Results 1,631 to 1,640 of 20599

Thread: What are you working on?

-

01-07-2016, 10:52 AM #1631I love Burls....... and Acrylic

- Join Date

- Mar 2012

- Location

- Baden, Ontario

- Posts

- 5,475

Thanked: 2284

You can just see the parchment paper box in the last photo.

Burls, Girls, and all things that Swirl....

Burls, Girls, and all things that Swirl....

-

01-08-2016, 05:17 PM #1632Senior Member

- Join Date

- Sep 2014

- Location

- Bulgaria

- Posts

- 840

Thanked: 168

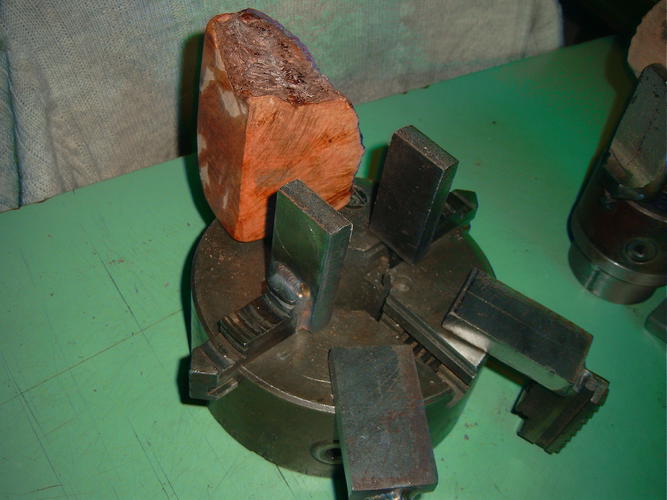

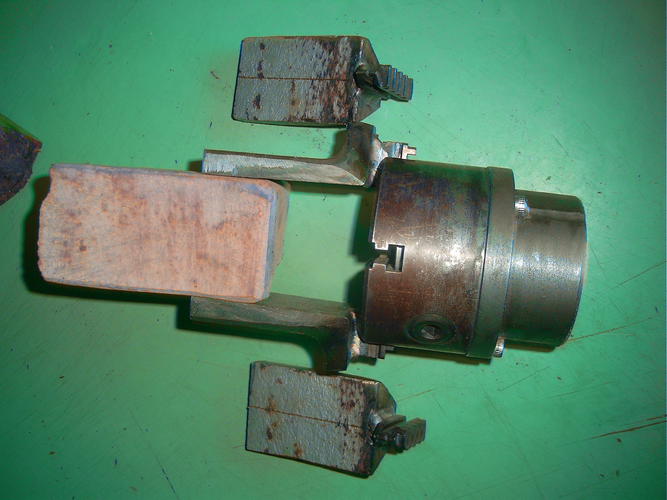

I just gett new buffing mashine with 2 weels 25 sm each and i gen my jaws , with new piecess of iron welded

A good big new Jaws for pipmaking and holding briar pieces

The welding is a speciall universal welding for allkinds of steel and metals - Argon welding

-

01-08-2016, 05:19 PM #1633Senior Member

- Join Date

- Sep 2014

- Location

- Bulgaria

- Posts

- 840

Thanked: 168

-

01-08-2016, 05:25 PM #1634

-

01-08-2016, 05:27 PM #1635

-

01-08-2016, 05:48 PM #1636

'IF' you have other scales of similar color but are 'junkers' you might try this to fill that 'chunk' however they look like horn scales and I'm not sure if the 'trick' would work. With that said, you could always play with a bit of horn dust to find out.

I hope this helps.

http://straightrazorpalace.com/works...ht-razors.htmlOur house is as Neil left it- an Aladdins cave of 'stuff'.

Kim X

-

01-08-2016, 06:33 PM #1637

I was thinking about trying the horn dust idea just to give it a shot. The scales are pretty chewed up though so I will probably need to make new ones or find a donor set!

-

01-17-2016, 01:24 PM #1638

Some things I heat treated yesterday.

Top: San mai I made myself, with a core of O2 and sides of Howard Clark 40 layer Damascus

Bottom: 5 layers of O2 and 15N20 I made myself.

Top: Predator razor in Maarten Van Hattum Damascus. Maarten is a Dutch smith who makes good steel

Bottom: Arwen razor in Wootz. The wootz was made by a Belgian craftsman Evrahim Barran.

When I make layered steel, I always have some end cuts that are not big enough for a razor. I like to turn those into little kitchen knives.

Top: leftover from the 5 layer billet

Middle: leftover from the san mai billet

Bottom: leftover from an old bar of 1095 and 15N20 Damascus.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

Til shade is gone, til water is gone, Into the shadow with teeth bared, screaming defiance with the last breath.

To spit in Sightblinder’s eye on the Last Day

-

01-17-2016, 09:08 PM #1639

Ernie, I have tried the horn dust & it works to a degree but it is sometimes hard to match the colors. I also get emails from Stewart-MacDonald about repairs because I have bought tools from them years ago when I was working on guitars & Dan Erlewine is one very smart man so cuda's link is a good one. I have been saving those emails for years. They also have some good tools for working on straight razors.

As many may know, the 3 primary colors are red, blue & yellow & with those you can make any color but matching is a trick but ink can sometimes be used to make different colors. I was building a circuit board for an amp once & I drilled a wrong hole in some red fiberglass board so I made some dust from a spare piece of it & I filled the hole with it & packed it in there & then put some thin CA in it. It worked out well but when it was dry, it was just slightly lighter in color but was close enough that you really had to look for it to see it. It is cool to experiment with sanded dust, powders etc. & sometimes one can get lucky.

Good luck my friend.Last edited by engine46; 01-17-2016 at 09:13 PM.

-

01-17-2016, 10:27 PM #1640

silver steel warranted wedge and Frederick Reynolds half hollow coming along

-Slow is smooth, smooth is fast-

-Slow is smooth, smooth is fast-

91532Likes

91532Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote