go for 1/4 to half hollows, but it's fun to change up..

The ebony is always a good choice. I have yet to work with it as the dark wood I've been using is African Blackwood.. not as dark but has its qualities.Last edited by MikeT; 09-20-2015 at 04:34 PM.

“You must unlearn what you have learned.”

– Yoda

-

The Following User Says Thank You to MikeT For This Useful Post:

JOB15 (09-20-2015)

-

09-20-2015, 04:32 PM #913

-

09-20-2015, 07:17 PM #914

Hey guys, I'm back. I logged off yesterday but I'm here now. I went to see my mother for her 89th birthday party & she was doing much better than the last time I saw her. She has Alzheimers & in a heartbeat, she knew who I was, nobody had to tell her who I was, she called me by my name. I thank God for His blessings. There are times she doesn't know who people are & it's sad. I won't say anymore, it's personal & doesn't have to do with what we are doing here on this thread.

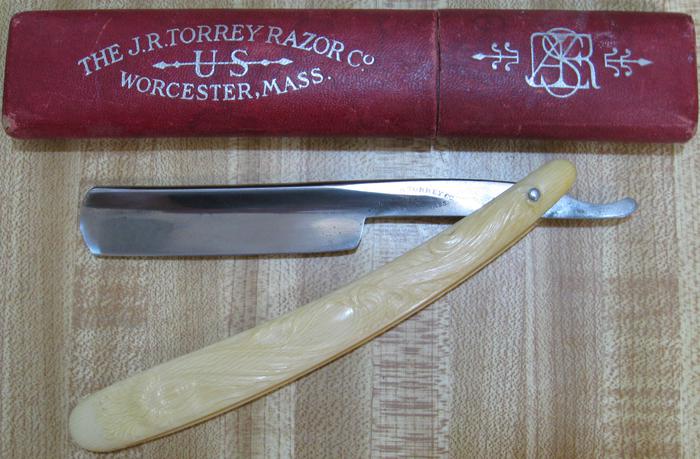

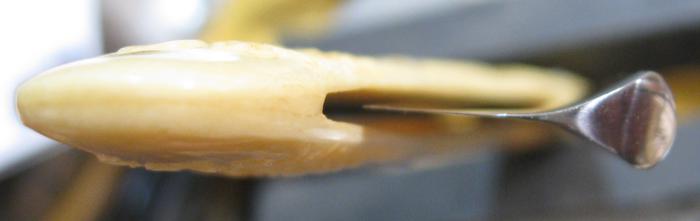

I finished up on my Torrey with the blade I had to grind a chip off the end, then polished the end. I still need to hone it but I will hone about 5 or more razors at one time. I have plenty of tape, 21 rolls so I'm good for awhile. I didn't even post an SOTD like I have been & I think I had a good one this time. It was going to be different but I'll post it next Saturday night. Here's my Torrey. I annealed the ends of the nickel silver so it would be softer since I didn't use collars rather I pinned it in the good ole' Torrey way & annealing the pin about 1/16 on each end kept it from expanding inside the scales possibly cracking or breaking them. it centers beautifully & I used oversized pivots but I use a carbide drill to drill the hole out in the tang. It works fine if you do it right. If I remember right, Tom said that was a no-no but in this case it was a yes-yes. Sorry Tom no offense intended:

Last edited by engine46; 09-20-2015 at 07:36 PM.

-

09-20-2015, 07:40 PM #915

[QUOTE=Leatherstockiings;1543816]May I join in? Where can I get my decoder ring?

I'm limited on tools so I'm taking the slow approach. I have two Sheffield razors that have been sitting around for over a year. I plan to hand sand both the blades, make new scales for one and straighten the scales on the other, them back together, and eventually hone them. So I guess I plan to learn the necessary restoration skills along the way.

The first razor has been removed from the scales and I have started hand sanding with 600 grit wet/dry paper. I'm wondering if I should drop down in grit or keep going with the 600. (Pics coming)

Hell yeah, c'mon brother. No decoder ring or a even certain color rat rink needed! Join in the fun..............

-

The Following User Says Thank You to engine46 For This Useful Post:

Leatherstockiings (09-20-2015)

-

09-20-2015, 08:09 PM #916

Leatherstockings, I have wet or dry sandpaper from 240 grit on up to 3000 grit so I would wet sand it in progressions. It doesn't look like that bad of a blade. If you don't have a lot of different sandpaper, go to Home Depot or Lowes & get a variety pack which should help out. That will be a nice razor when done.

Last edited by engine46; 09-20-2015 at 08:12 PM.

-

09-20-2015, 08:23 PM #917

I put in another hour of sanding with the 600 grit this afternoon. It looks like there are only a couple of spots with heavy pitting, the shank and high up on the blade face.

The wife is out of town with the car so I'm stuck with 600 and 1200 grit. My father-in-law picked me up various grit sandpaper packs at the hardware store today so I should make some progress this week. Meanwhile, I wiped the blade down with WD 40.

-

09-20-2015, 08:33 PM #918

-

09-20-2015, 08:41 PM #919

-

09-20-2015, 08:48 PM #920

1/4 Hollows are my favourite. I have one that I don't shave with anymore because its a Holy Relic , the hairs jumps off before the blade gets to it. At least it feels like that.

I've never liked wooden scales much but I have some rosewood scales that I adore and Ebony is nice. I do like wooden scales that are finished to look like plastic, really shiny. I have a lot of Hart Steel wooden scales, dull and boring.

13682Likes

13682Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote