Results 16,981 to 16,990 of 20573

Thread: What are you working on?

-

08-25-2019, 05:59 AM #16981

I'm with ya, Marty. Crocus is a mysterious paper as what it can do. Even at 800 grt., if its continuously used to the point of wore out, it can easily be polished by hand to a mirror/ glazed look.

Or a satin/ brushed look

Last edited by outback; 08-25-2019 at 06:18 AM.

Mike

-

The Following User Says Thank You to outback For This Useful Post:

ScoutHikerDad (08-25-2019)

-

08-25-2019, 11:22 AM #16982

Thanks to you both Marty and Mike. Mine is the 3M (so good quality) 1k crocus cloth you see on ebay. I'll give it a go, though it probably won't happen until Labor Day weekend.

There are many roads to sharp.

-

08-25-2019, 12:27 PM #16983Senior Member

- Join Date

- Apr 2012

- Location

- Diamond Bar, CA

- Posts

- 6,553

Thanked: 3215

You are just going to lay on a satin finish. I cut the paper into a 3x3 inch strip, align one edge of the paper with the edge of a synthetic cork.

With the razor on the bench so that the edge is facing you, put the paper wrapped cork on the belly at the bottom edge of the spine and so the edge of the cork is in the corner where the belly of the blade meets the stabilizer. Then pull the cork straight down and rotate the cork slowly towards the spine, so that when you reach the edge you have rotated about a ¼ turn.

This will cause fresh new paper to cut as you make the pull, this works with 600 grit also. You should only need 2-3 pulls with lite to medium pressure, if you are working on a buffed surface.

Now slide the cork to the other side of the paper so you are on new paper and hang the edge of the cork off the toe about 1/8 – ¼ inch and do another set of pulls to finish the other half of the blade. You can turn the paper 90 degrees and get 2 more new surfaces if needed.

As Mike said Crocus does last a long time and can polish to near mirror, which is why machinist use it for polishing bearing surfaces.

If you use it after 600 or 1k it will easily polish to a mirror with a good metal polish, (3m Marine is my favorite since Mike turned us on to it a while back, and a tub last forever) and paper towel, the rougher the towel the better, I like the blue shop towels or paper hand towels sold in stackable folded sheets as used in public restrooms. They are cheap and polish well. I invested in a wall hanging dispenser. Or buff with Black Magic or Green Chrome greased compound and a spiral sewn or loose wheel.

-

The Following User Says Thank You to Euclid440 For This Useful Post:

ScoutHikerDad (08-25-2019)

-

08-25-2019, 05:57 PM #16984

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

08-25-2019, 06:59 PM #16985

Got in #7 of the seven day set of Imperial Extra Hollow Ground. The point has been either intentionally or accidentally broken off. I have done this before with really sharp square points albeit to a much less noticable degree.

So informal poll here. Do I:

A) square it back off

B) round point it or

C) leave it?

I think I already know what the consensus will be.Iron by iron is sharpened, And a man sharpens the face of his friend. PR 27:17

-

08-25-2019, 07:14 PM #16986

Leave it alone..... Please.!

Reset the bevel and hone it, that should minimize its appearance.Mike

-

08-25-2019, 07:55 PM #16987

Marty-Definitely going to give your method a try.

And Paul-I have sanded hollow blades before; these are just deeply pitted/scratched/spotted, and I know I can't get through that without running out of steel. I'm pretty sure I can hide it well using Marty's technique.

I also have to factor in a decade's old recurring carpal tunnel in my dominant left hand (which is also my grading hand-not to mention my honing and stropping hand) which started from repetitive motion working my way through college in a Stouffer's Foods plant in the 80's. I only sand if I have to, especially during the school year!There are many roads to sharp.

-

08-25-2019, 09:32 PM #16988

-

08-25-2019, 09:38 PM #16989

-

08-25-2019, 10:26 PM #16990

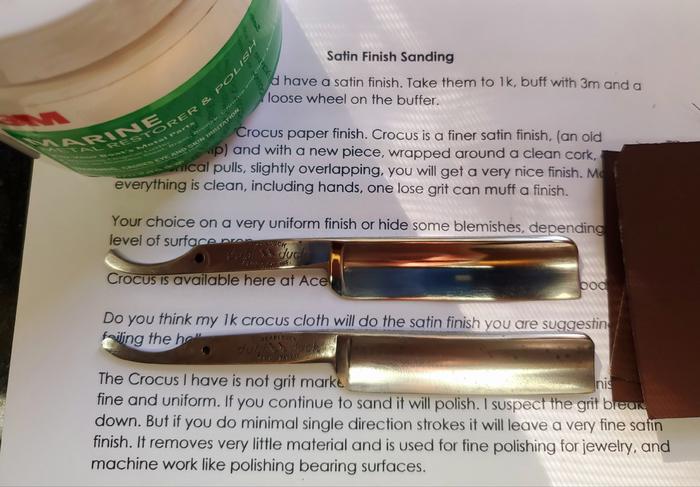

So I copied some of Marty's detailed advice to make printed notes for my shop notebook (yeah, I keep one and it comes in real handy!), and here's where I'm at. This may seem unconventional, but I secured each blade in my rubber-lined knife vise and started working on it with the 3M crocus, using 3M Marine polish as my sanding/polishing lube and working the hollows evenly on both sides. Being careful not to put any vertical fulcrum pressure on it, I sanded both blades and tangs for awhile, building up a thick brown mud as the rouge in the cloth broke down.

After wearing out a few of my 3" crocus squares, I buffed each one on a loose wheel with Fabuluster, and ended up here:

Now that they're polished, you can really see the scratches, pitting and spots lol! I may drop back to 600 next weekend and then repeat the 3M polish with the crocus cloth.

Then I plan to either go full satin with the 600-grit vertical lines on the blade faces and keep the tang and spine shiny, or just satin all over-we'll see. Either way, it will be a huge improvement over what I had. Thanks again for the ongoing help all! Now I've gotta go review Heart of Darkness! SHDThere are many roads to sharp.

91474Likes

91474Likes LinkBack URL

LinkBack URL About LinkBacks

About LinkBacks

Reply With Quote

Reply With Quote